Inspection device

A technology for inspecting devices and objects, applied to measuring devices, material analysis through optical means, instruments, etc., can solve the problems of not being able to recognize images well, recognize them as images, and check standard deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

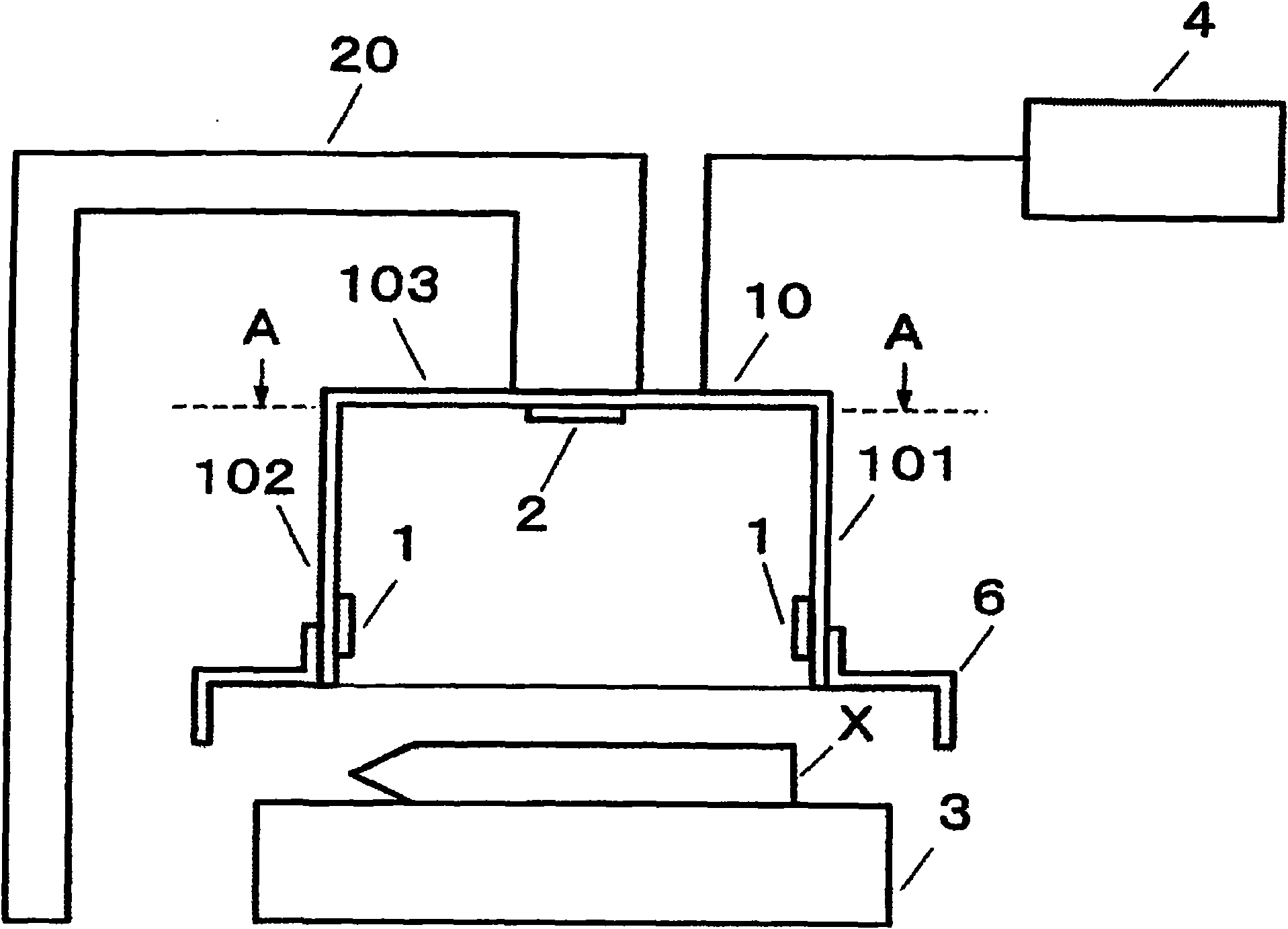

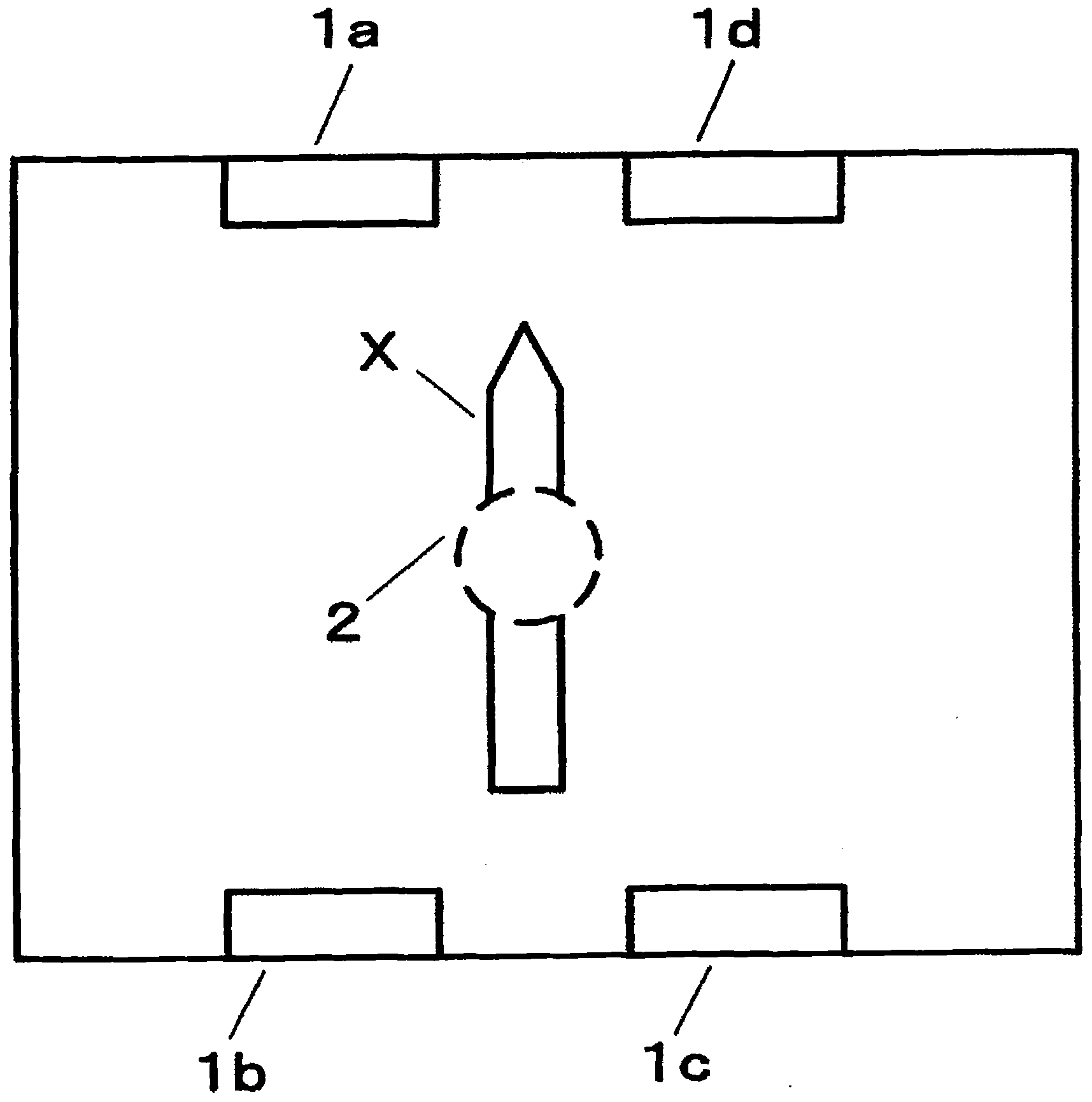

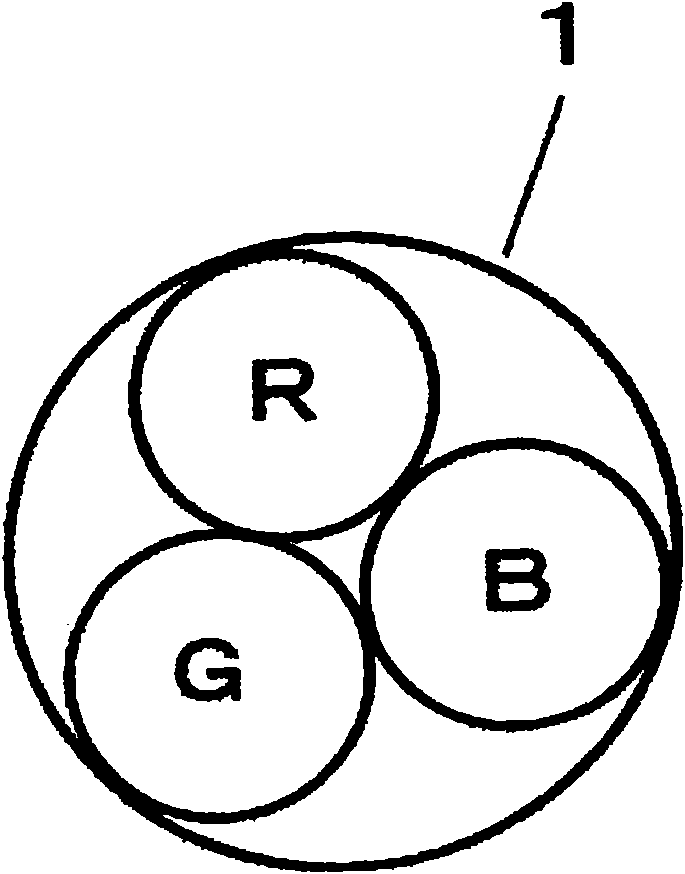

[0018] figure 1 An example of the inspection device according to the present invention is shown, and a schematic configuration of an inspection device for a cap of a plastic colored ballpoint pen is shown. figure 2 show from figure 1 Arrow A observes the state diagram below. The illuminating tube 10 having a box shape as a whole is held by a pillar 20 . On the inner surface of the side wall 101 and the inner surface of the side wall 102 of the lighting tube 10, LED 1 (1a, 1b, 1c, 1d) as a lighting unit is attached. In addition, a camera 2 (UL-1460SE-C-GL type manufactured by Imaging Development System (IMAGE DEVELOPMENT SYSTEM) Co., Ltd.) as an image recognition unit is mounted on the inner surface of the upper wall 103 of the lighting tube 10 . The lower side facing the upper wall 103 is open, and a table 3 for holding and fixing a cap X of a plastic colored ballpoint pen as an object is provided. The LED 1a, LED 1b, LED 1c, and LED 1d illuminate the object X, and the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com