Ink box used for ink-jet printer

An inkjet printer, printer technology, applied in printing and other directions, can solve problems such as installation detection errors, and achieve the effect of improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

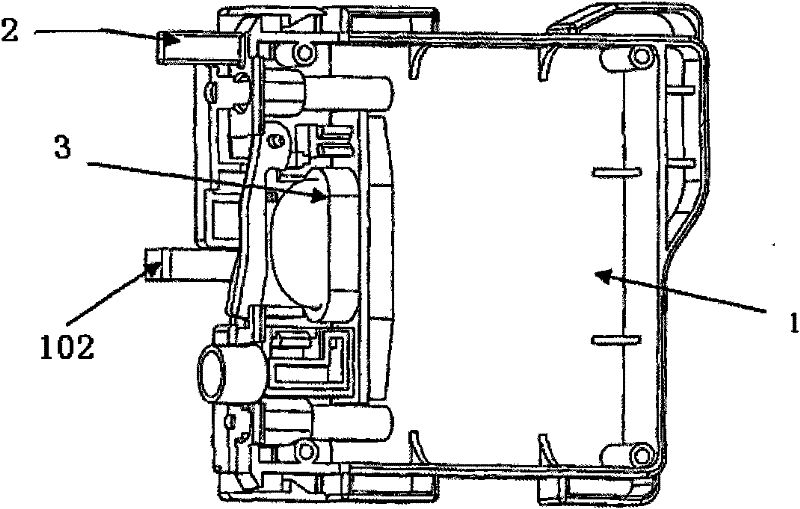

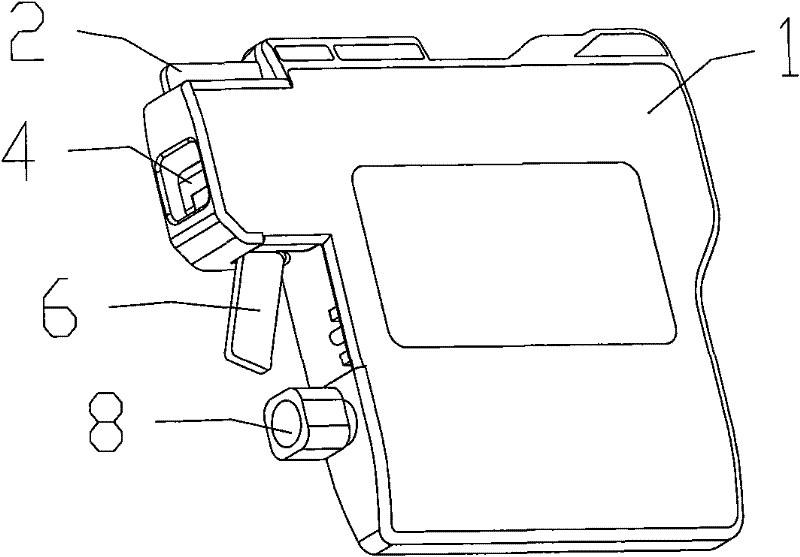

[0034] Such as figure 2 As shown, the ink cartridge 1 of the embodiment of the present invention includes: an ink storage cavity 11 ( Figure 7 (Shown), the installation detection mechanism-the first detection component 2 and the movable lever member 6, the ink volume detection mechanism-the movable lever member 6 and the lever assembly 9 ( Figure 7 Shown), ink outlet 8, eject mechanism-reset component 4.

[0035] Wherein, a certain amount of ink is stored in the ink storage cavity 11, and at least one outer wall is composed of a variable film. And through the ink outlet 8 to provide ink to the printer.

[0036] The installation detection mechanism includes a first detection component 2 and a second detection component. The second detection component includes a movable lever 6 and a shaft 7.

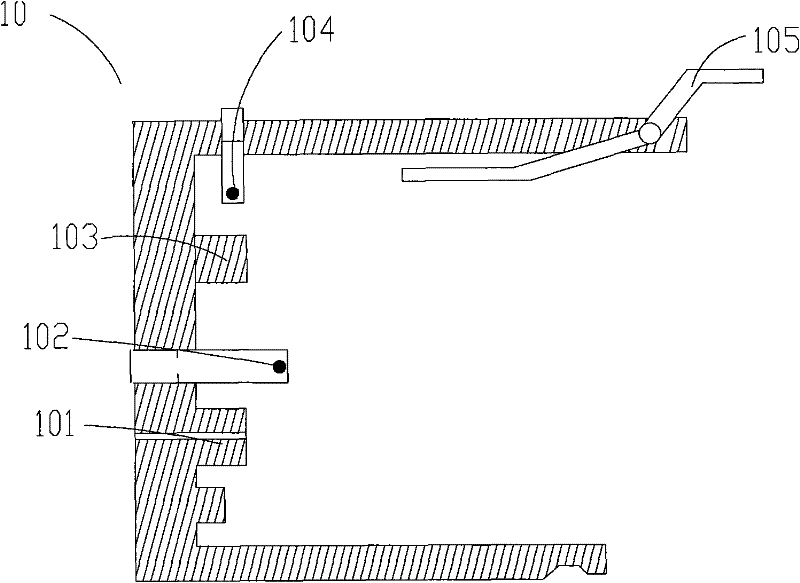

[0037] During the installation of the ink cartridge, the second signal blocking area 61 of the movable lever 6 blocks the second signal sent by the second sensor 102 for the first time. Imme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com