Automatic feeder for woven bag making machine

An automatic feeding and woven bag technology, which is applied in the directions of transportation and packaging, winding strips, thin material processing, etc., can solve the problem that the automatic feeding device of the woven bag making machine has not been found, which affects the economic benefits of the enterprise and the equipment failure rate Improvement and other issues to achieve the effect of simple structure, easy implementation, and reduced failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

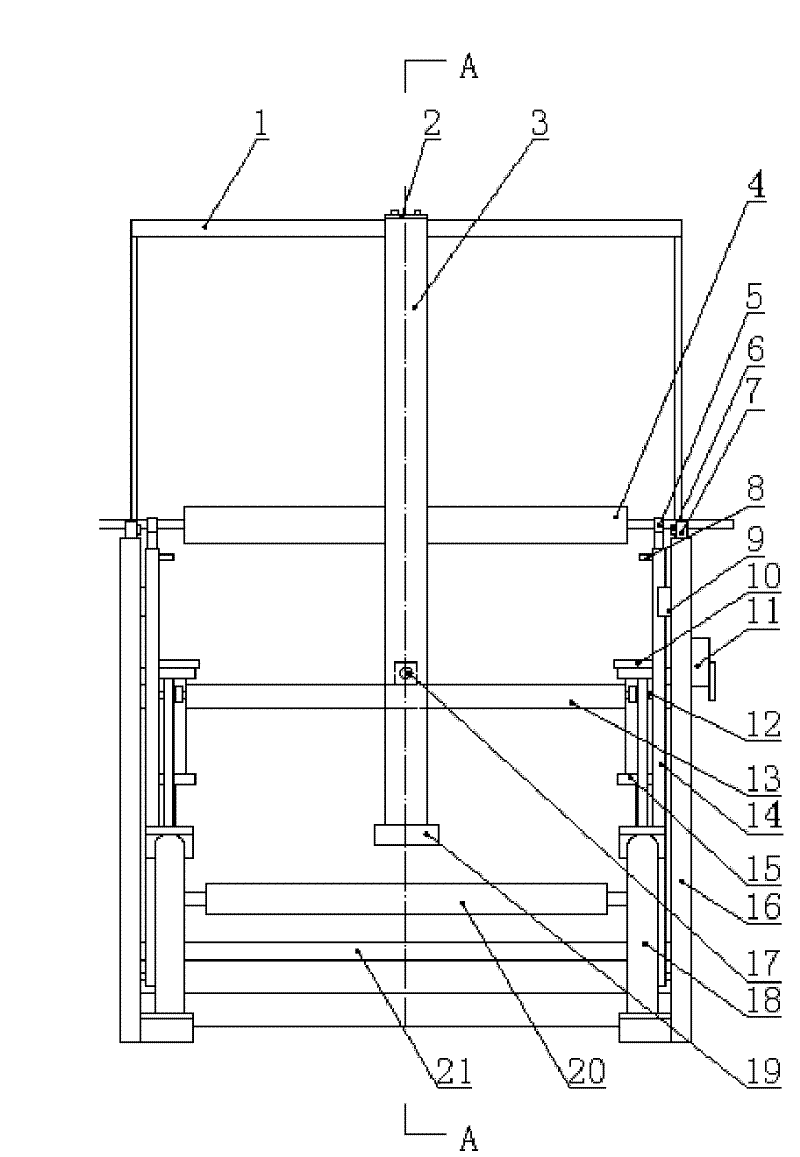

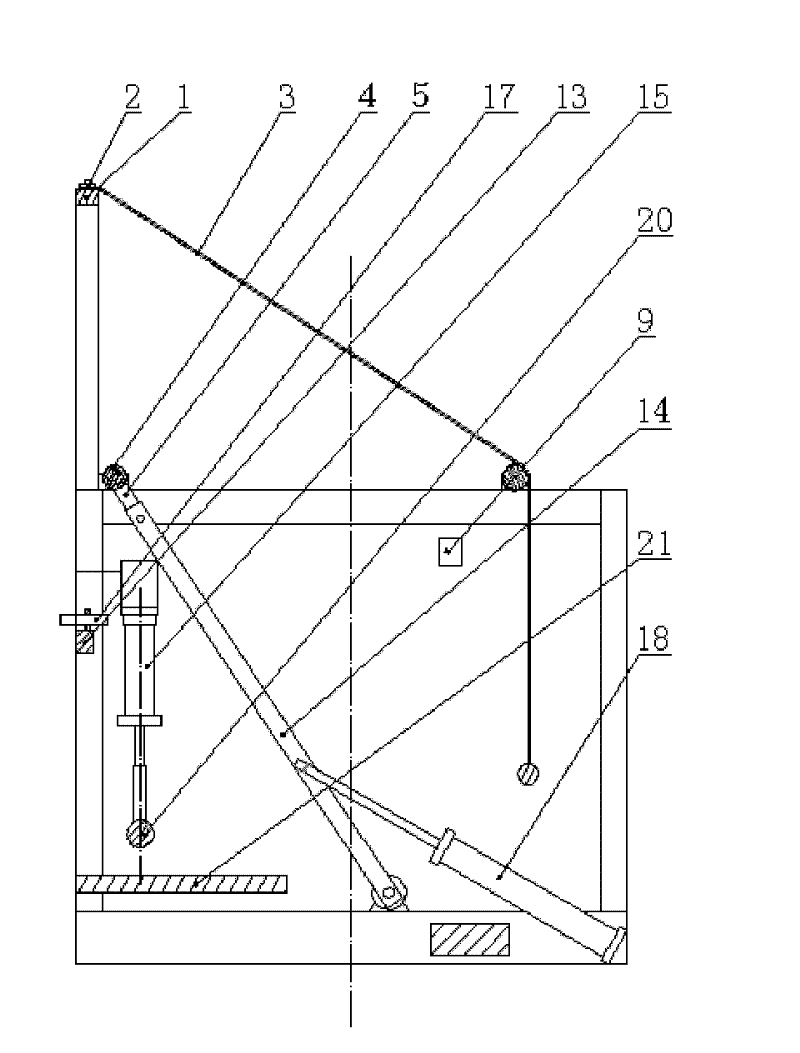

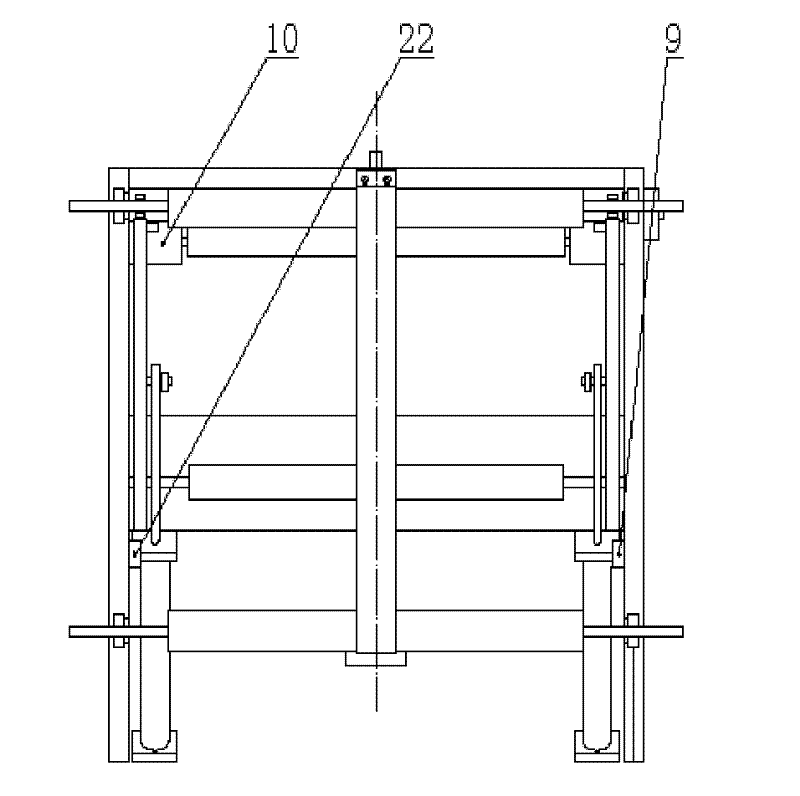

[0027] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

[0028] An automatic feeding device for a woven bag making machine, comprising a gate-shaped frame 16, a bracket 7, and an intermediate shaft 20. Described support is fixedly installed on the upper end surface of the two side walls of the portal frame, rollers 6 are installed on the side end surface of the support, and the intermediate shaft is installed on the bottom of the portal frame and adjacent to the feeding port of the woven bag making machine. Portal frame, support, and intermediate shaft are prior art, and are not repeated here.

[0029] The innovation point of the present invention is:

[0030] 1. The device also includes a detection mechanism, a transport mechanism and a crimping mechanism. Said:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com