Self-positioning system and self-positioning method for coal mining machine

A self-positioning and coal mining machine technology, which is applied in the direction of earthwork drilling, cutting machinery, instruments, etc., can solve the problems of lack of self-positioning function, high labor intensity, low degree of automation and intelligence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

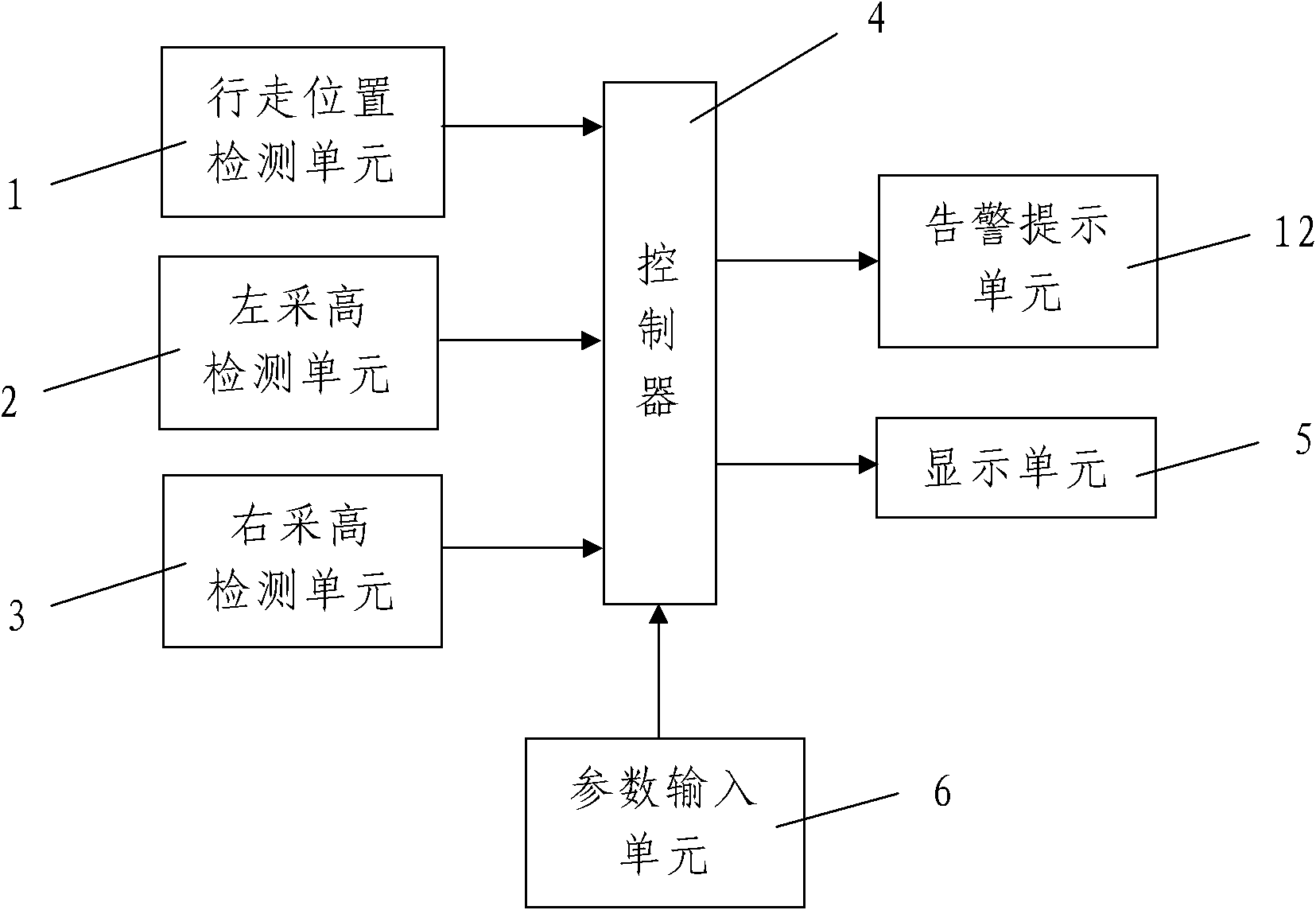

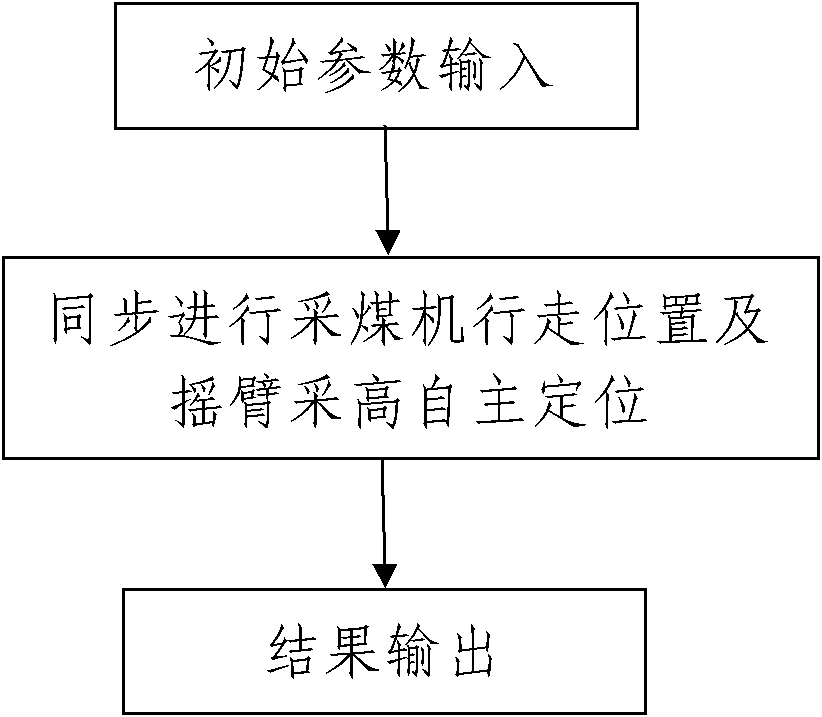

[0054] Such as figure 1 The self-positioning system of a shearer shown includes a controller 4, a walking position detection unit for real-time detection of the walking position of the shearer, and a left mining machine for real-time detection of the mining height of the left rocker arm 8 of the shearer. The height detection unit 2, the right mining height detection unit 3 for real-time detection of the mining height of the right rocker arm of the coal shearer, and the display unit 5 and the parameter input unit 6 respectively connected with the controller 4, the walking position detection unit, Both the left mining height detection unit 2 and the right mining height detection unit 3 are connected with the controller 4 .

[0055] In this embodiment, in actual use, the walking position detection unit 1 , the left mining height detection unit 2 and the right mining height detection unit 3 are all connected to the controller 4 through a CANBUS field bus. Among them, CANBUS (abbr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com