Grain unloading device for harvester

The technology of a grain unloading device and a harvester is applied in the field of grain unloading devices and grain unloading devices for harvesters. The effect of reducing labor intensity and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

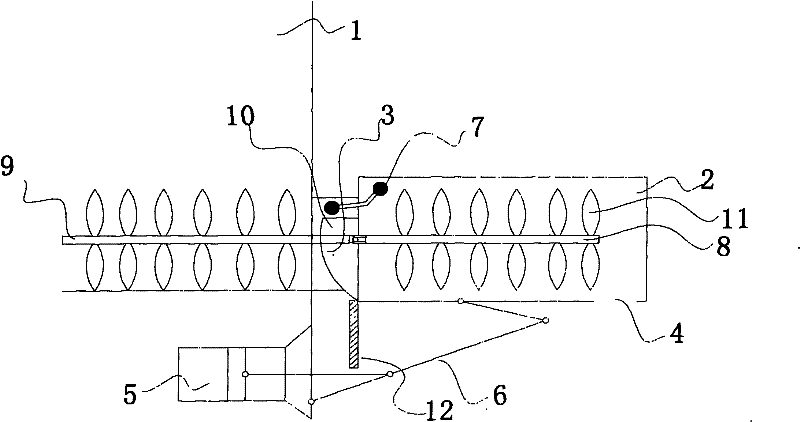

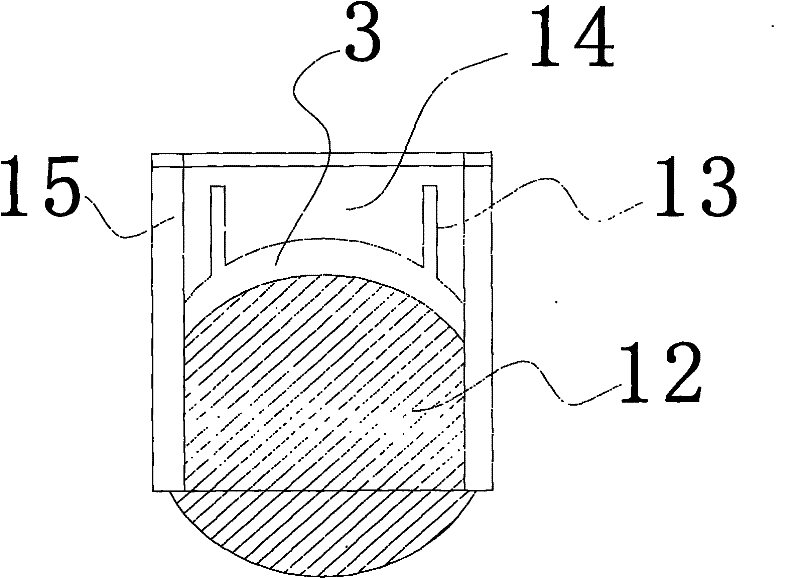

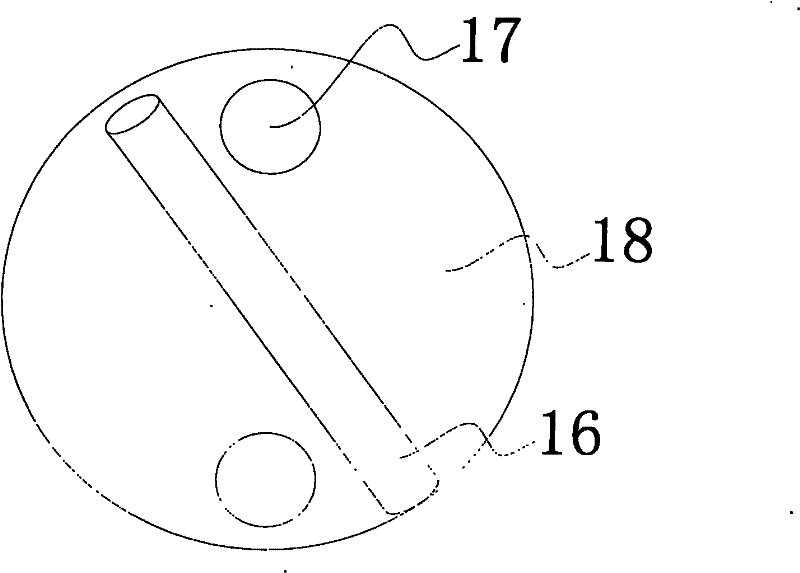

[0026] see figure 1 , the present invention provides a grain unloading device for a harvester, the grain unloading device for a harvester includes a baffle part for blocking the grain outlet, a baffle pushing mechanism, a grain unloading cylinder 2, and a grain unloading cylinder turning mechanism; The grain unloading barrel turning mechanism drives the grain unloading barrel 2 to turn over; the baffle plate components include the back plate 14 and the baffle plate 12 inserted on the back plate 14; the baffle plate pushing mechanism pushes the baffle plate 12 to slide up and down on the back plate 14; The baffle pushing mechanism is arranged on the grain unloading cylinder 2 or on the turning mechanism of the grain unloading cylinder;

[0027] The overturning device for the grain unloading cylinder includes an overturning arm 6 for overturning the grain unloading cylinder 2 and an overturning arm drive unit 5 connected with the overturning arm 6 . Turnover arm drive unit 5 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com