Extrusion molding device of glass-magnesium board material

A technology for extrusion molding and glass magnesium sheet, which is applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of affecting the thickness uniformity of the sheet, no display device, and difficulty in adjusting the thickness of the sheet, so as to achieve convenient operation, stable process, Adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

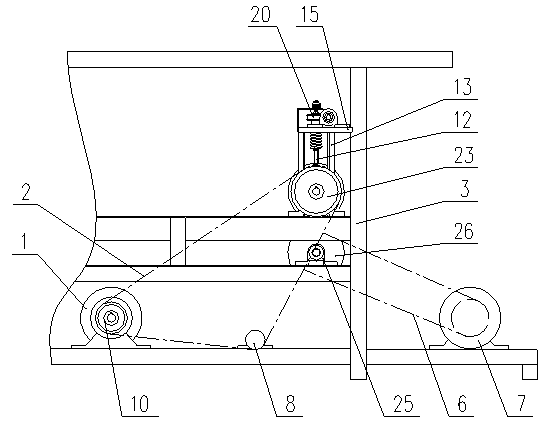

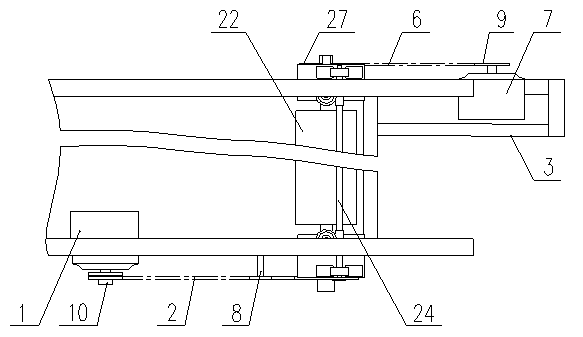

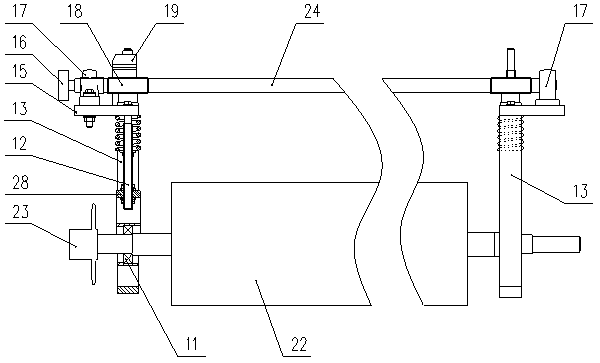

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the glass magnesium plate extrusion molding device includes: a mounting bracket 3, an upper extrusion roller 22 and a lower extrusion roller 26 are arranged in the installation bracket 3, and the lower extrusion roller 26 is arranged through the connecting shaft at its two ends In a pair of bearings with seats 25, the bearings with seats 25 are installed in the mounting bracket 3; two pairs of parallel guide rails 13 are fixedly installed on the mounting bracket 3, and each pair of parallel guide rails 13 is provided with a bearing slider seat 28, The band bearing slider seat 28 can slide up and down in the parallel guide rails 13, and the upper squeeze roller 22 is supported in the bearing 11 in the band bearing slider seat 28 by the connecting sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com