Method, fabrics and machines for producing seamless bags and similar items

A bag and fabric technology, applied in the direction of envelope/bag manufacturing machinery, fabrics, bags, etc., can solve the problems of high cost and not very strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

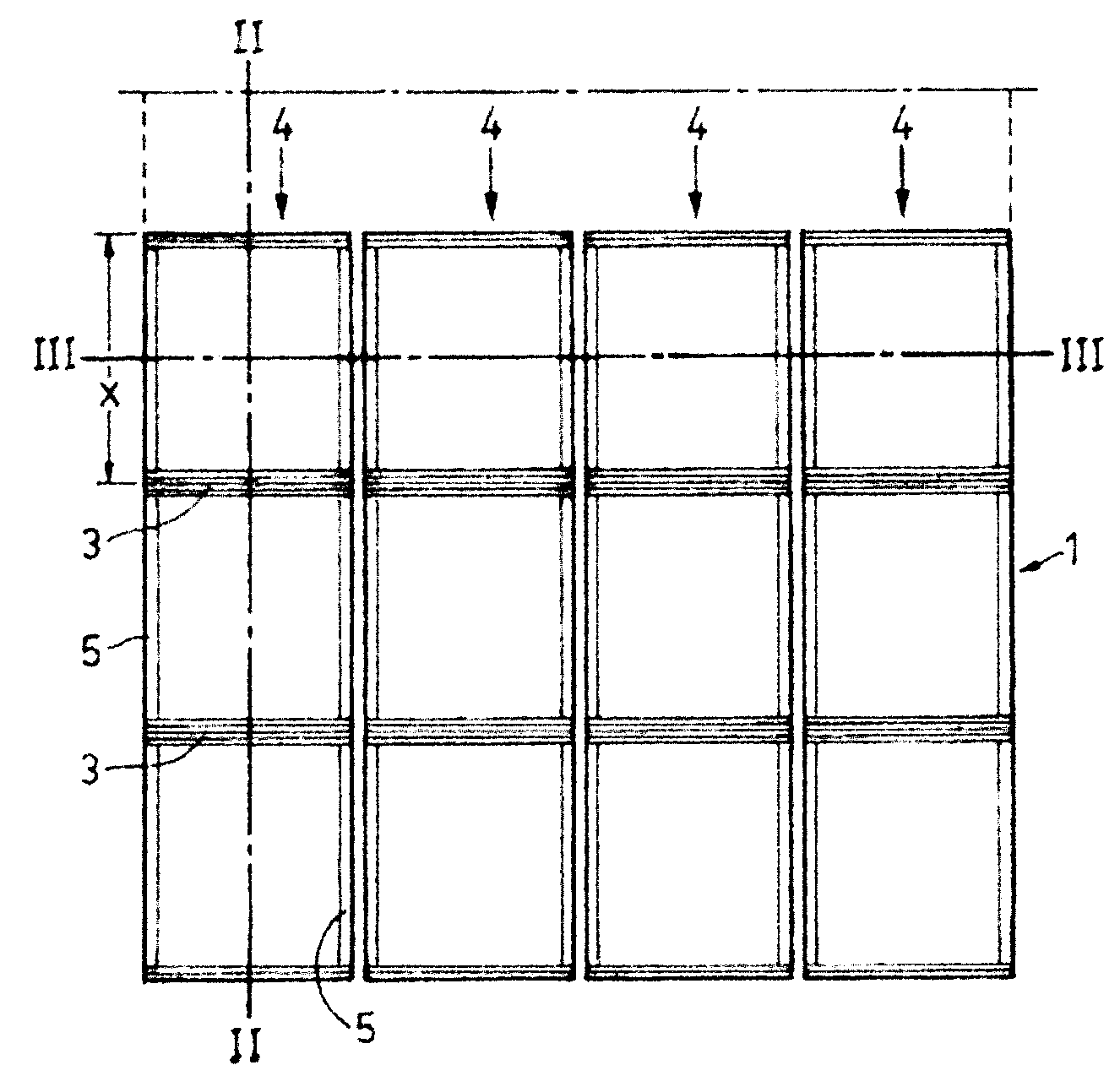

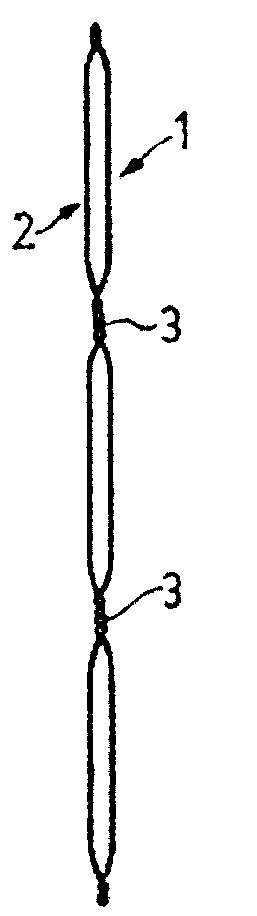

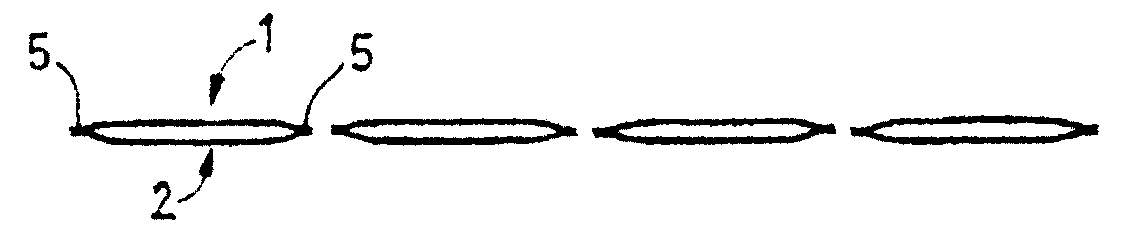

[0032] According to the accompanying drawings, the object of the method of the invention for obtaining seamless bags and similar products made of fabric consists in weaving two Separate superimposed cloths 1 and 2 are joined laterally at a predetermined distance x by interweaving warp strands with weft strands 3 .

[0033] Simultaneously, the individual warp tapes 4 are formed in the loom so that the longitudinal edges of these tapes are terminated with corresponding selvedges 5 .

[0034] These bands 4 are subjected to transverse die-cutting 6 ( Figure 4 ), thereby forming a bag 7 with an opening 8, for example, using a rotating cylinder or a "flat knife" ( Figure 5 ).

[0035] exist Figure 7 In the case of , a transverse die-cut 6' is performed in the area where the two cloths are joined by the weft strand 3, and this is supplemented by other curved cuts 9, 10 and 11 forming the handles 12 and 13 of the bag 7'.

[0036] Figure 11 The strip is shown already cut, but ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com