Multilayer circuit board and assembly thereof

A multi-layer circuit board and circuit board technology, which is applied to printed circuits, printed circuit components, electrical components, etc., can solve the problems of ambiguous marking codes, unrecognizable reversed front and back, and inability to detect multi-layer circuit boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

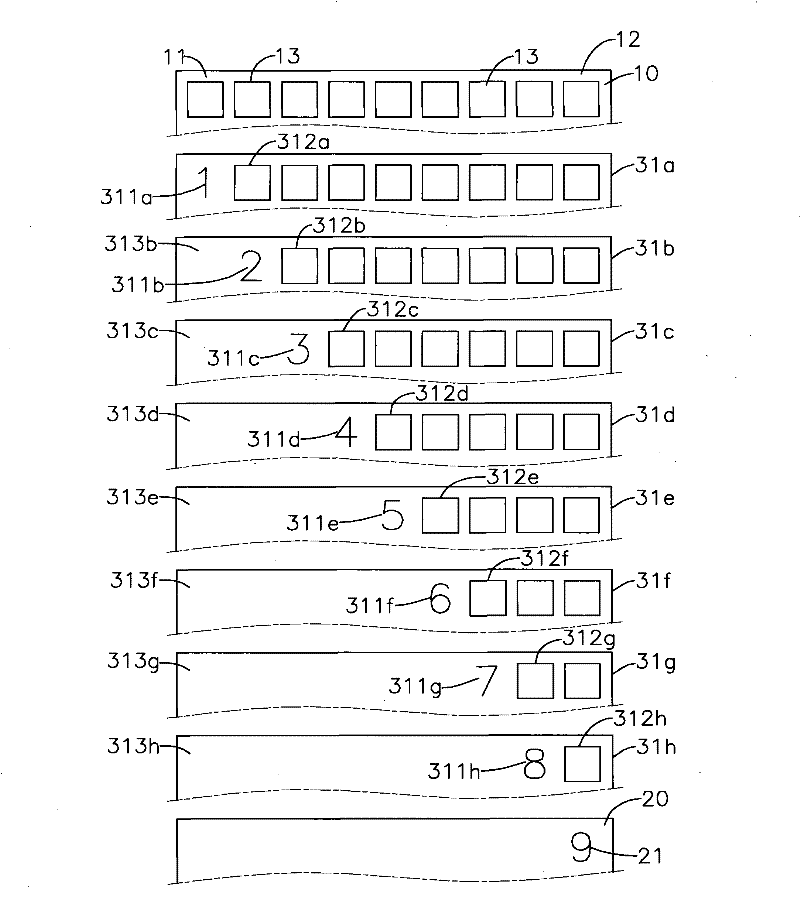

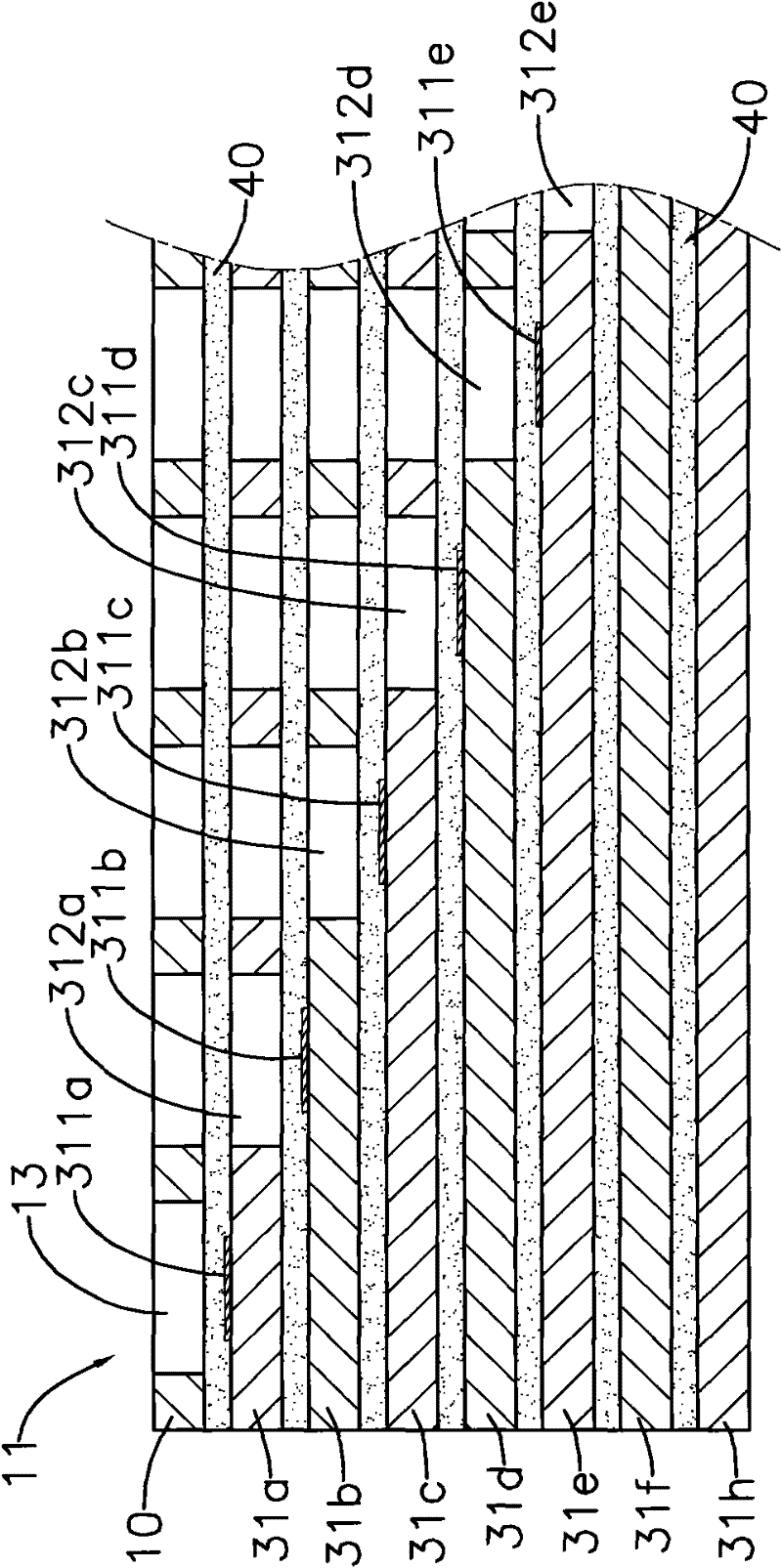

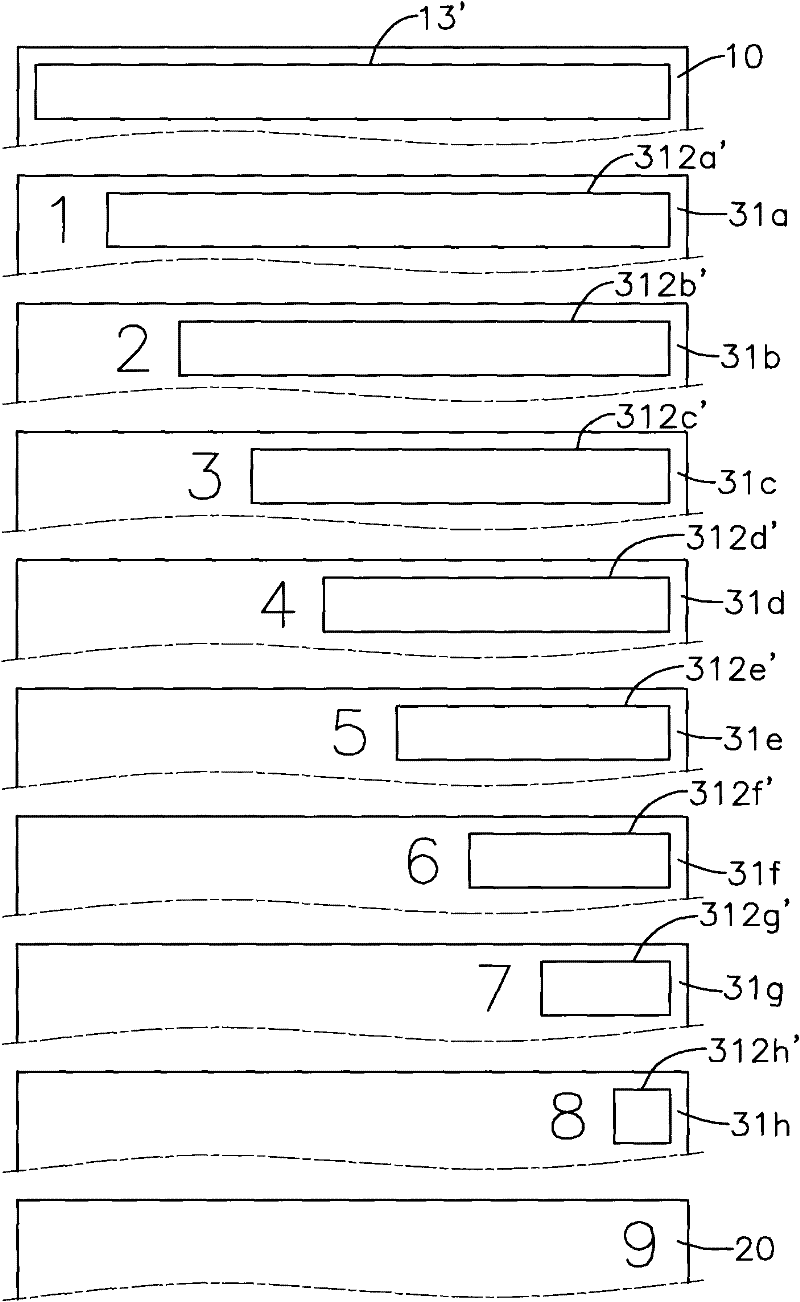

[0034] Please see figure 1 , figure 2 As shown, it is a multilayer circuit board of the first embodiment of the present invention, which includes:

[0035] A top outer layer circuit board (10), which is provided with n openings (13) at intervals from a first position (11) to an nth position (12) near an edge, where n is an integer greater than 2;

[0036] a bottom outer circuit board (20) forming an nth identification code (21) at an nth position (12) relative to the top outer layer circuit board (10);

[0037] a plurality of central circuit boards (31a-h) having n-1 central circuit boards (31a-h) from the top outer circuit board (10) towards the bottom outer circuit board (20), wherein the first central The circuit board (31a) is formed with a first identification code (311a) relative to the first position (11) of the top outer layer circuit board (10), and is spaced from the second position to the nth position (12) A plurality of first through holes (312a) are provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com