Tunneling and drilling all-in-one machine

An integrated machine and drilling rig technology, applied in the field of mining machinery, can solve the problems of inconvenient installation and disassembly process of roadheaders and drilling rigs, limited scope of application, inflexible movement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

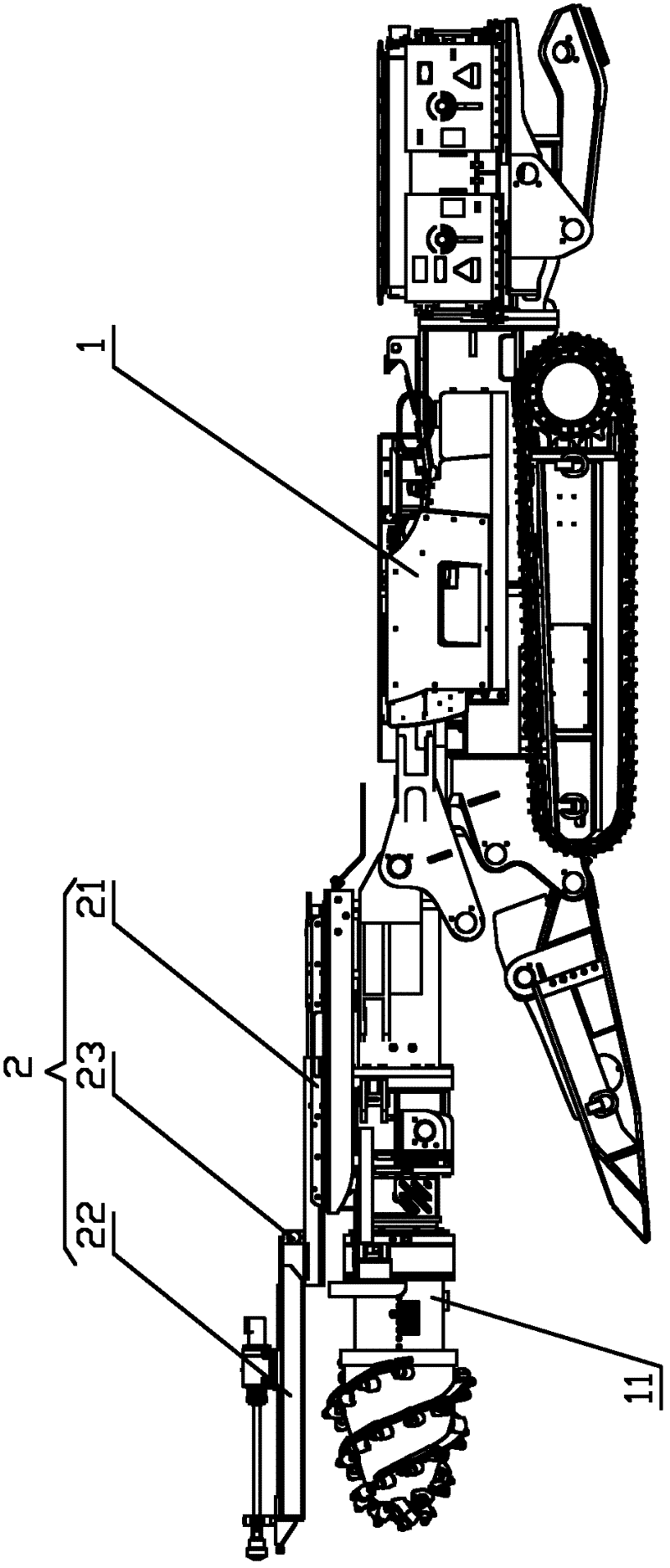

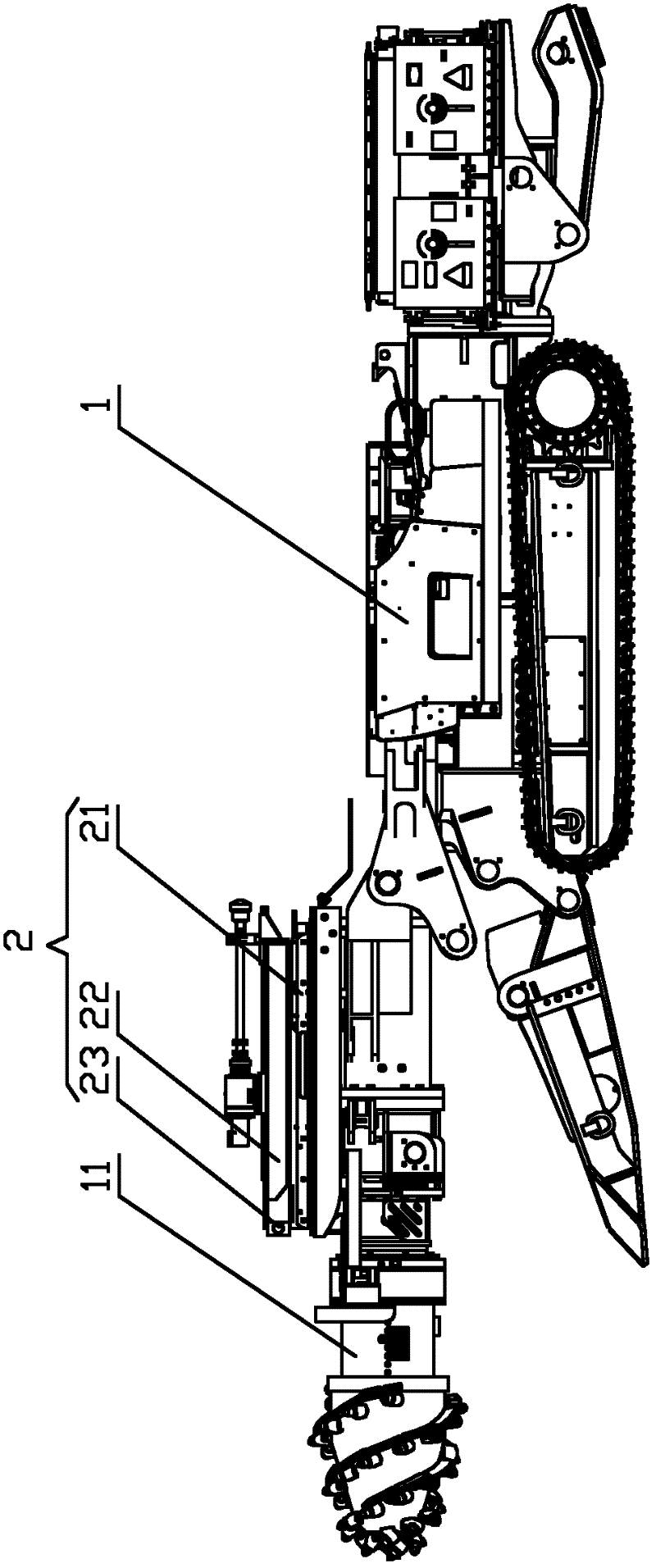

[0026] The core of the present invention is to provide a kind of excavating and drilling integrated machine, its drilling machine 2 moves flexibly relative to the roadheader 1, and the structure of the drilling machine 2 is simple, the layout is reasonable, and the space occupied above the cutting arm of the roadheader 1 is small, The installation and removal process is simple and convenient.

[0027] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] Please refer to figure 2 with image 3 , figure 2 It is a structural schematic diagram of a specific embodiment of the all-in-one digging and drilling machine provided by the present invention; image 3 for figure 2 Schematic diagram of the structure of the middle drilling machine 2 when it is in the withdrawn state. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com