Method and system for controlling power matching of mobile working machine

A technology of mobile operation and control method, which is applied in the direction of fluid pressure actuation system components, mechanical equipment, fluid pressure actuation devices, etc., and can solve problems such as different pressure loss and hydraulic pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

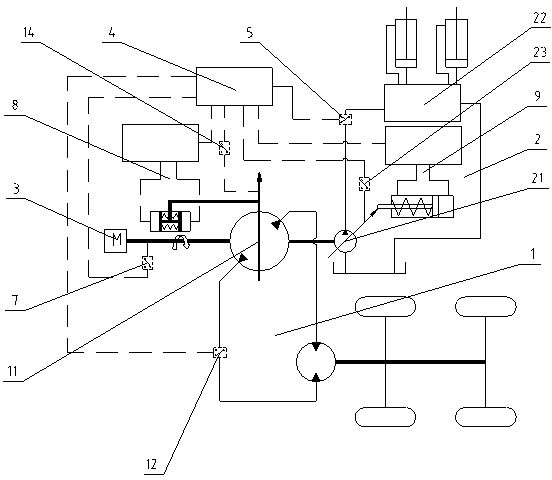

[0020] Embodiment 1: as figure 1 As shown, the power distribution control system of the mobile working machine includes a traveling hydraulic system 1, a working hydraulic system 2 and an engine system 3. The traveling hydraulic system 1 includes a traveling pump 11, and the working hydraulic system 2 includes a working pump 21. The traveling pump 11 And the working pump 21 is connected with the engine system 3 , therefore, the traveling pump 11 and the working pump 21 are kept in linkage with the engine system 3 . The power distribution control system also includes pressure sensors 5, 12 for measuring the pressure of the working hydraulic system 2 and the traveling hydraulic system 1, a speed sensor 7 for measuring the engine speed, detecting the working pump 21 of the working hydraulic system 2 and the traveling pump 11 of the traveling hydraulic system 1 Displacement sensors 23, 14 of the displacement, a controller 4 that receives the signals of the displacement sensors 23,...

Embodiment 2

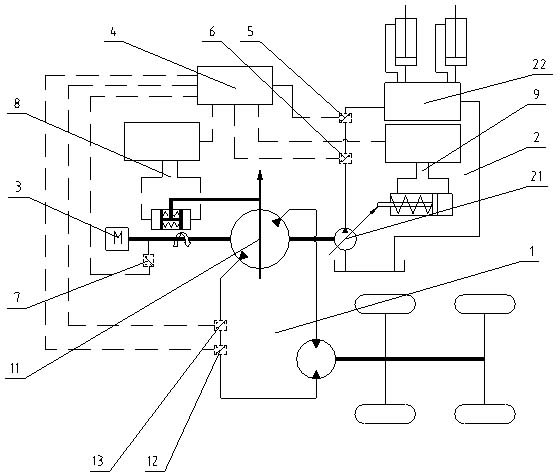

[0025] Embodiment 2: as figure 2 As shown, the power distribution control system of the mobile working machine includes a traveling hydraulic system 1, a working hydraulic system 2 and an engine system 3. The traveling hydraulic system 1 includes a traveling pump 11, and the working hydraulic system 2 includes a working pump 21. The traveling pump 11 And the working pump 21 is connected with the engine system 3 , therefore, the traveling pump 11 and the working pump 21 are kept in linkage with the engine system 3 . The power distribution control system also includes flow sensors 6 and 13 for measuring the flow of the working hydraulic system 2 and the traveling hydraulic system 1, pressure sensors 5 and 12 for measuring the pressure of the working hydraulic system 2 and the traveling hydraulic system 1, and a speed sensor for measuring the engine speed 7. The controller 4 that receives the signals of the flow sensors 6, 13, the pressure sensors 5, 12 and the speed sensor 7, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com