Sandwich insulation structural panel and manufacturing method thereof

A technology of thermal insulation structure and manufacturing method, which is applied in the direction of building structure, chemical instruments and methods, and on-site preparation of building components, which can solve the problems of not being able to make full use of formwork performance, increasing man-hour consumption and material loss, and rising costs. Achieve the effect of shortening the construction period, ensuring the construction quality and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

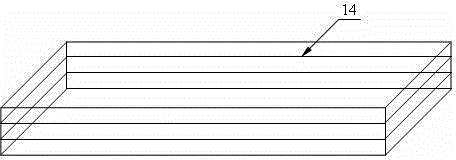

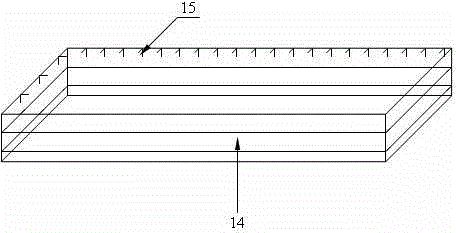

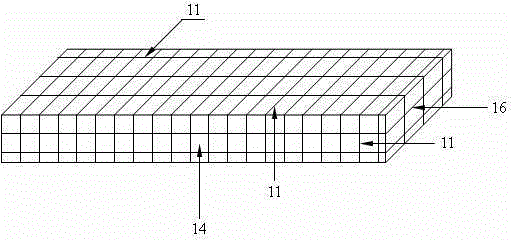

[0028] A sandwich thermal insulation structural panel, consisting of at least two structural panel units 1, the structural panel unit 1 is as Figure 1 to Figure 5 As shown, it is composed of fiber 11, organic resin 12, thermal insulation material 13 and support frame 14, and support frame 14 is as figure 1 As shown, it is a prismatic or pyramid-shaped frame, such as figure 2 Shown, each limit of supporting framework 14 is all provided with hook 15, as image 3 As shown, the fibers 11 are respectively connected to the hooks 15 on the same facing side in the support frame 14, and the hooks 15 on opposite sides of the support frame 14, as Figure 4 with Figure 5 As shown, the organic resin 12 permeates the inside of the fiber 11 and is wrapped on the outer surface of the fiber 11, the heat insulating material 13 is in a porous state, and the heat insulating material 13 is assembled or filled in the gap between the fibers 11 impregnated with the organic resin 12 and will The...

Embodiment 2

[0046] A sandwich thermal insulation structural panel is composed of at least two structural panel units 1, and its manufacture includes preparation of fabric net panels, cleaning of fibers, impregnation of organic resins, formation of organic resin solidified grids and sealing of the periphery.

[0047] When preparing the fabric net plate, the two openings of the support frame 14 form two parallel planes, the two parallel planes are respectively the bottom surface and the top surface, and the hook 15 of the support frame 14 is fixed on the hook 15 made of fiber net or fiber cloth. The mesh, the mesh is parallel to the bottom surface and the top surface, and the layers of mesh from the bottom to the top surface are the bottom mesh, the first layer of mesh, the second layer of mesh to the top mesh, the bottom mesh and the second mesh. Between one layer of mesh, fibers 11 are wound around the hooks 15 at both ends to form a connecting line, and fibers 11 are woven into a three-di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com