Device and method for evaluating displacement capability of wetting phase of rock at high temperature under high pressure

A high-temperature, high-pressure, wetting phase technology, applied in the field of petroleum industry, can solve the problems of not considering the influence of temperature and pressure effects on the displacement efficiency of wetting phase, the inability to simulate the reservoir environment, and experimental errors, so as to achieve true and reliable experimental conditions , strong operability and reliable principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Further illustrate the present invention below in conjunction with accompanying drawing.

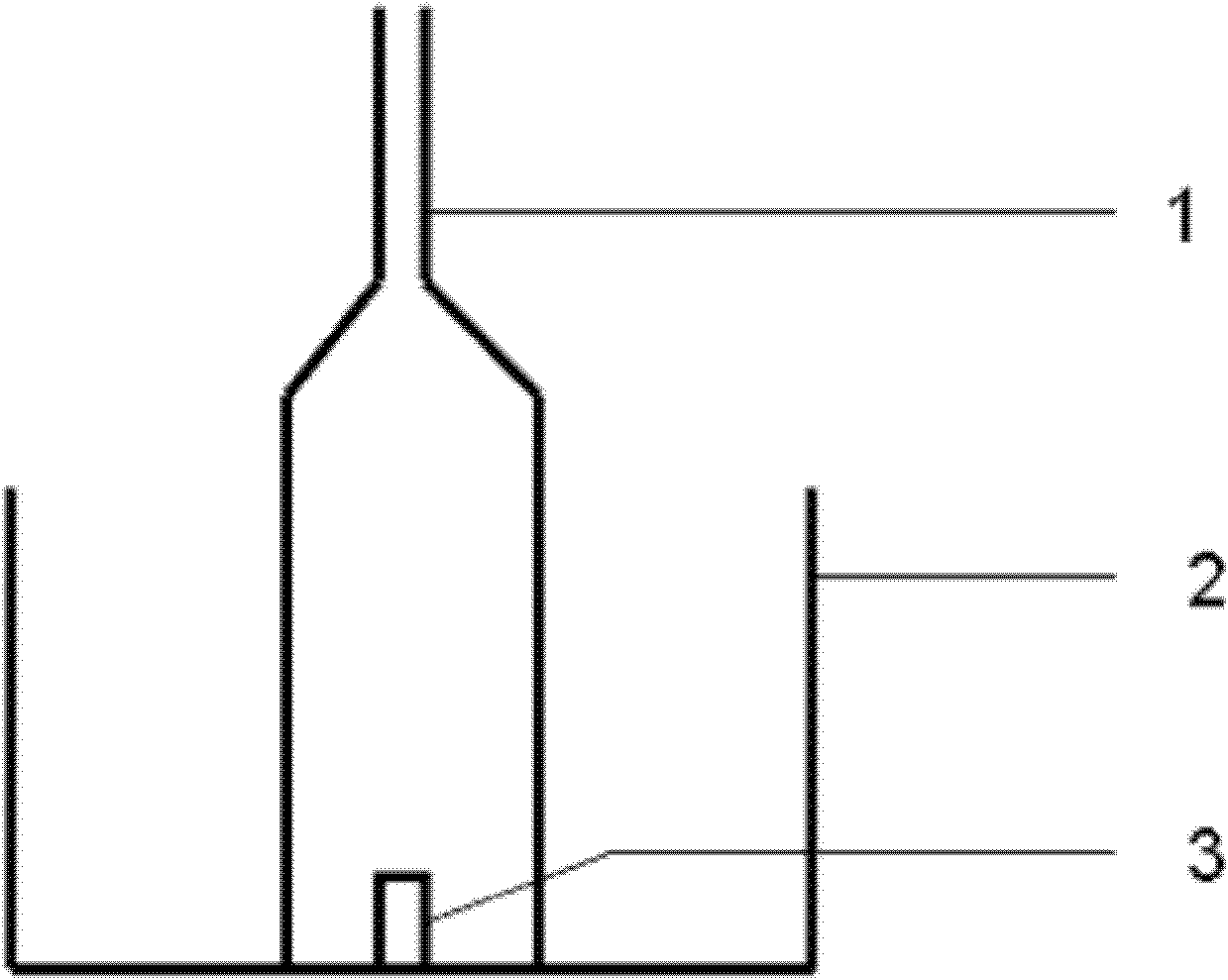

[0041] See figure 1 . figure 1 It is a traditional displacement measurement device, and the simulated injection water is placed in the glass tank 2; the core 3 is placed in the center of the tank, so that the core is completely immersed in the water in the simulated injection water environment; the glass cover 1 is put into the tank and the core Surrounded, and then start the water flooding experiment, the separated oil will automatically enter the upper part of the glass cover under the action of gravity, so as to record the amount of oil produced.

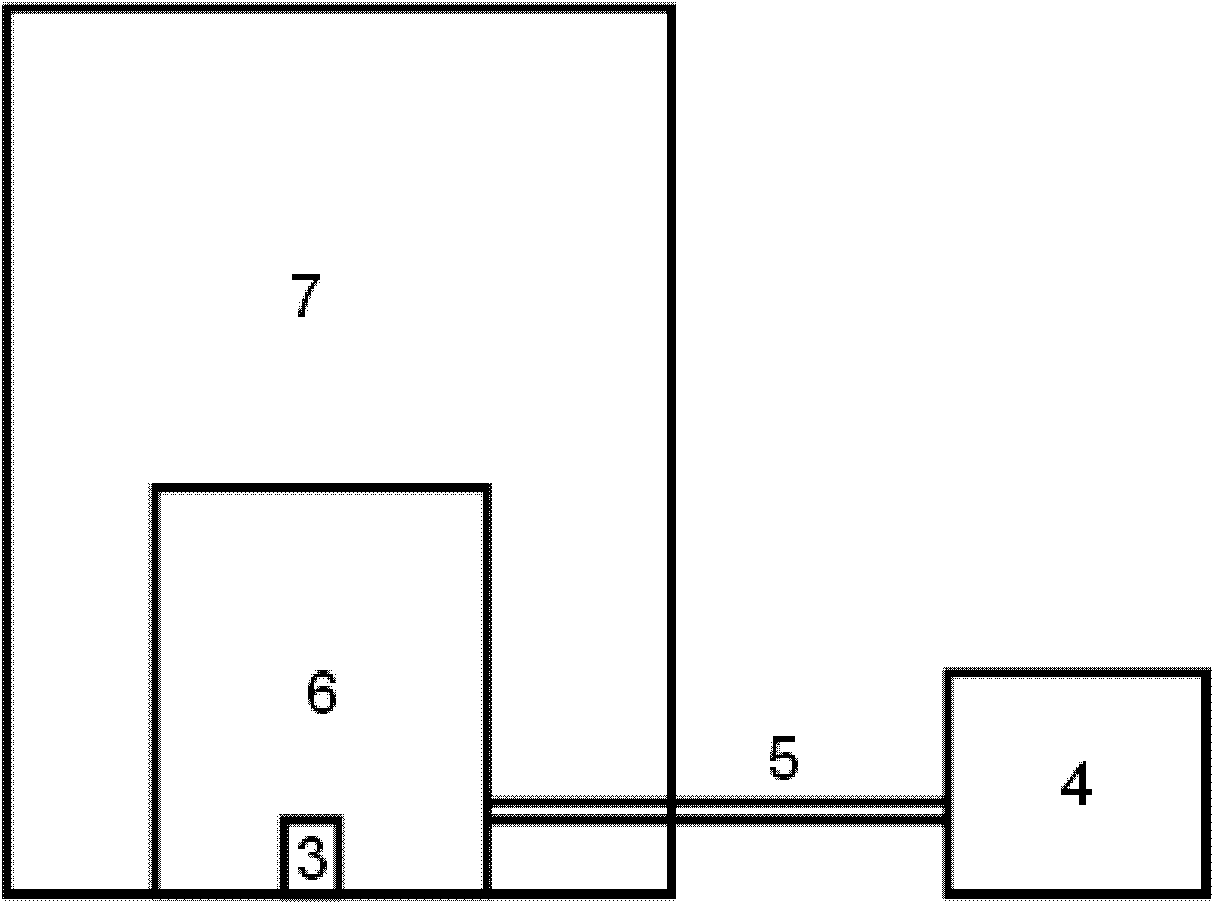

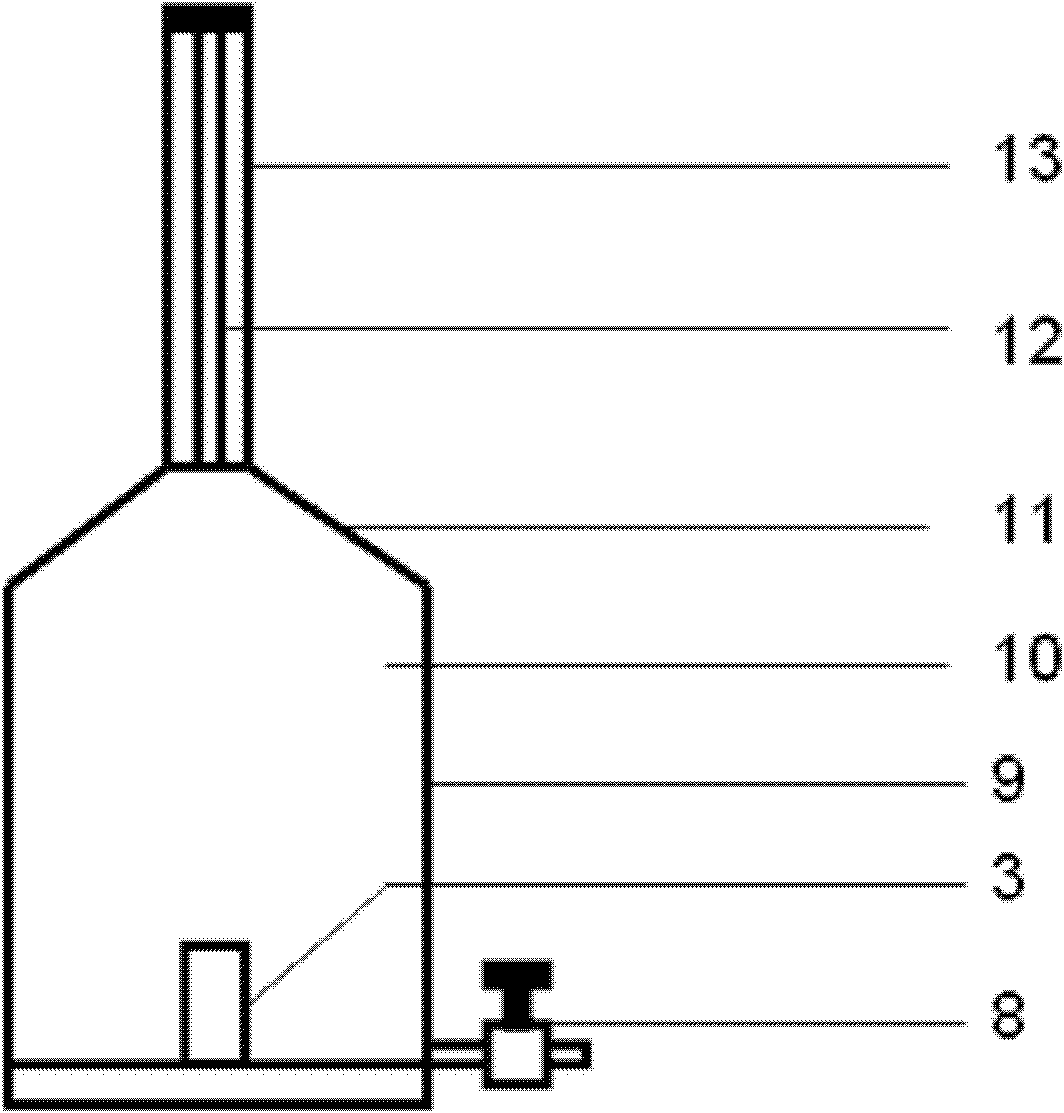

[0042] See figure 2 , image 3 .

[0043] A device for evaluating the displacement ability of rock wetting phase under high temperature and high pressure, mainly composed of a displacement device 6, a constant temperature box 7 and a pressure pump 4, the displacement device is located in the temperature control box, and the disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com