Automatic leveling device of gas holder piston

A technology for automatic leveling and gas cabinets, which is applied in the direction of adjustable capacity gas storage tanks, gas/liquid distribution and storage, mechanical equipment, etc. Rapid adjustment and other problems to achieve the effect of solving the tilt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

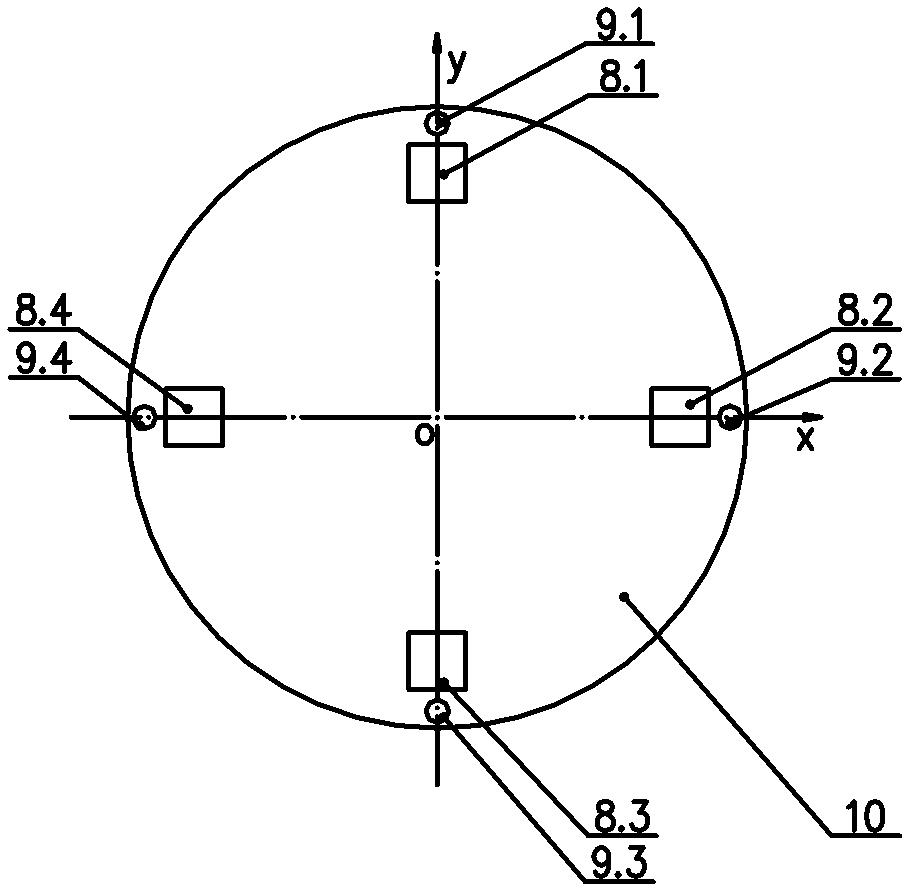

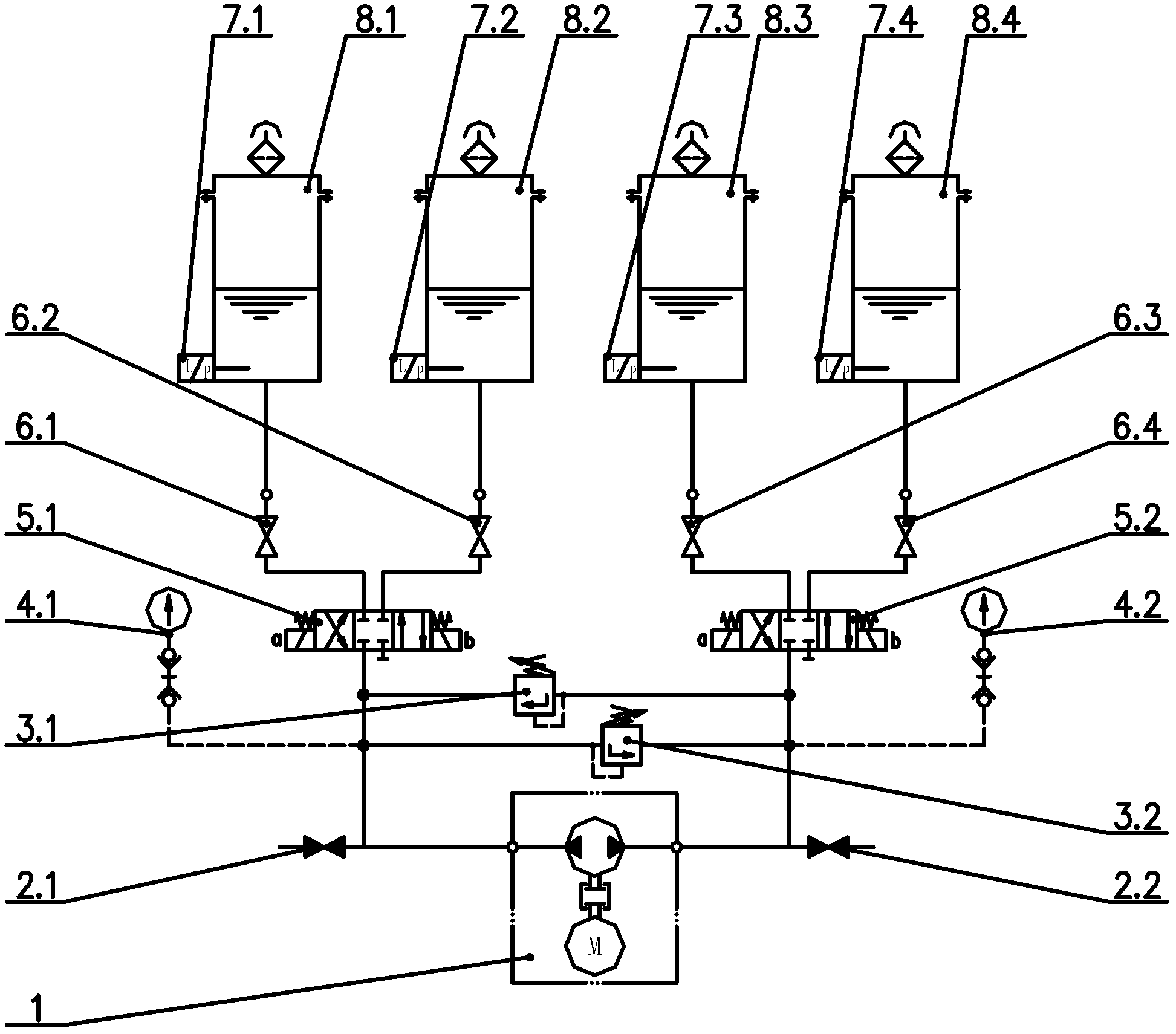

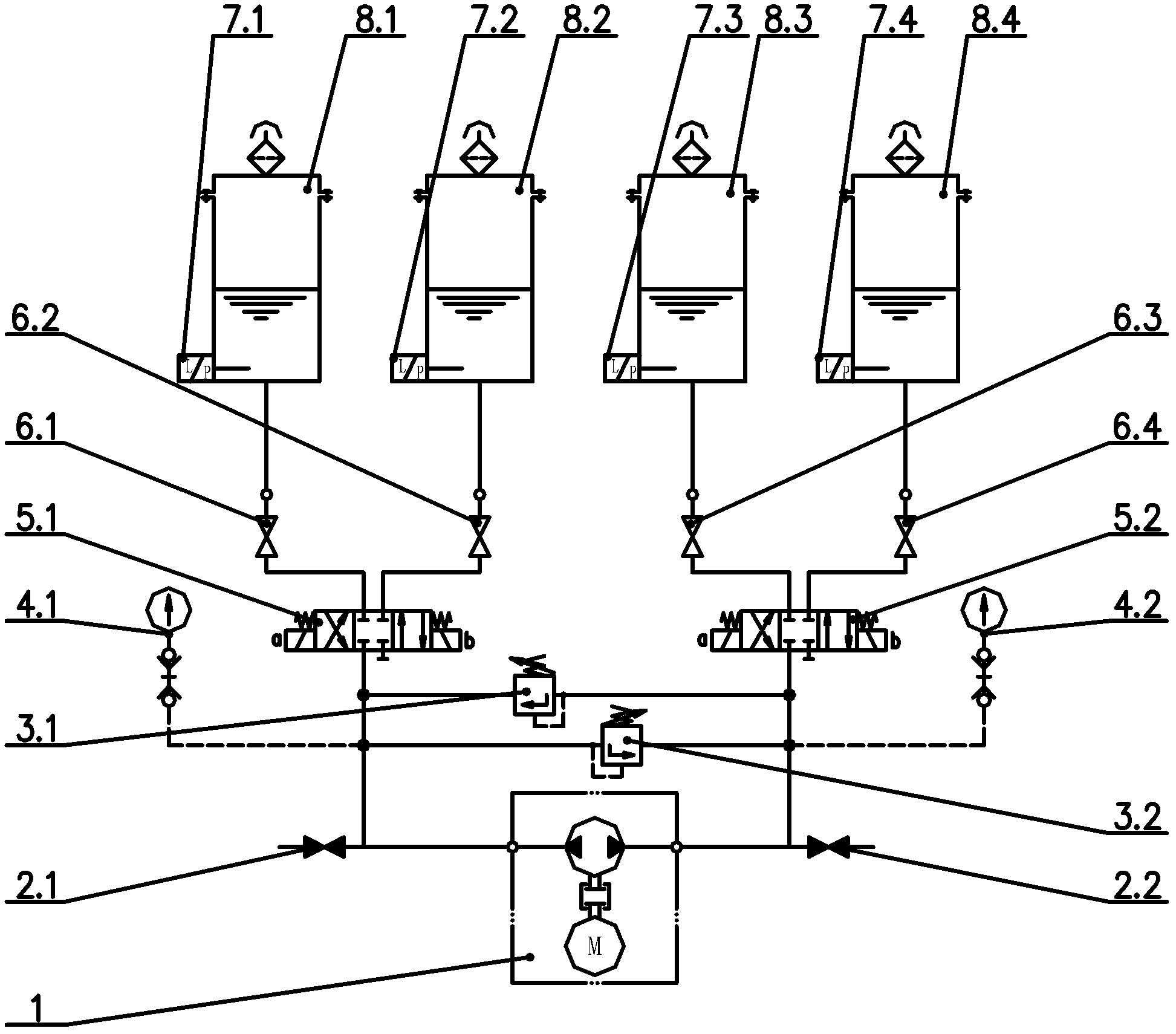

[0020] Such as figure 1 and 2 As shown, the gas tank piston automatic leveling device of the present invention mainly includes: bidirectional fluid pump motor unit 1, fluid adding and discharging ball valve 2 (including 2.1 and 2.2), safety valve 3 (including 3.1 and 3.2), pressure gauge assembly 4 (including 4.1 and 4.2), solenoid valve 5 (including 5.1 and 5.2), ball valve 6 (including 6.1-6.4), liquid level gauge 7 (including 7.1-7.4), counterweight box 8 (including 8.1-8.4), piston level Detector 9; Fluid is housed in the counterweight box 8, which can be oil or water, but not limited to oil or water as a counterweight; four counterweight boxes 8 and four piston level detectors 9 are respectively symmetrically distributed on the piston 10 along the circumference , each counterweight box 8 and its corresponding piston level detector 9 are located on the same radius; the weights of the four counterweight boxes are the same or the weight and shape are the same; the weights o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com