Actuating device

A technology of operating device and accommodating sleeve, applied in the field of operating device of valve, can solve the problem of limited possibility of error compensation and achieve the effect of reliable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

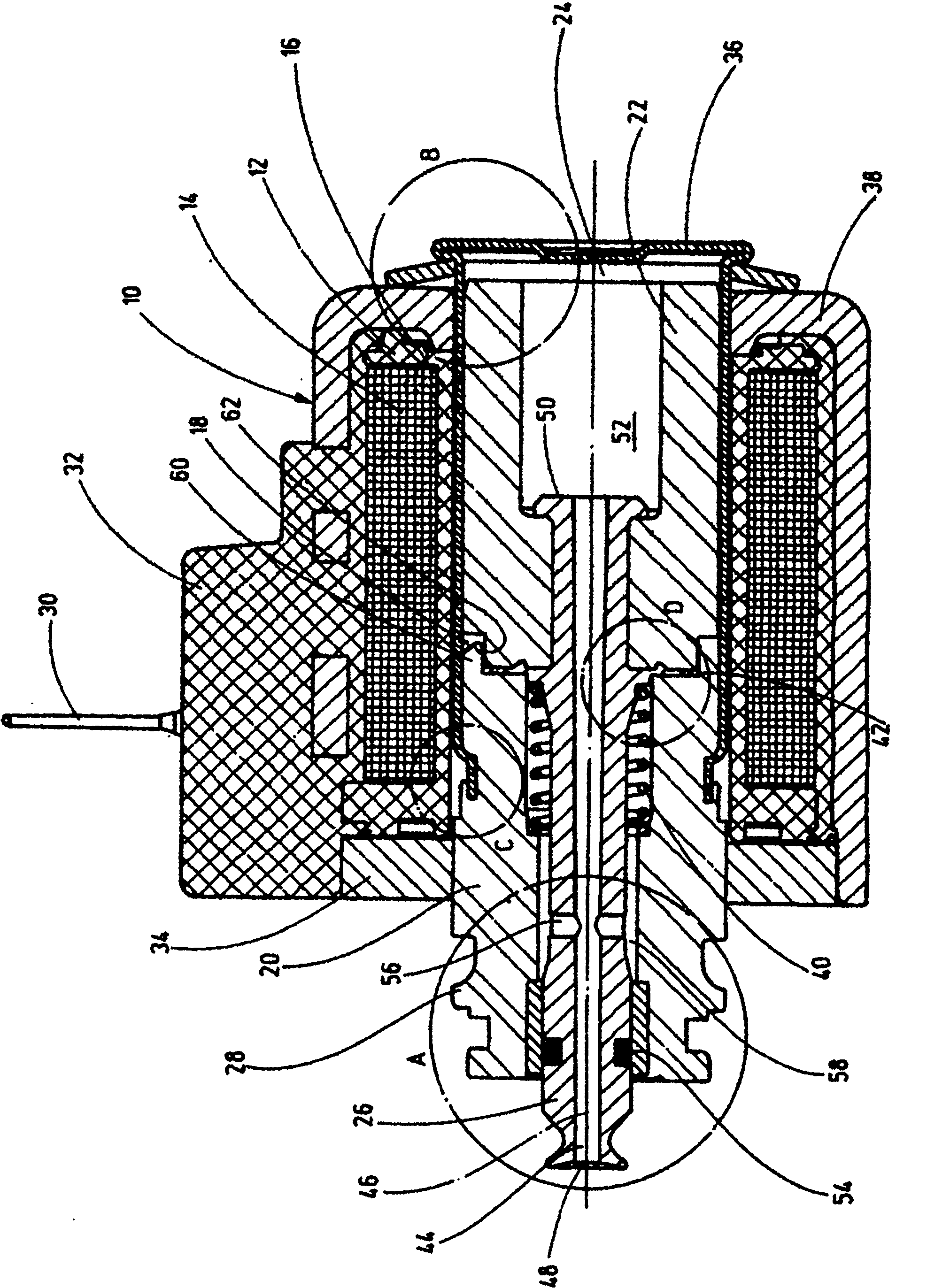

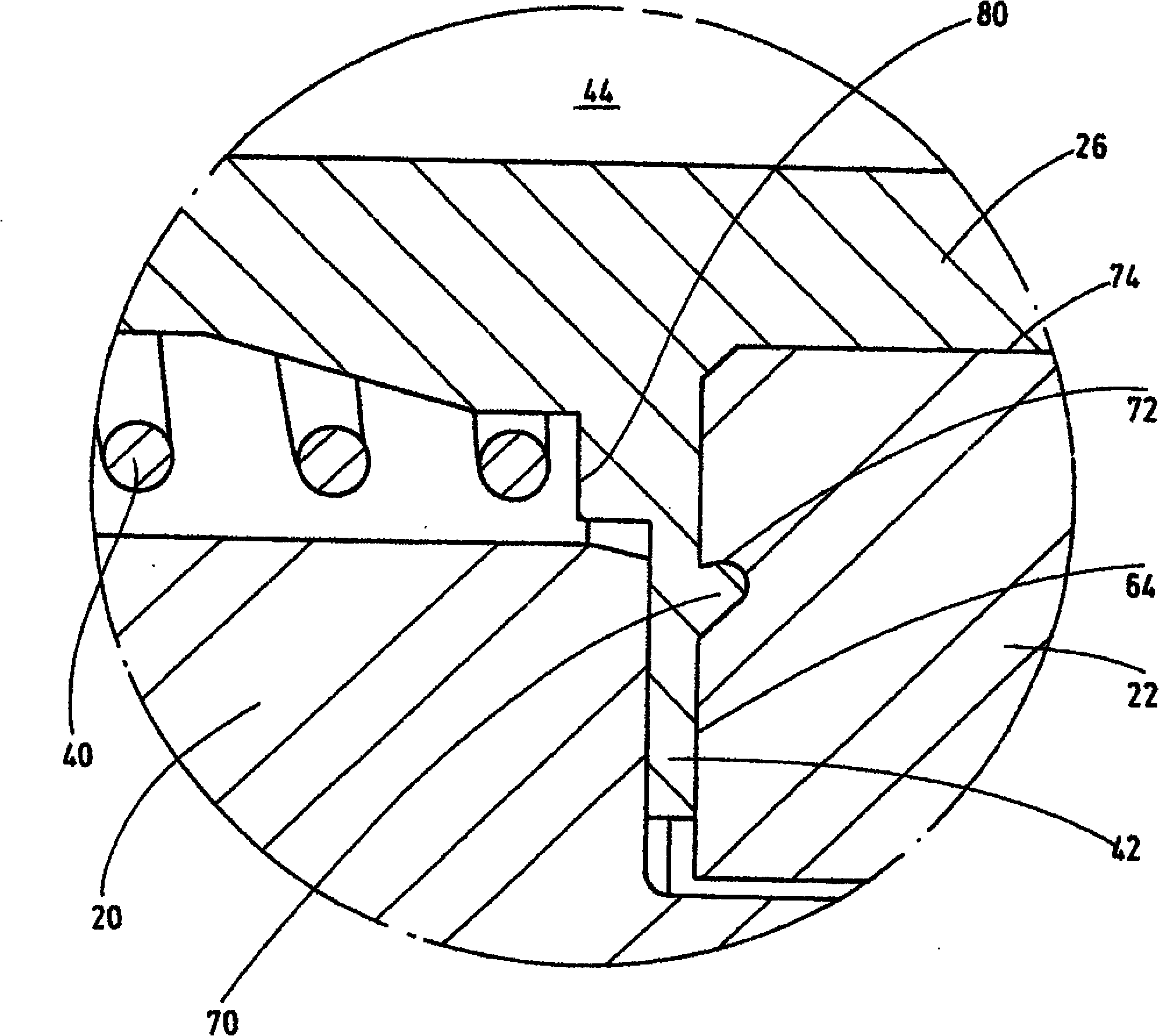

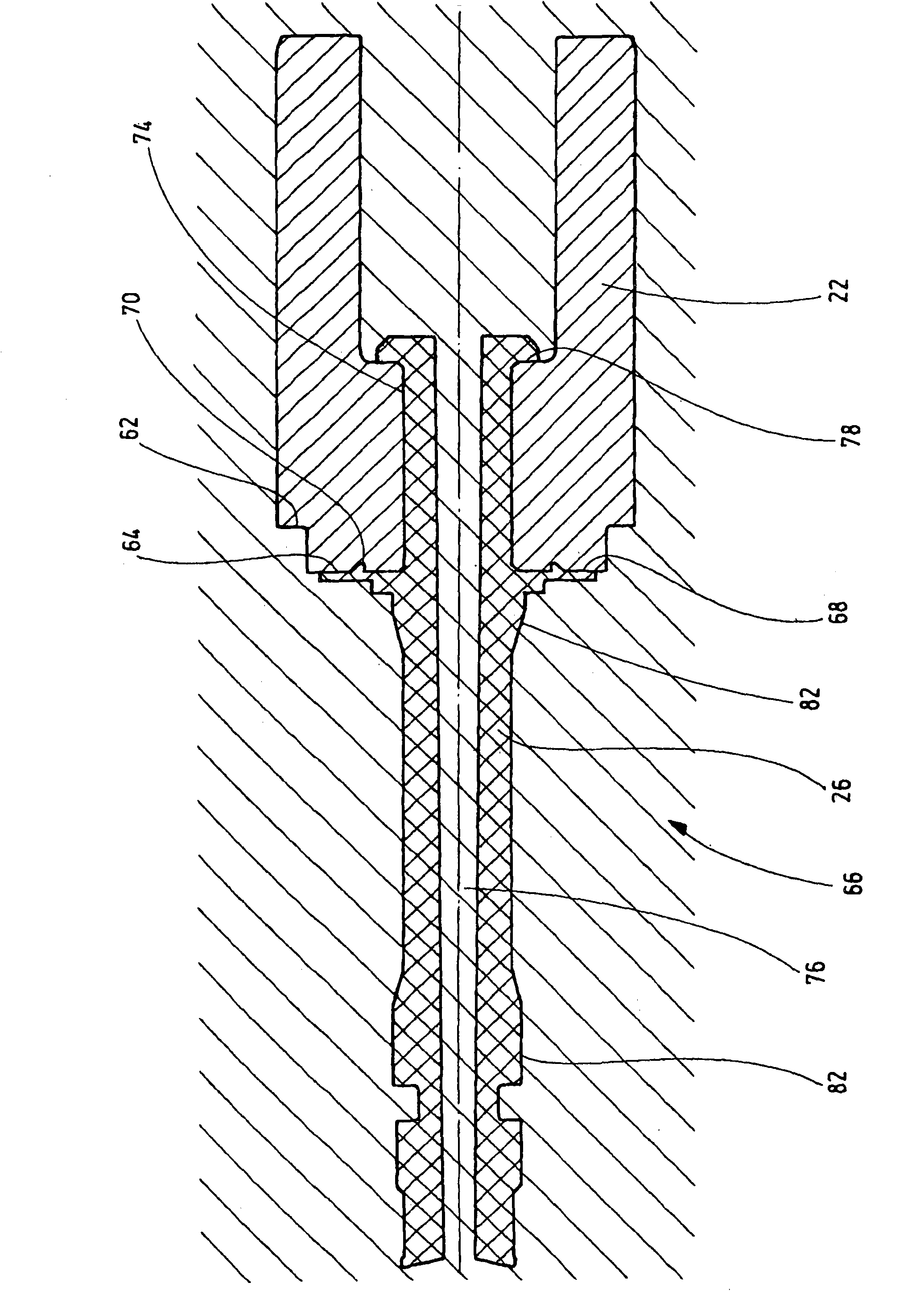

[0024] exist figure 1 The actuating device shown in longitudinal section in FIG. 2 , also referred to in the art as an “actuating and switching magnet”, has a housing indicated overall at 10 in which a coil body 12 with a coil winding 14 is arranged. The coil body 12 at least partially surrounds a pole tube 16 , which is essentially electromagnetically decoupled from the pole core 20 by means of a separation point 18 in the form of a recess. However, such solutions (not shown) are also known in the prior art, in which the corresponding separation points are formed by welded seams or the like. A magnetic armature 22 is guided longitudinally displaceably along the pole tube 16 in the armature chamber 24 , which interacts at its one free front end with a rod-shaped actuating part 26 for actuating conventional designs. Fluid valves (not shown) in the form of, in particular, not shown pneumatic valves. For connecting the valve, the pole core 20 is provided with a connecting flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com