Multi-functional torque calibration device

A calibration device and multi-functional technology, which is applied in the direction of measuring devices, force/torque/power measuring instrument calibration/testing, instruments, etc., can solve the error in the input itself, the detection and calibration requirements cannot be scientifically reasonable, and the calibration cannot be scientifically accurate. Accurately evaluate the input and output characteristics of the torque multiplier to achieve high-precision torque calibration and improve torque calibration capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

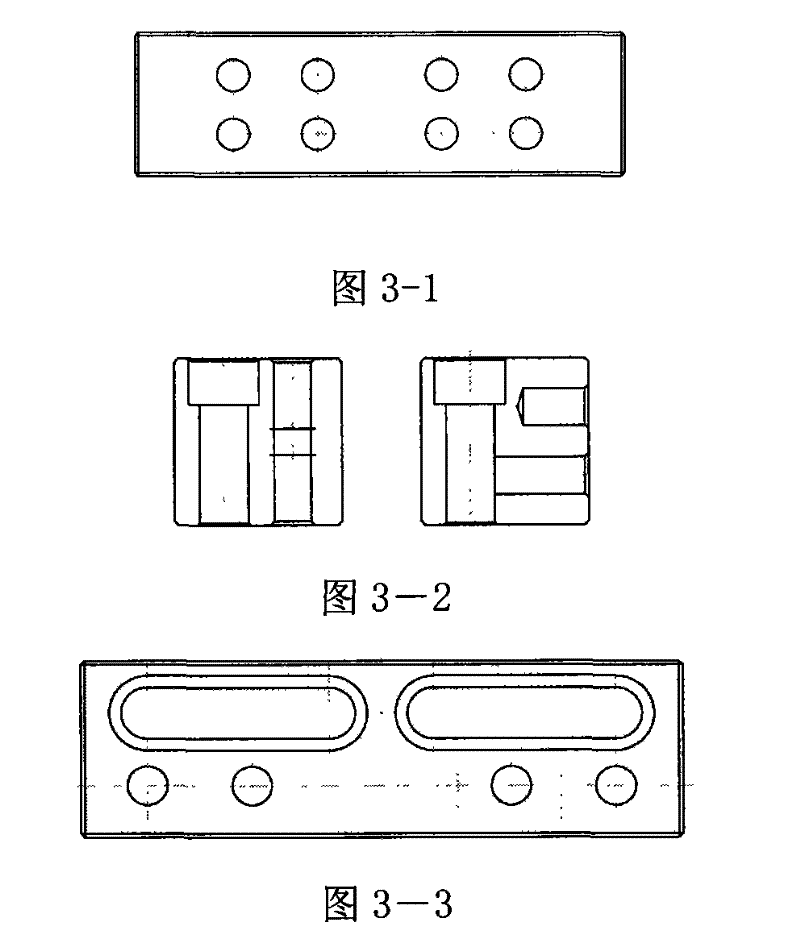

[0026] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0027] Such as figure 1 As shown, a multifunctional torque calibration device, the device includes a basic base 10 and a triangular support structure.

[0028] The triangular support structure includes a first group of columns 9, a second group of columns 3 and a third group of columns 2;

[0029] The first group of columns 9 is installed on the upper end face of the foundation base 10, including three columns distributed in an equilateral triangle, a worktop 7 is installed at the middle and lower part of the first group of columns 9, and the first group of columns 9 passes through the worktable 7 (in figure 1 Among them, the first group of columns is marked as 4) after passing through the workbench, and a top fixed table 15 is installed on the top of the first group of columns 9;

[0030] The third group of columns 2 includes two columns, the bottom of the third gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com