Automatic lifting structure for lens of motorcycle helmet

A technology for motorcycles and lenses, applied in helmets, helmet covers, clothing, etc., can solve problems such as inconvenience in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

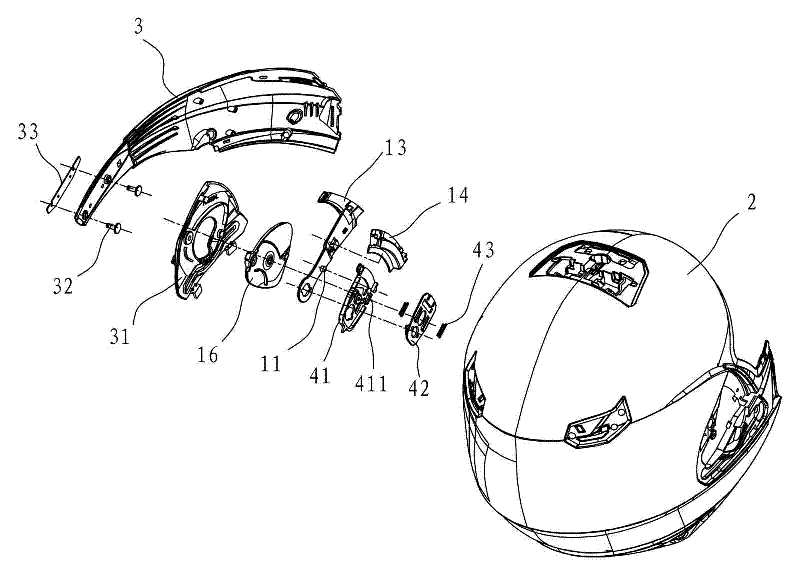

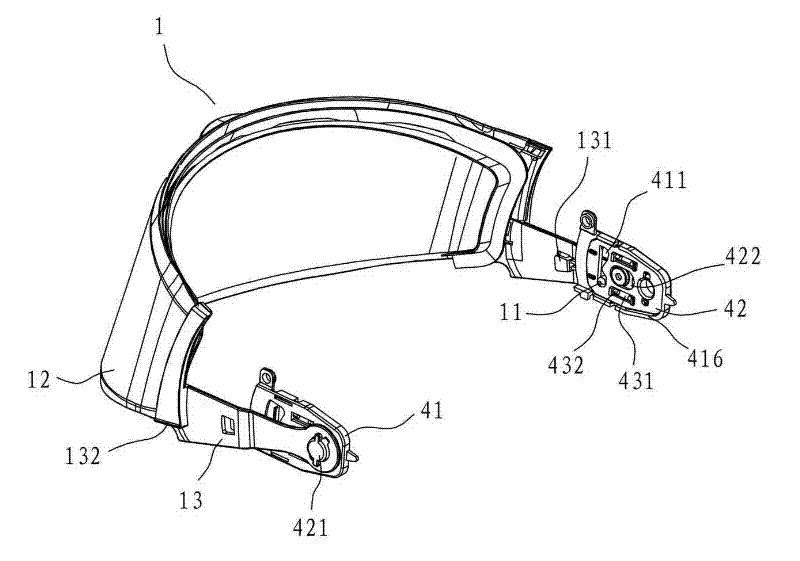

[0022] Such as figure 1 As shown, the present invention proposes a motorcycle helmet lens automatic lifting structure, which is used to movably install the lens of the motorcycle helmet on the motorcycle helmet, so that the lens not only has the function of opening and closing, but also makes the lens open when it is opened. Turns on a preset track to match the helmet's jaw guard.

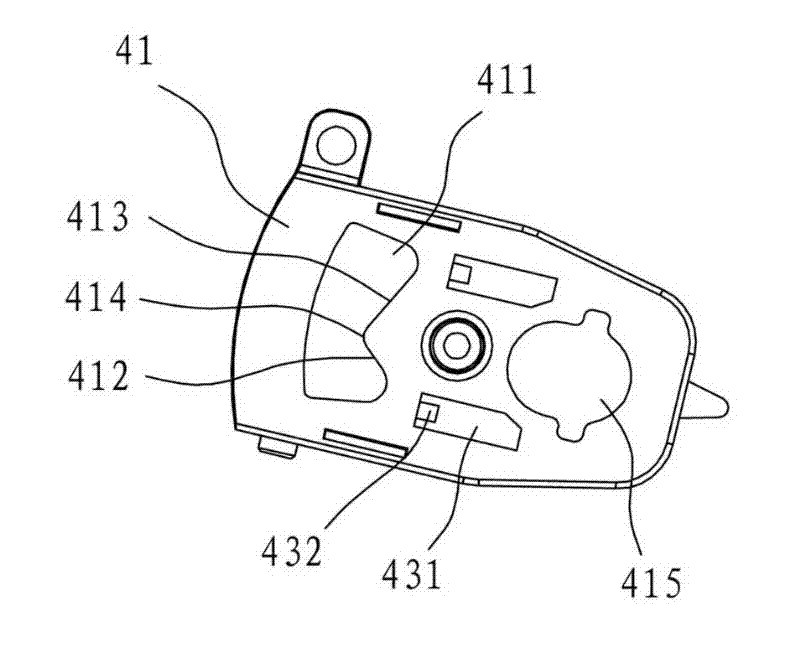

[0023] Such as figure 1 , 2 , 3 and 4, the main body of the automatic lifting structure is a base assembly that movably connects the lens 1 to the helmet main body 2 and makes the lens 1 rotate according to a certain track. The base assembly includes an upper base 41 and a lower base 42, Wherein the upper base 41 can be fixed on the helmet main body 2 through a locking structure or screws, and the lower base 42 is movably clamped between the upper base 41 and the helmet main body 2 and is hinged with the lens 1, so that the outermost lens 1 can not only be opposite The helmet main body 2 rotates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com