Workpiece trolley of drying oven

A technology for carts and workpieces, which is applied in the field of workpiece carts in ovens, which can solve the problems of reduced production efficiency, inability to roll, and inability to use lubricating oil, so as to avoid production stagnation and reduce friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

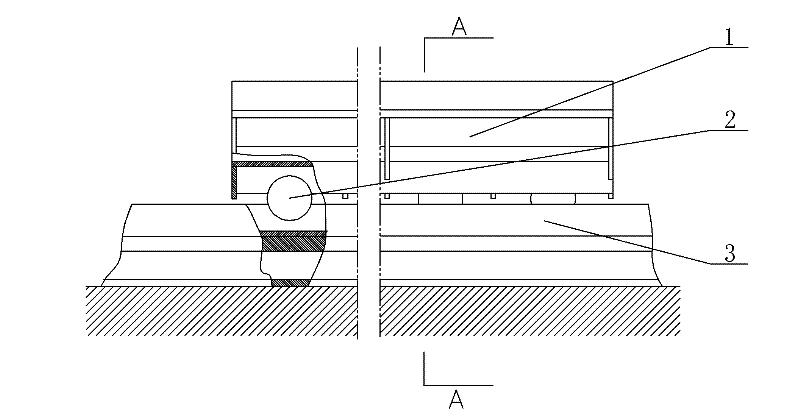

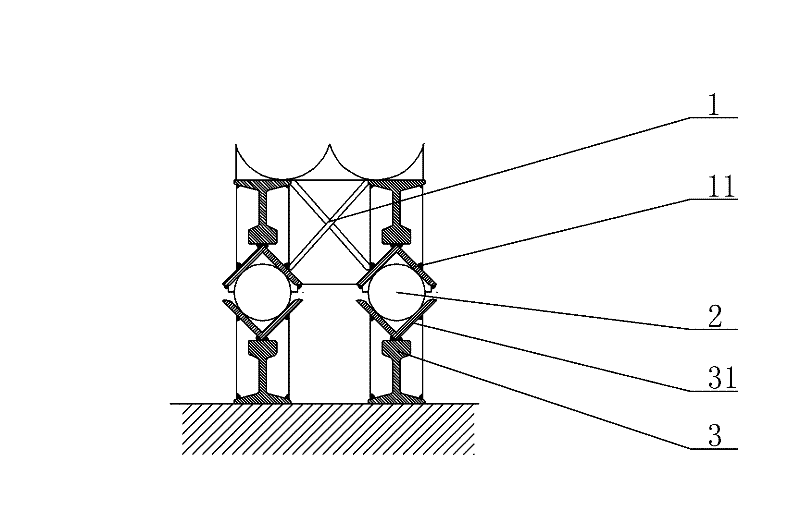

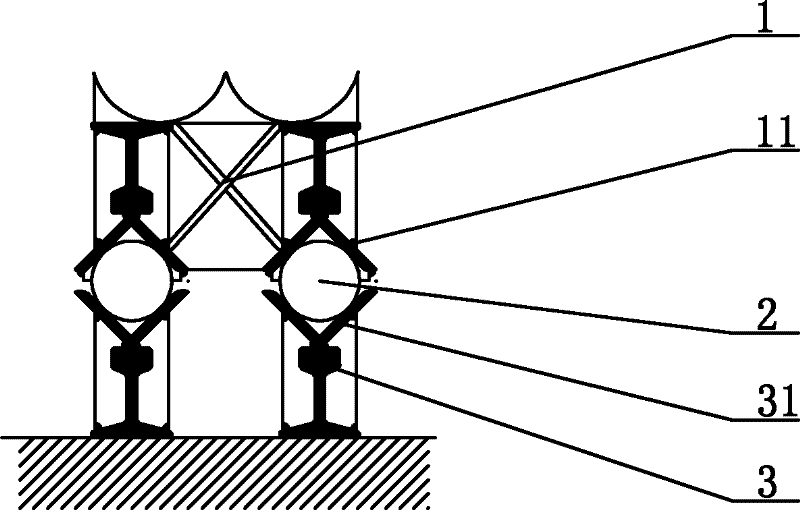

[0008] Below in conjunction with accompanying drawing, the preferred embodiment of the workpiece trolley of a kind of oven case of the present invention is described in detail:

[0009] Such as figure 1 with figure 2 As shown, the workpiece trolley of this oven is mainly composed of a track 3 and a workpiece trolley 1 moving back and forth on the track 3; the track 3 is two parallel rails, the top of each rail is V-shaped, and the V-shaped opening Upwards, form track notch 31, and several steel balls 2 are built-in in V-shaped track notch 31; It is V-shaped, with the V-shaped opening facing downwards. Two trolley notches 11 are arranged in parallel, and their parallel spacing is equal to that of the track 3. The trolley notch 11 is buckled on the upper part of the ball 2, and the ball 2 and the track notch 31 Two-point contact is maintained, and the ball 2 also maintains two-point contact with the notch 11 of the cart, so that the workpiece cart 1 and the track 3 are slidab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com