Rapid wall plastering equipment

A technology for powder walls and equipment, which is applied in the direction of construction and building construction, can solve the problems of mortar falling, time-consuming, laborious and wasteful, and achieve the effects of not easy falling, simple structural parts and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

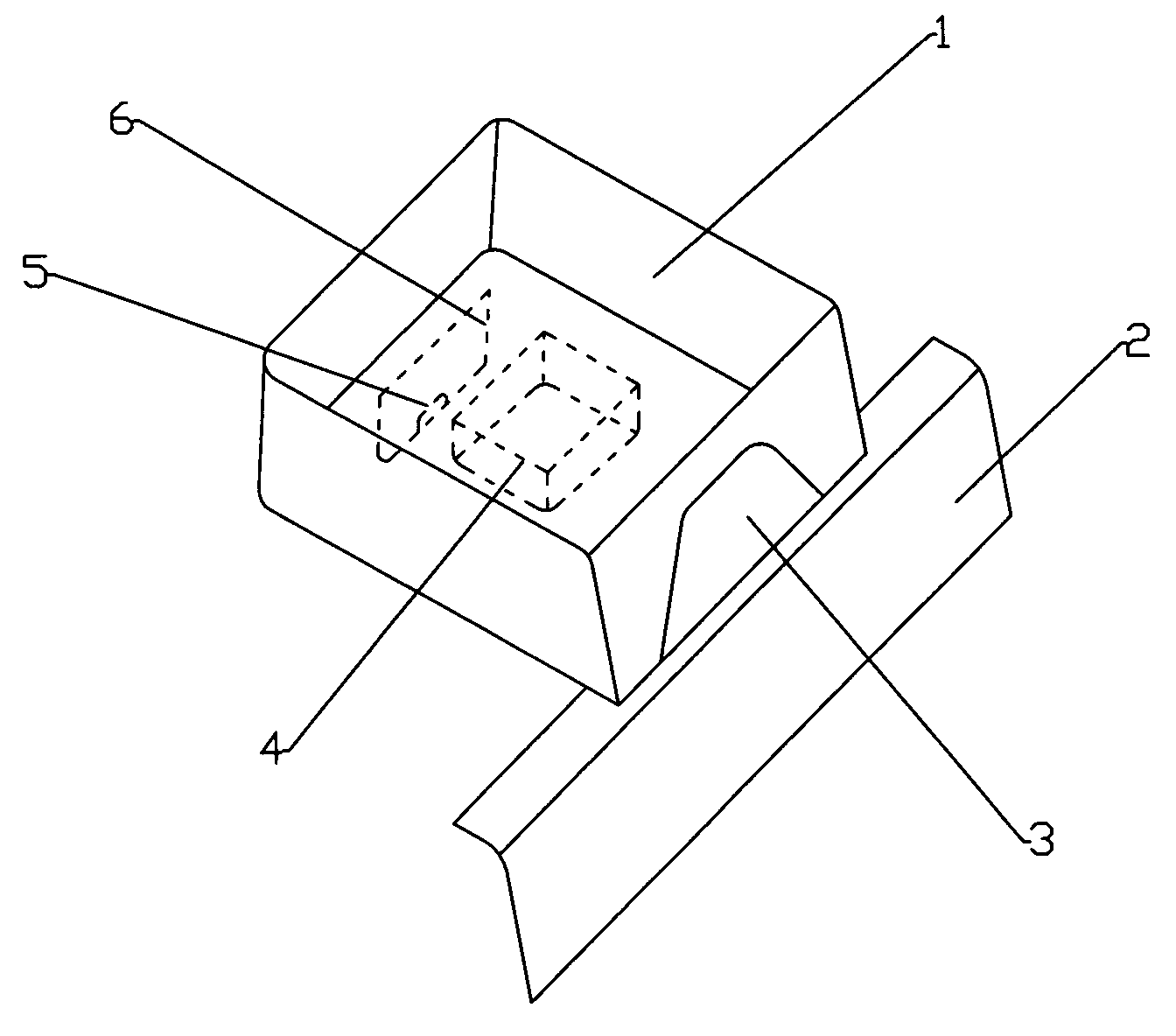

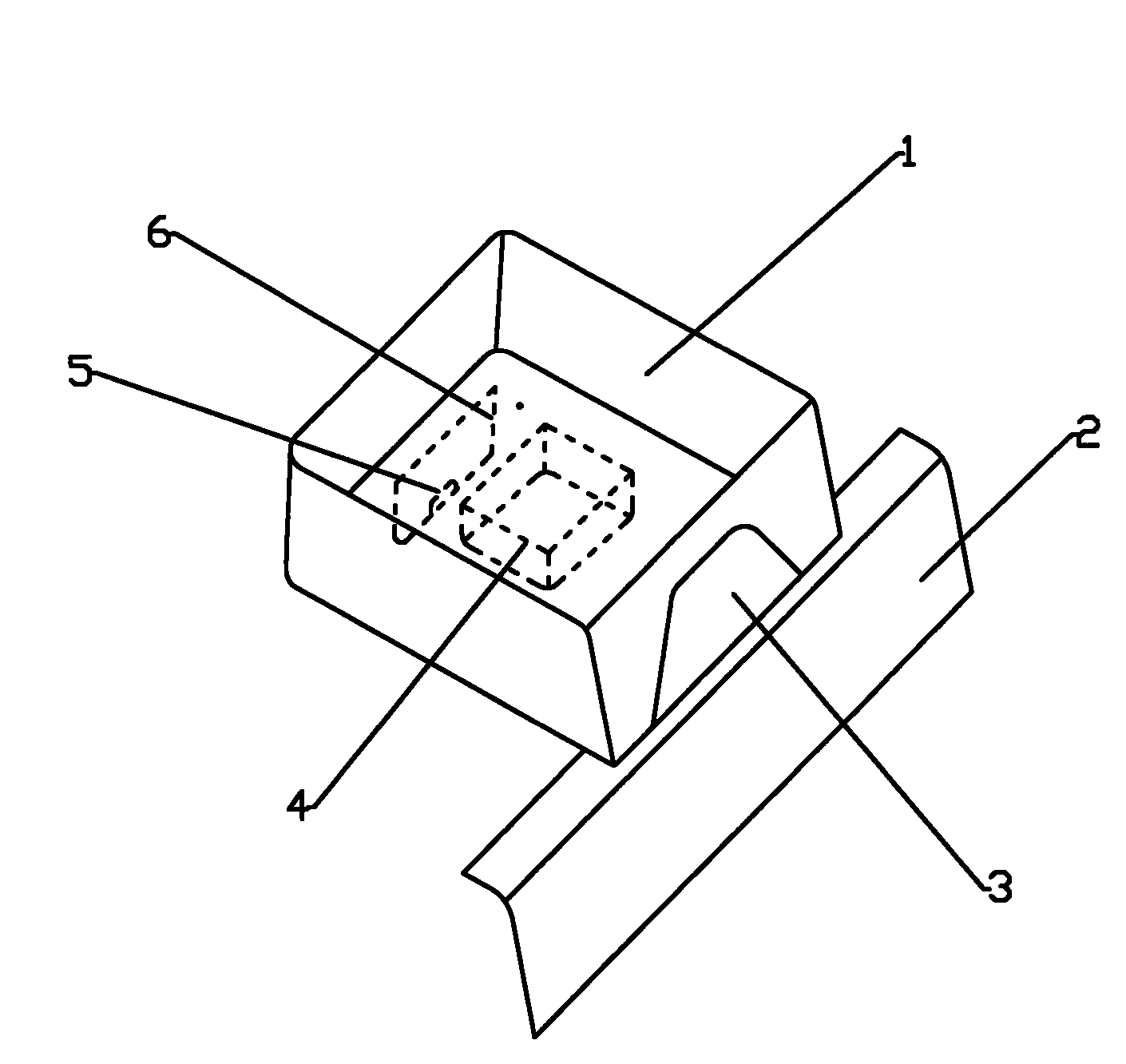

[0008] Embodiment 1: including the powder wall equipment, the bottom surface of the feeding frame 1 is connected to the bottom surface of the feeding frame 1 by the feeding frame 1, the formwork 2, the feeding port 3, the vibrator 4, and the formwork 2. , The side of the feeding frame 1 has a feeding port 3, the bottom surface of the feeding frame 1 is equipped with a vibrator 4 and a handle 6, and the handle 6 is provided with a power switch 5.

[0009] The powder wall surface of the formwork 2 protrudes from the surface of the feeding port 3 or remains in the same plane as the surface of the feeding port 3

[0010] When in use, put the mortar into the feeding frame, turn on the power switch 5, hold the handle, and the template 2 is close to the wall. With the vibration of the vibrator 4, the mortar continuously flows out from the feeding port 3, and the template 2 also vibrates , and tamp the outflowing mortar onto the wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com