Special equipment for repairing tower seal surface

A sealing surface, machine tool technology, applied in the direction of manufacturing tools, boring/drilling, metal processing equipment, etc., can solve the problems of high repair cost, long construction period, affecting production and operation, etc., to achieve the effect of short repair construction period and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

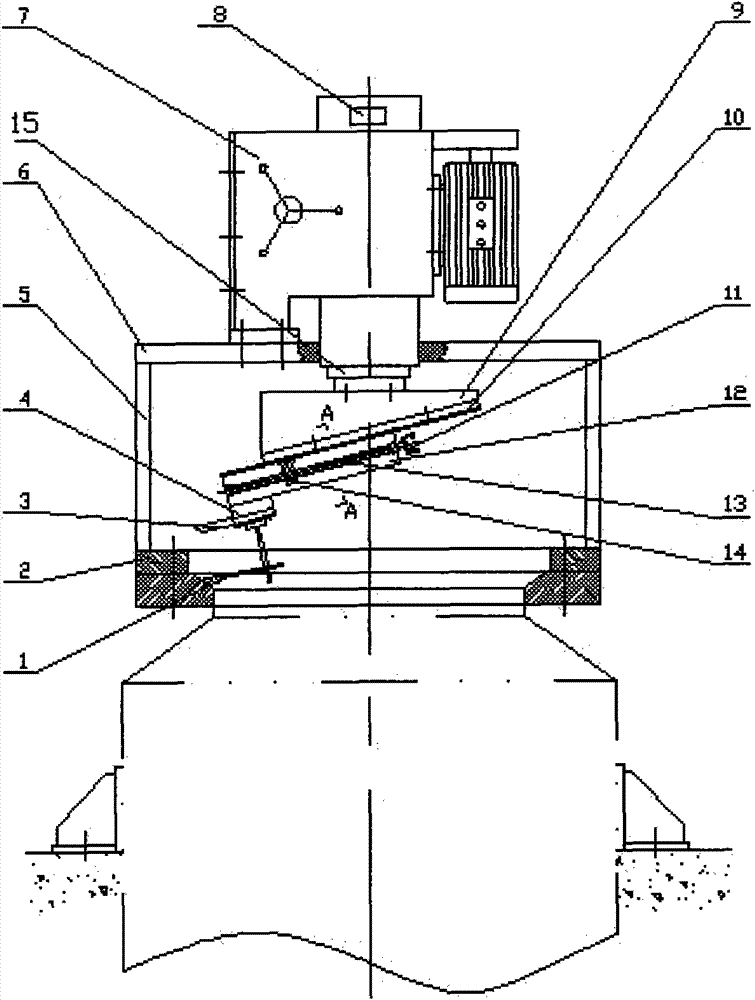

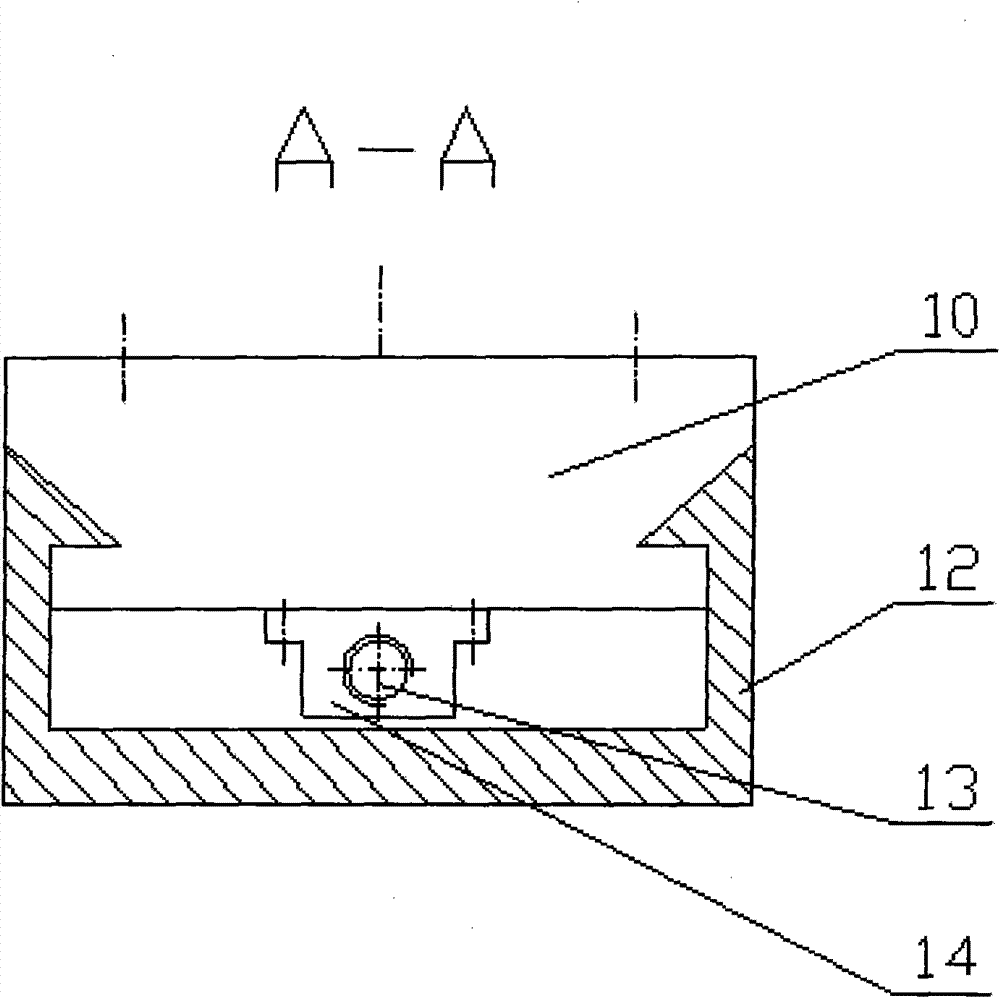

[0010] see figure 1 , 2 , the present invention includes a power head 7 and its main shaft 15, and the power head 7 is fixed upside down on the frame. The frame is designed according to the flange surface of the tower mouth. The frame is composed of the upper platform plate 6, the lower flange plate 2 and four Φ30 round steel pillars 5 supported by the middle connection; the lower flange plate 2 and the tower mouth are connected by tower bolts. fixed. The power head 7 is fixed on the upper platform plate 6 of the frame by bolts. The main shaft 15 connects the machine tool rest with it through the wedge-shaped coupling disc 9 . The implement knife rest comprises a knife rest base 10, and the knife rest base 10 is fixed on the wedge-shaped connecting disc 9, and the slide seat 12 on the knife rest is fed by a leading screw 13, a drive nut 14, and the knife rest 4 fixes the cutter head 3. Lead screw 13 end is provided with handle 11, is used for adjusting upper sliding seat 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com