Parallel pipe jacking construction simulation device

A technology for simulating device and pipe jacking, which is used in pipeline laying and maintenance, pipes/pipe joints/fittings, mining equipment, etc., and can solve problems such as inability to realize research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

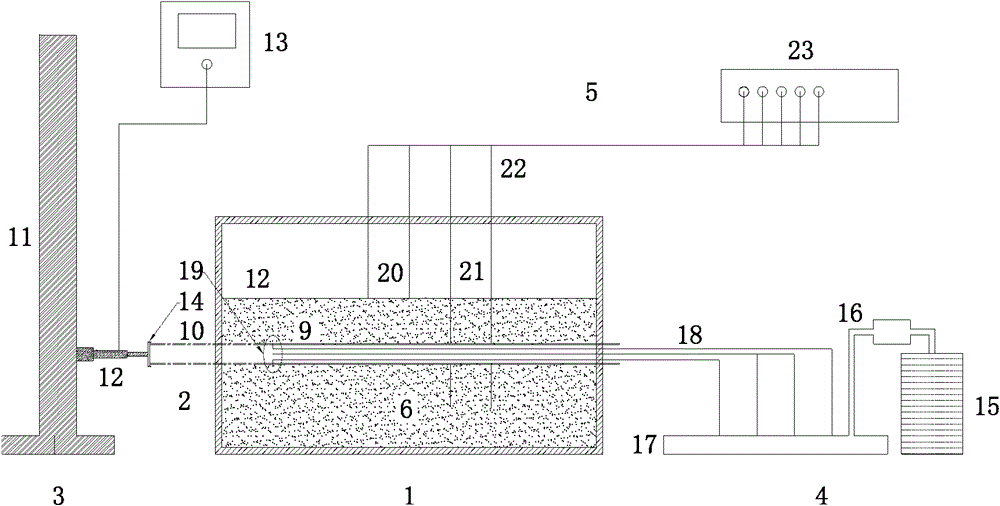

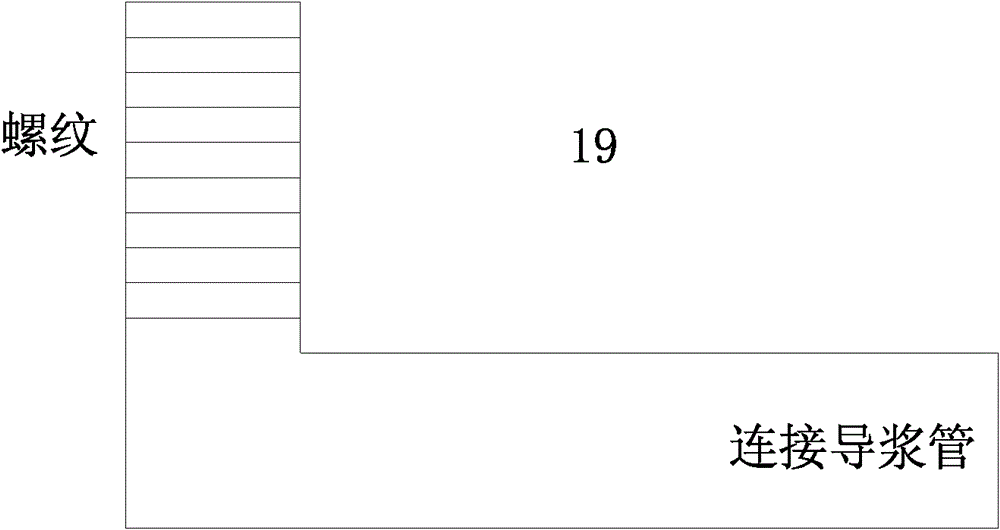

[0037] Such as figure 1 As shown, this embodiment includes: a simulation box 1, a connecting pipe joint 2, a support mechanism 3, a construction simulation mechanism 4 and a test module 5, wherein: the simulation box 1 is provided with a simulated soil 6 and a plurality of connecting pipe joints 2 runs parallel to the inside of the simulation box 1, the support mechanism 3 and the construction simulation structure are respectively arranged at both ends of the connecting pipe section 2, and the test module 5 is connected to the simulation box 1.

[0038] The simulation box 1 adopts a coverless device made of plexig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com