Double-compensation feeding cutting device and battery winding equipment

A double compensation and feeding technology, applied in the direction of winding strip, thin material processing, transportation and packaging, etc., can solve the problems of increasing equipment downtime, the positive and negative plates cannot be cut at the same time, and reducing the operating efficiency of the equipment. The effect of saving cutting time, saving equipment space and improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below through embodiments in conjunction with the accompanying drawings.

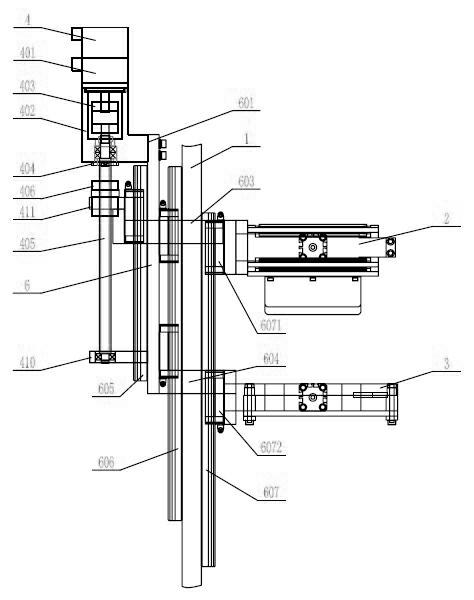

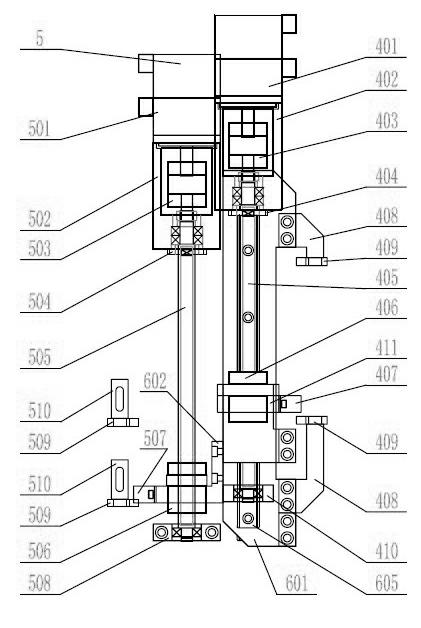

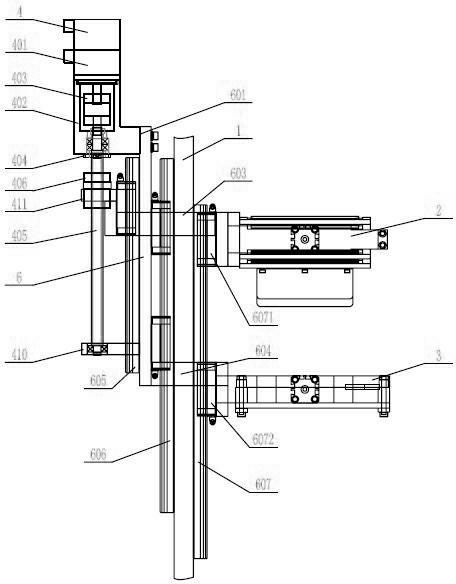

[0020] see figure 1 and figure 2 , in one embodiment, the double compensation feeding and cutting device includes a feeding mechanism 4, a clamping mechanism 2, a cutting mechanism 3 and a pole piece detection component (not shown in the figure), and the feeding mechanism 4 drives the clamping mechanism 2 to relatively cut Mechanism 3 moves, and pole piece detection component can be arranged on cutting mechanism 3, and it can detect pole piece, for example the pole position of pole piece, also can cooperate with cutting mechanism in other ways, detects the relative position of pole piece to cutting mechanism. As an improvement to the prior art, the double compensation feeding and cutting device of this embodiment also includes a cutting compensation mechanism 5, which drives the feeding mechanism 4 and the cutting mechanism 3 to move sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com