Washing machine

A washing machine and motor technology, applied in the field of washing machines, can solve the problems of unbalanced detection, large vibration, uneven rotation, etc., and achieve the effect of preventing abnormal vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

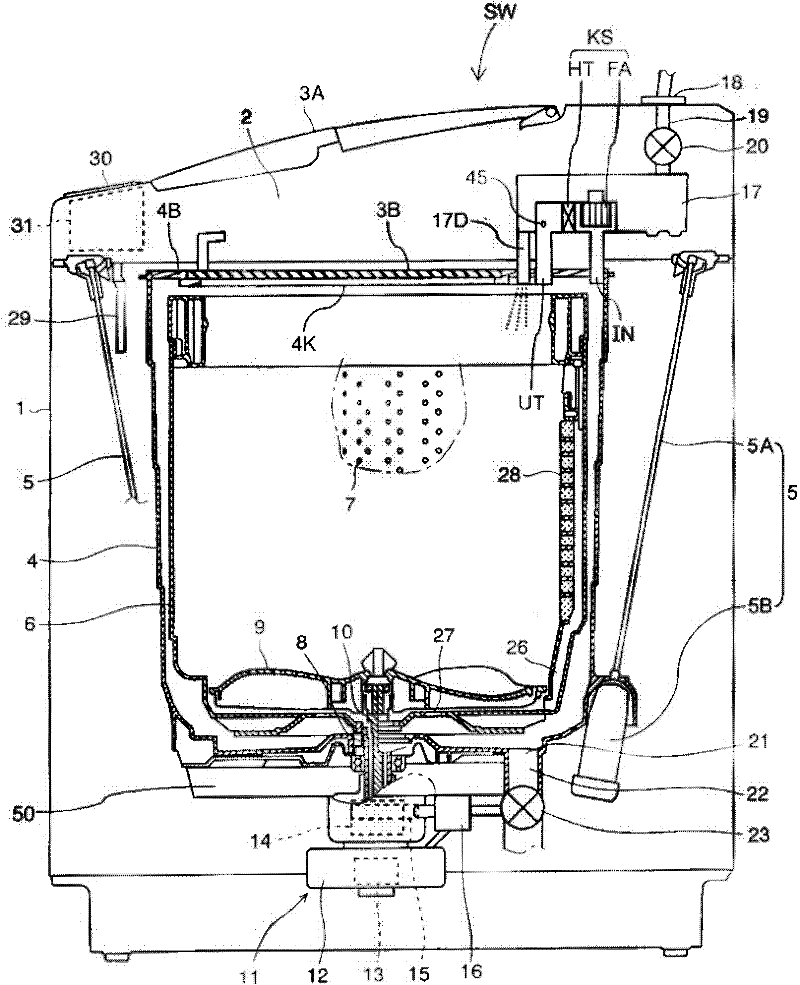

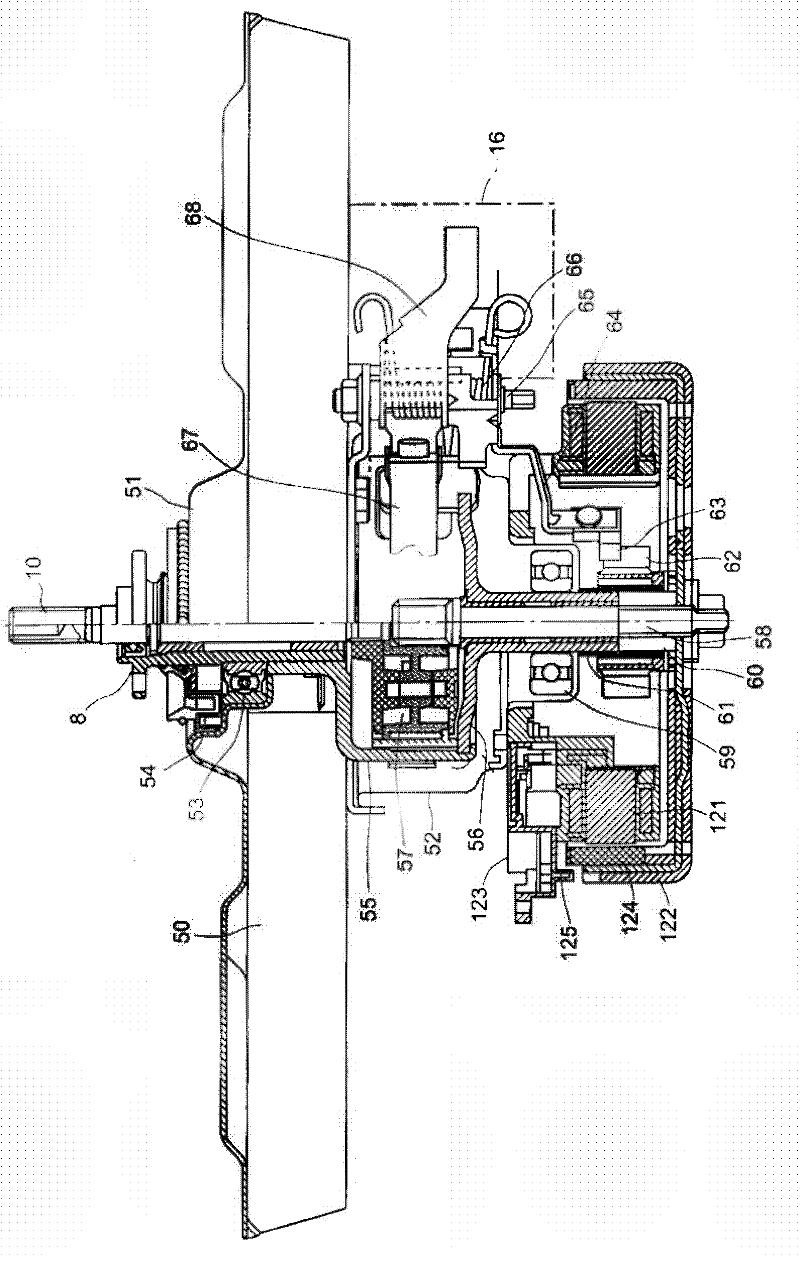

[0149] Next, embodiments of the washing machine of the present invention will be described based on the drawings. In the washing machine SW of the present invention, the inside of the housing 1 with the laundry inlet 2 formed on the top surface is passed through the hanger 5 (in the figure 1 One can be seen in the front and the rear, but in fact there are two in the front and rear respectively) The outer tank 4 made of synthetic resin with a bottomed cylinder is suspended and supported freely, and thereby the vibration of the outer tank 4 is prevented from being transmitted to the The housing 1, wherein the hanger 5 is composed of a hanging rod 5A and a vibration damping mechanism 5B including a coil spring. The laundry inlet 2 can be freely opened and closed by the upper cover 3A that can be folded in half when standing up. Inside the outer tank 4, a washing and dewatering tank 6 having a plurality of water passage holes 7 on the peripheral wall is rotatably supported around...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com