Crane and movable-type balance weight mechanism thereof

A mobile and crane technology, applied in the direction of cranes, etc., can solve the problems of low operation efficiency of the whole vehicle, increase operator fatigue, etc., and achieve the effect of improving operation efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be pointed out that the description and sequence of specific structures in this section are only descriptions of specific embodiments, and should not be considered as limiting the protection scope of the present invention.

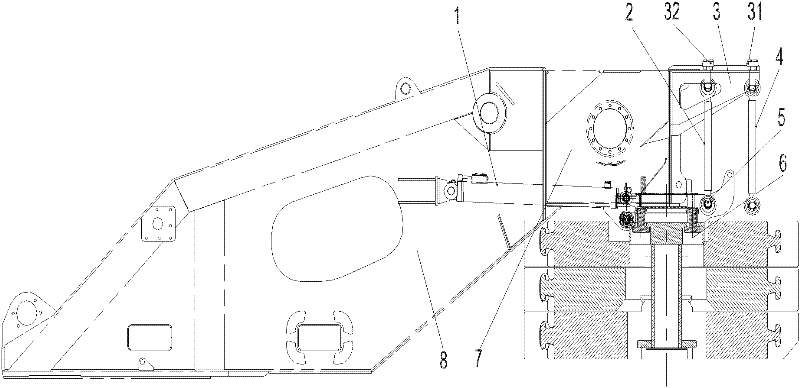

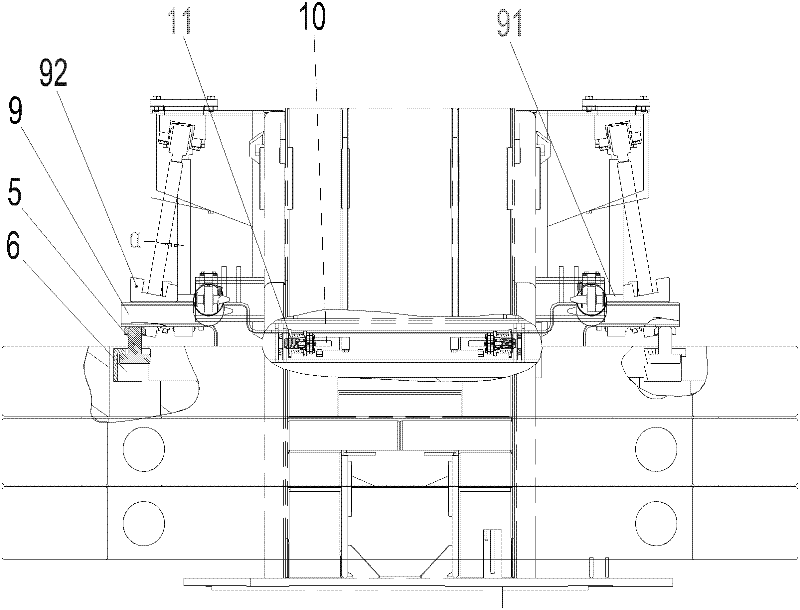

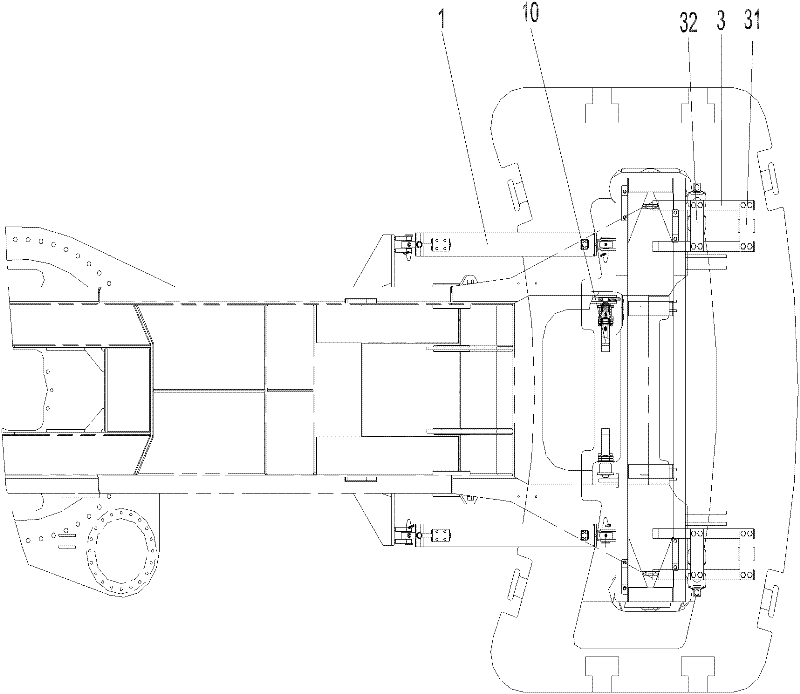

[0021] Combine the following at the same time Figure 1 to Figure 5 A mobile counterweight mechanism for a crane provided in the embodiment of the present invention will be described in detail.

[0022] As shown in the figure, the mobile counterweight mechanism includes a displacement cylinder 1, a pair of symmetrically arranged oblique rods 2, a symmetrically arranged pair of vertical rods 4, a connecting frame 9, a pair of bolt cylinders 10 and a pair of bolts 11, the connection relationship...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com