Detaching device for screw rod and threaded element of extruder

A threaded element and removal device technology, which is applied in the field of extruder screw threaded element removal device, can solve the problems of difficult disassembly of threaded blocks, high cost, time-consuming and labor-intensive heating of threaded blocks, etc., to protect process performance and prolong service life , the effect of saving casting cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

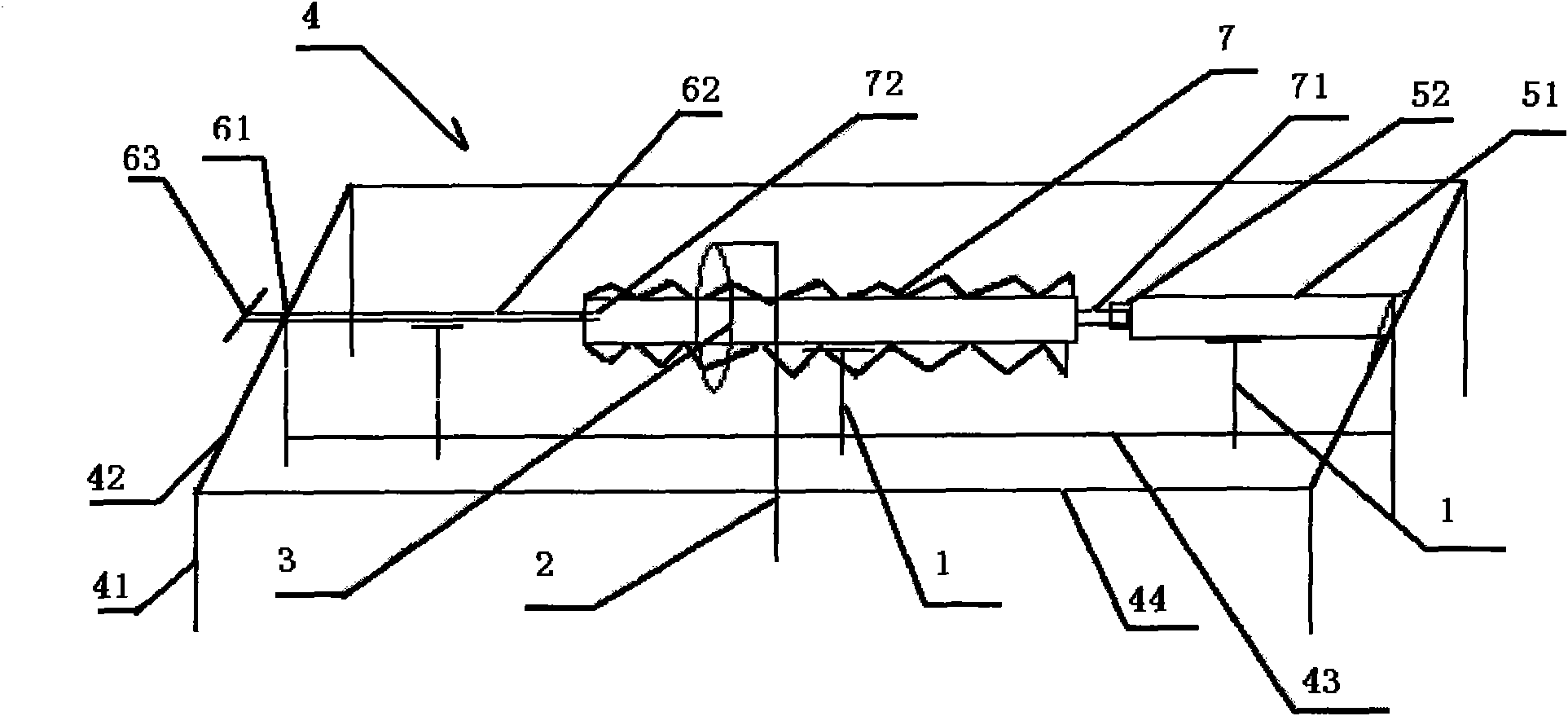

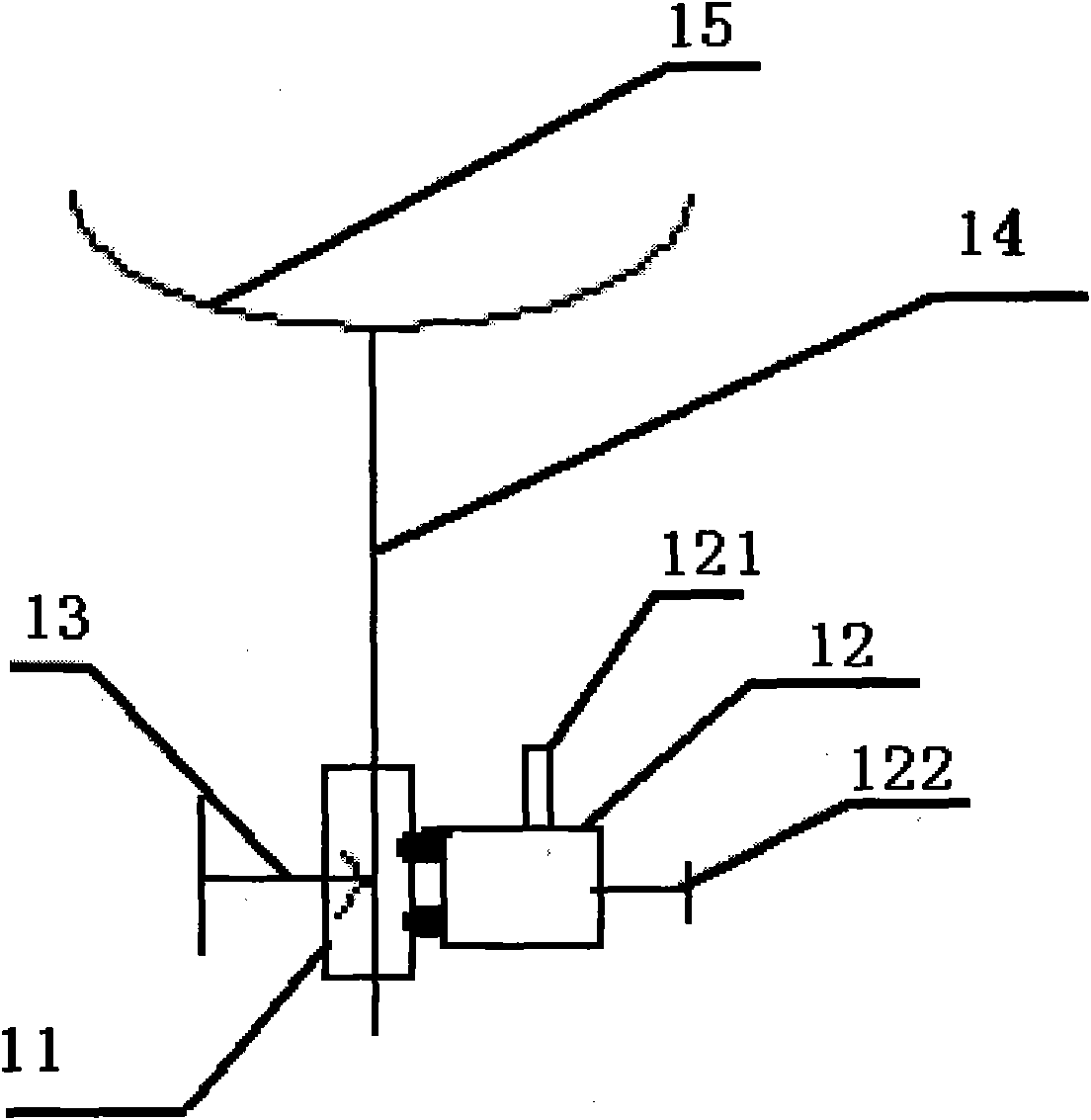

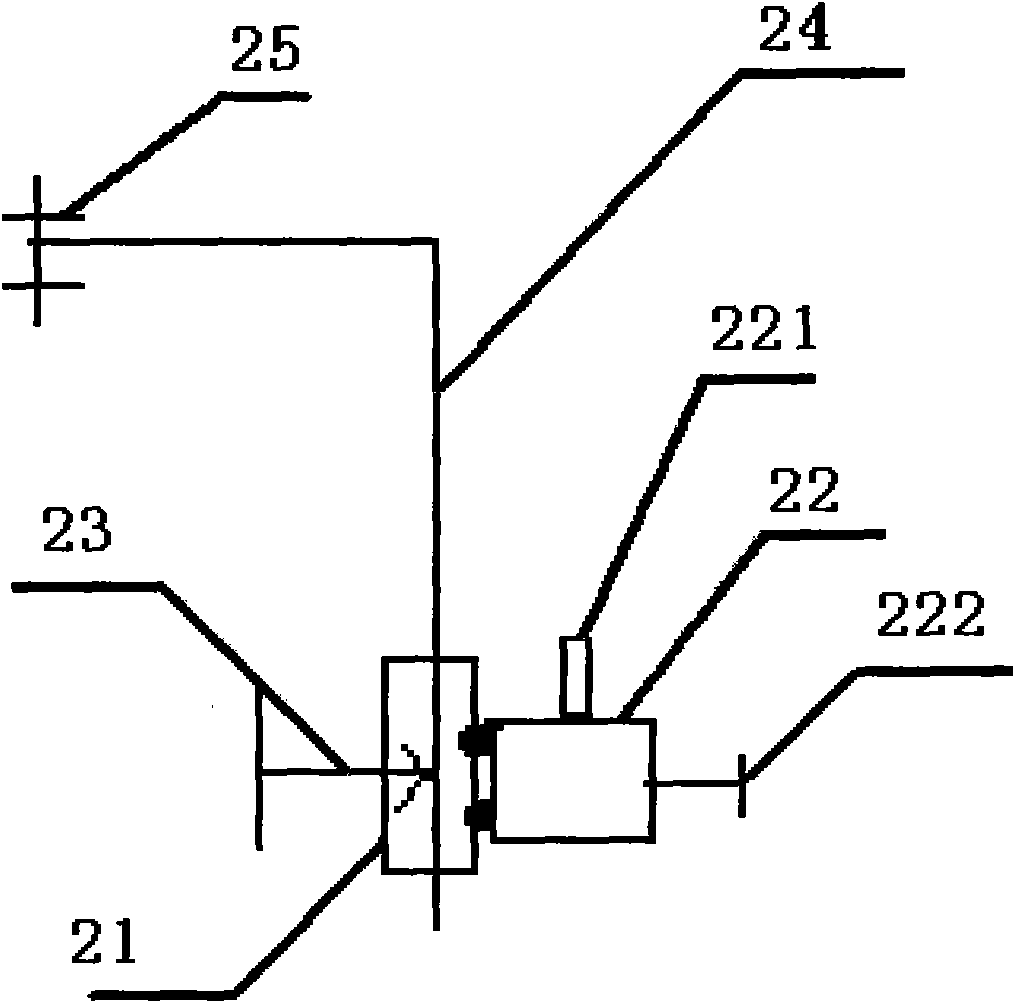

[0032] The specific embodiment of extruder screw thread element removal device of the present invention, as figure 1 As shown, the device includes a body support part 4, a screw sliding support part 1, a heating ring sliding support part 2, a screw mandrel spline ferrule part and a tightening screw part arranged on the integral support part 4, and a Homogenized temperature heating ring part 3 on heating ring slide bracket part 2.

[0033] The body bracket part 4 is made of a metal square tube, which includes a plurality of legs 41 , and a body bracket 42 , a screw slide rail 43 and a heating ring slide rail 44 erected on the legs 41 . Six supporting legs 41 are vertically arranged, wherein three supporting legs 41 form a group, and the three supporting legs 41 are arranged in a straight line, and the other three supporting legs 41 also form another grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com