Workpiece holding method

A workpiece and process technology, applied in the direction of manufacturing tools, instruments, manipulators, etc., can solve the problems of falling off the target workpiece and being unable to hold the target workpiece, and achieve the effect of improving the success rate of holding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, an embodiment of the present invention will be described based on the drawings.

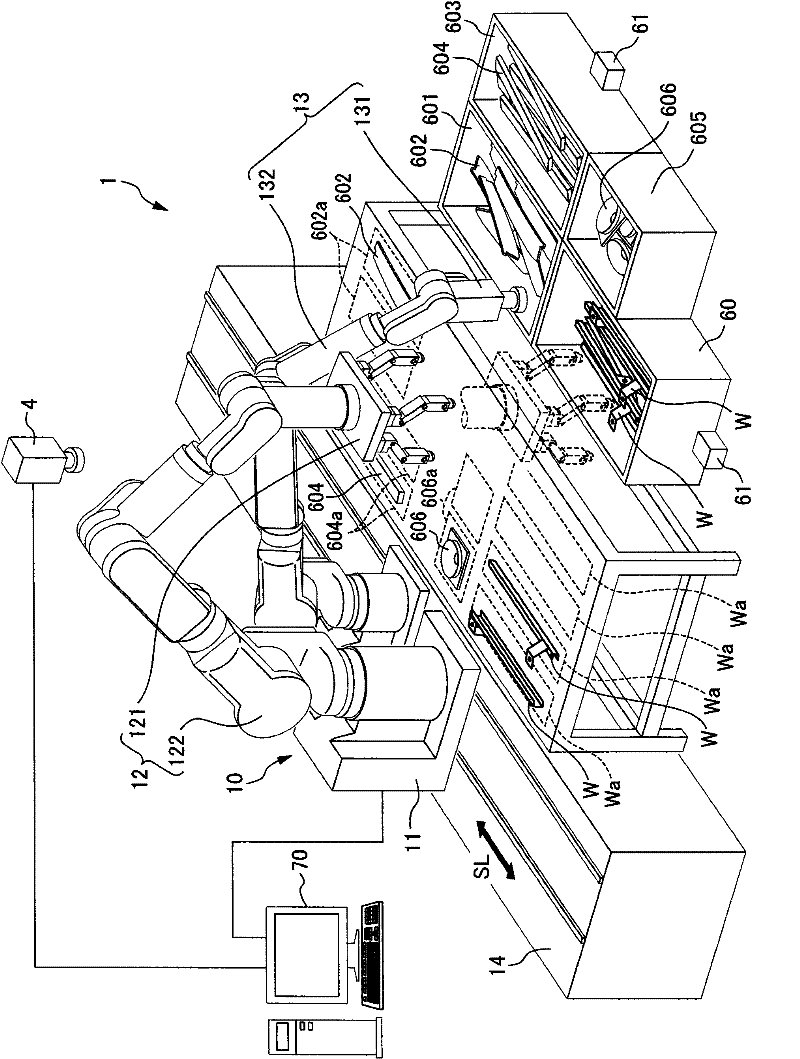

[0026] figure 1 It is a figure which shows the schematic structure of the workpiece placement system 1 which is a workpiece|work placement system used for the gripping method of the workpiece|work which concerns on one Embodiment of this invention.

[0027] The workpiece dispensing system 1 is installed on an auxiliary line that supplies a predetermined number of workpieces (assembled parts) to an assembly line for assembling automobiles in a state (equipped state) in which a predetermined number of workpieces (assembly parts) are arranged in advance at predetermined positions of a workpiece supply mechanism. Supply workpieces. The steel bar W as a workpiece in a state accommodated in the hopper 60 is supplied to the workpiece allocation system 1 . Also, the workpiece 602 accommodated in the hopper 601 , the workpiece 604 accommodated in the hopper 603 , and the workpiece 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com