Method for cyclically operating coke oven banks from "heat recovery" coke oven chambers

A technology of cycle operation and coke oven group, which is applied in the direction of steam generation method using heat carrier, coke oven heating, combustible gas heating coke oven, etc., to achieve the effect of small homogenization and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

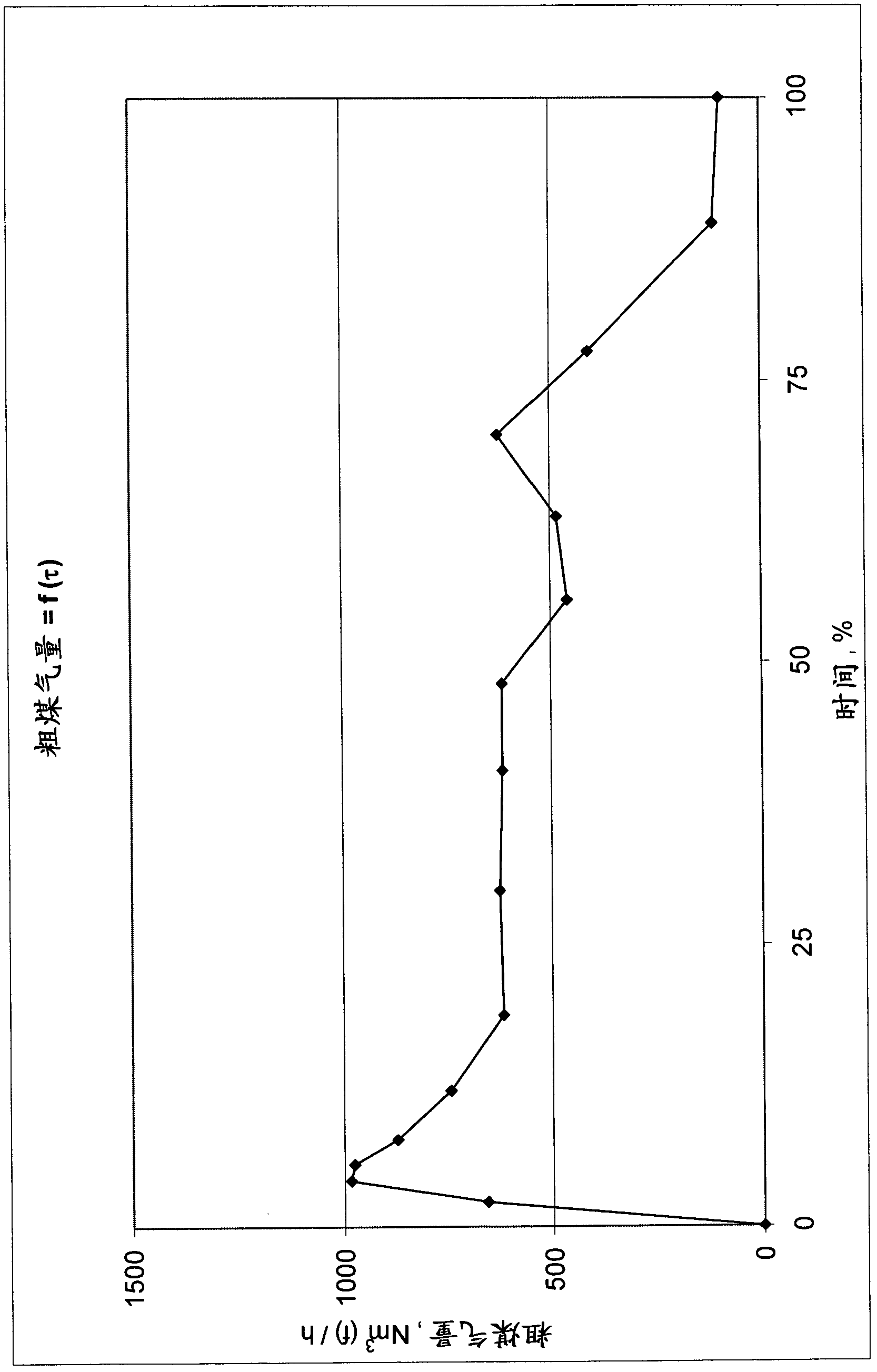

[0050] figure 1 Shows the crude gas amount of coking gas formed above the coke cake during coking and mainly composed of hydrogen, carbon monoxide, methane, and water vapor components. The amount of crude gas is determined in volume units of standard cubic meters per hour throughout the coking cycle. The amount of raw gas is directly proportional to the amount of fully burned coking gas, which flows into the coke oven chamber as combustion gas.

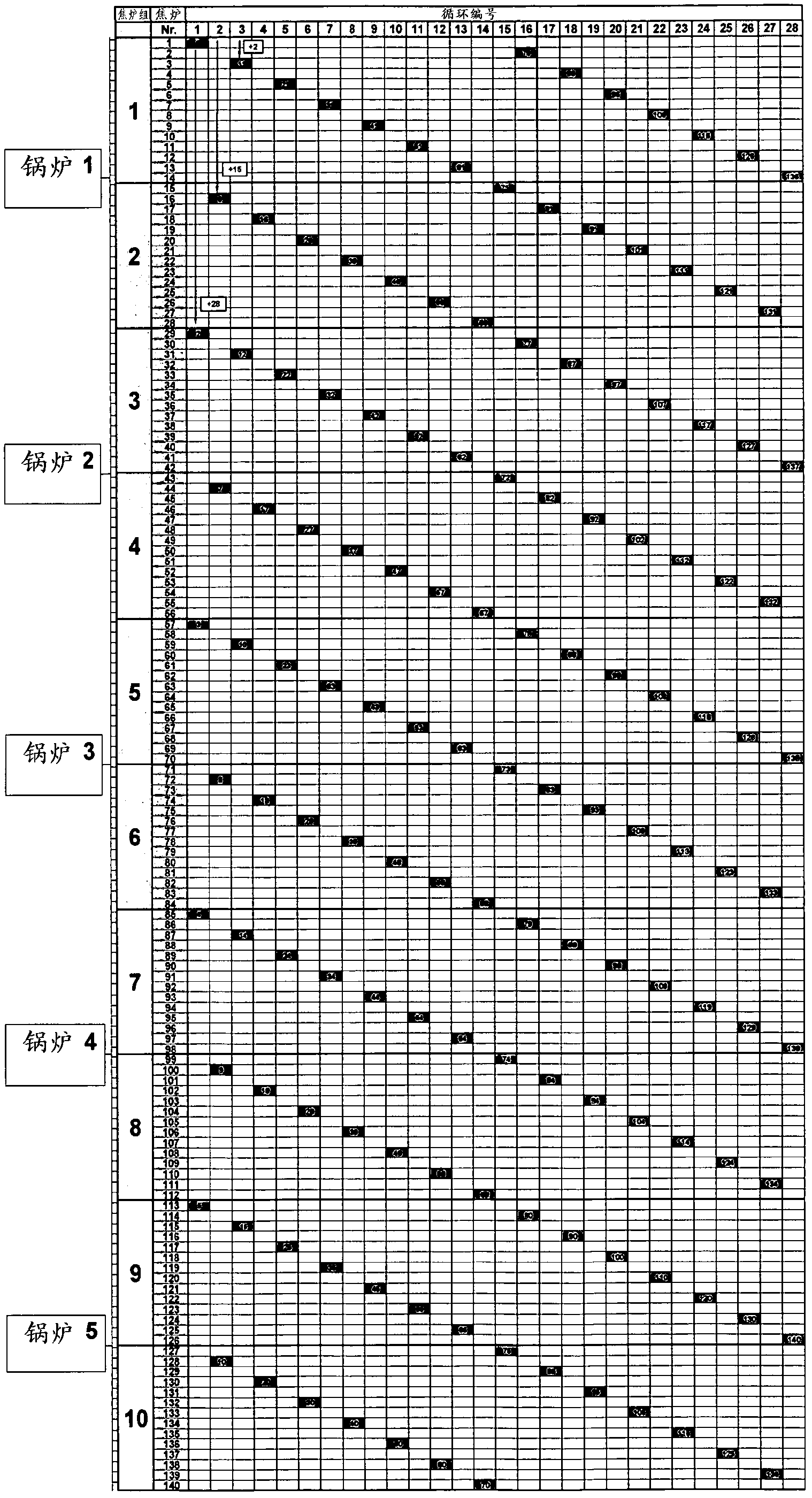

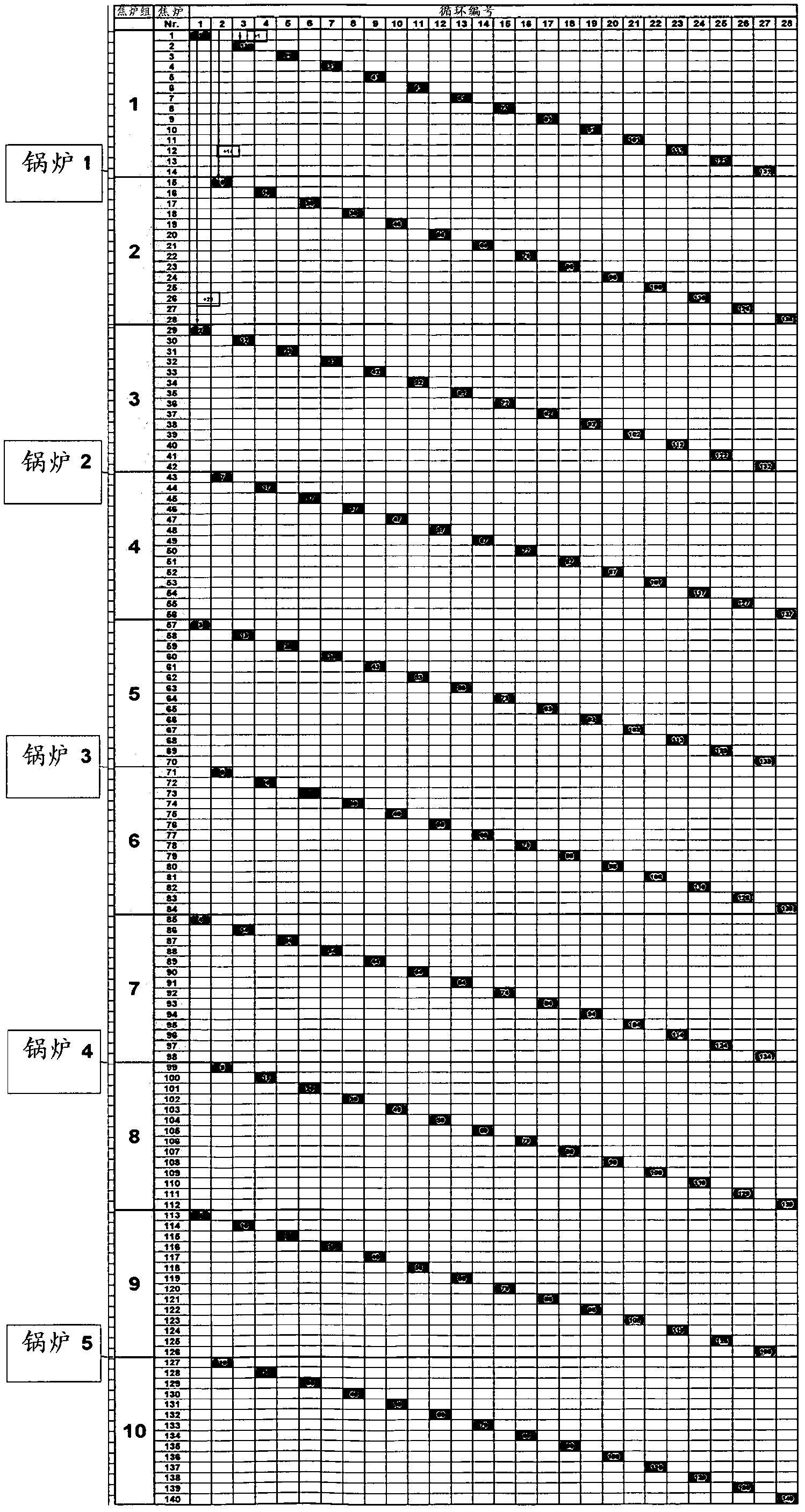

[0051] Figure 2 shows the cycle plan for the "charging-coking-pushing" cycle including the 28 / 15 / 2" coke pushing plan. Each small rectangular block represents a coke oven chamber arranged as a coke oven bank. Each coke The oven groups are numbered in the first column of the illustration and are vertically delimited by columns (Balken). These columns are numbered from 1 to 10. Each coke oven battery consists of 14 coke oven chambers; Numbered in the second column with a number from 1 to 140. The times of the individual cycles are ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com