Ratchet box with set-up function

A ratchet wrench and toolbox technology, which is applied in the direction of manufacturing tools, tool storage devices, etc., to achieve the effects of reliable turning mechanism, optimized structure space, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

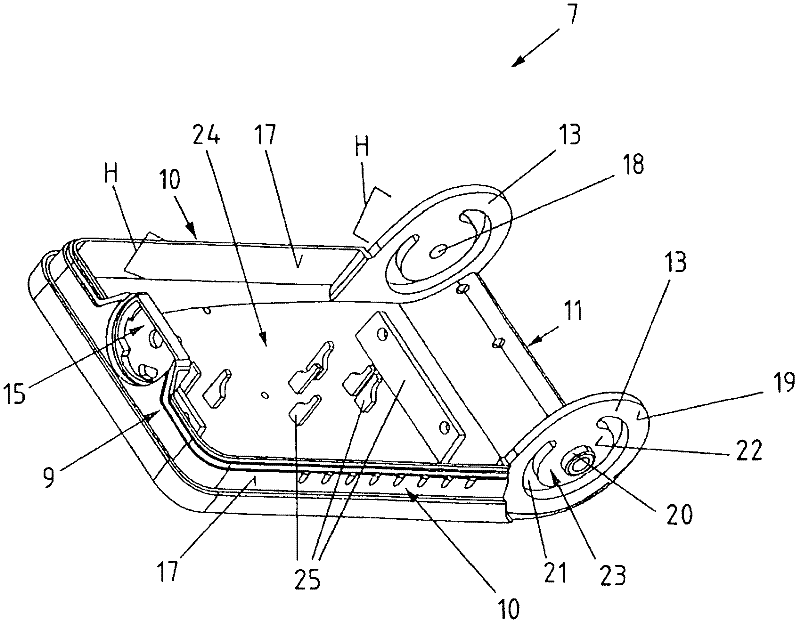

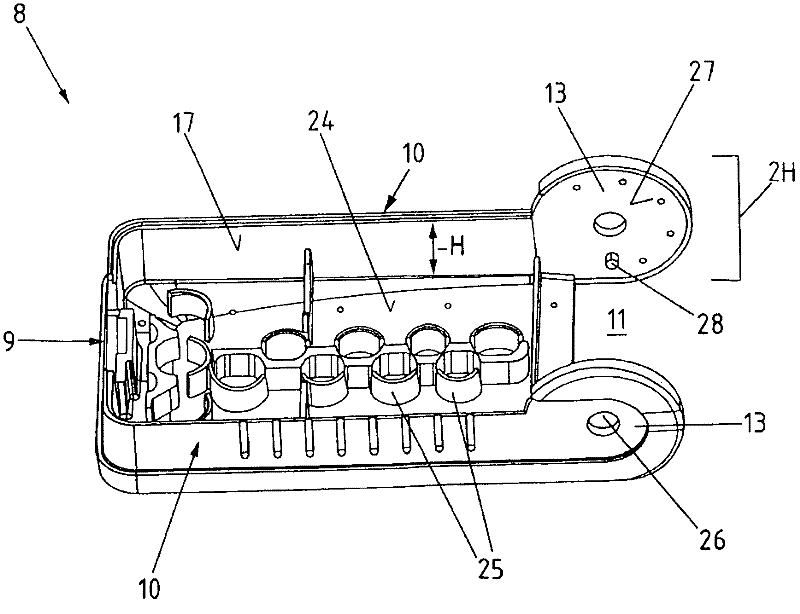

[0046] In the figures, the same reference numerals are used for the individual components, even if a repeated description is omitted for reasons of simplification.

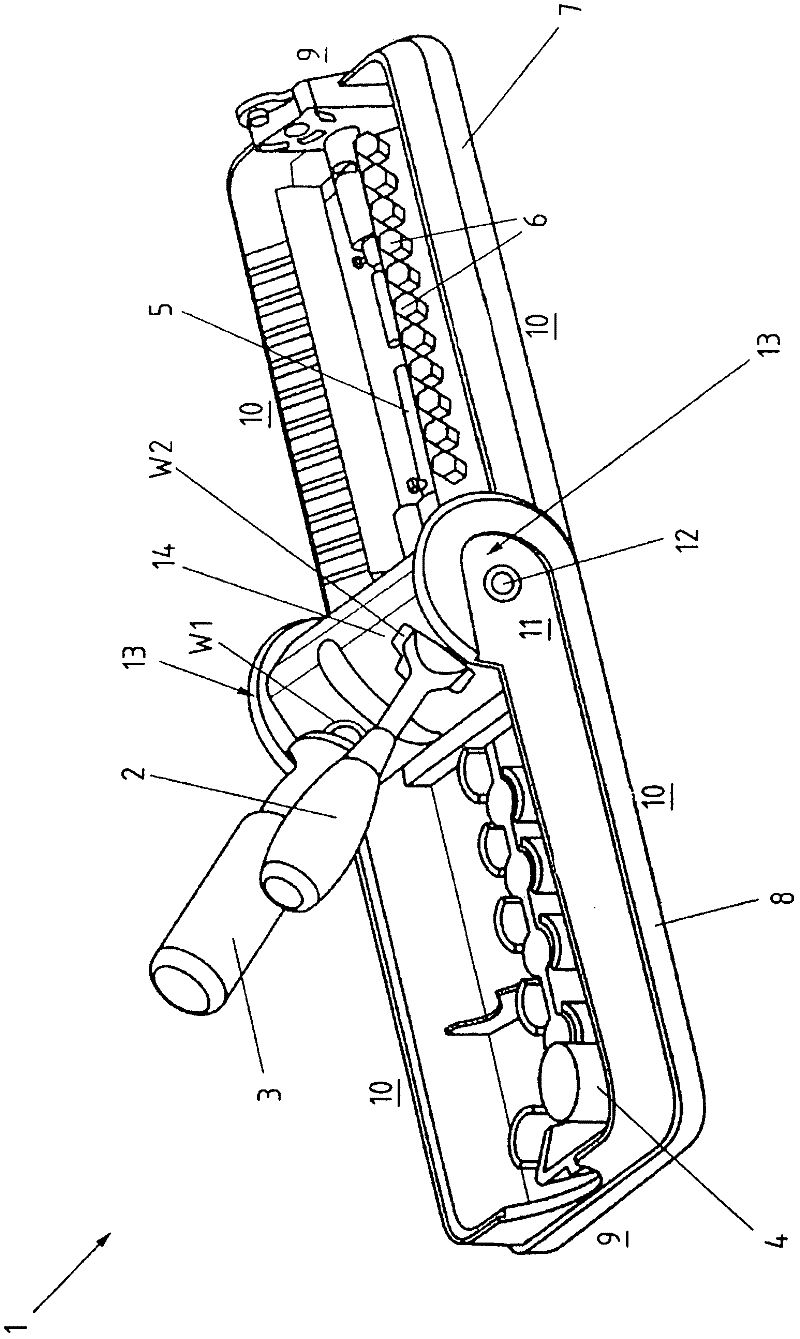

[0047] figure 1 A perspective view of the tool case 1 of the present invention is shown. The tool case 1 is intended to receive a socket wrench set, here described in the form of a ratchet 2 and handle 3 inserted into tool receptacles W1 and W2 and various socket wrench sets 4. Extension pieces 5 and various plug-in cutter heads 6. The aforementioned socket wrench set is received in a fixed position in the tool case 1 .

[0048] The tool case 1 comprises an upper housing part 7 and a lower housing part 8 which are rectangular and cup-shaped. The lower housing part 8 and the upper housing part 7 each have a front side 9 , a rear side 11 and two longitudinal sides 10 . The housing parts 7 , 8 are each pivotably coupled to one another on their rear sides 11 about a pivot axis 12 via a plate 13 . Arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com