Forming machine

A molding machine and molding unit technology, which is applied in the field of conveying and heating devices of a single feeding device, can solve the problems of insufficient production line capacity, waste of heat energy, and delay in conveying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

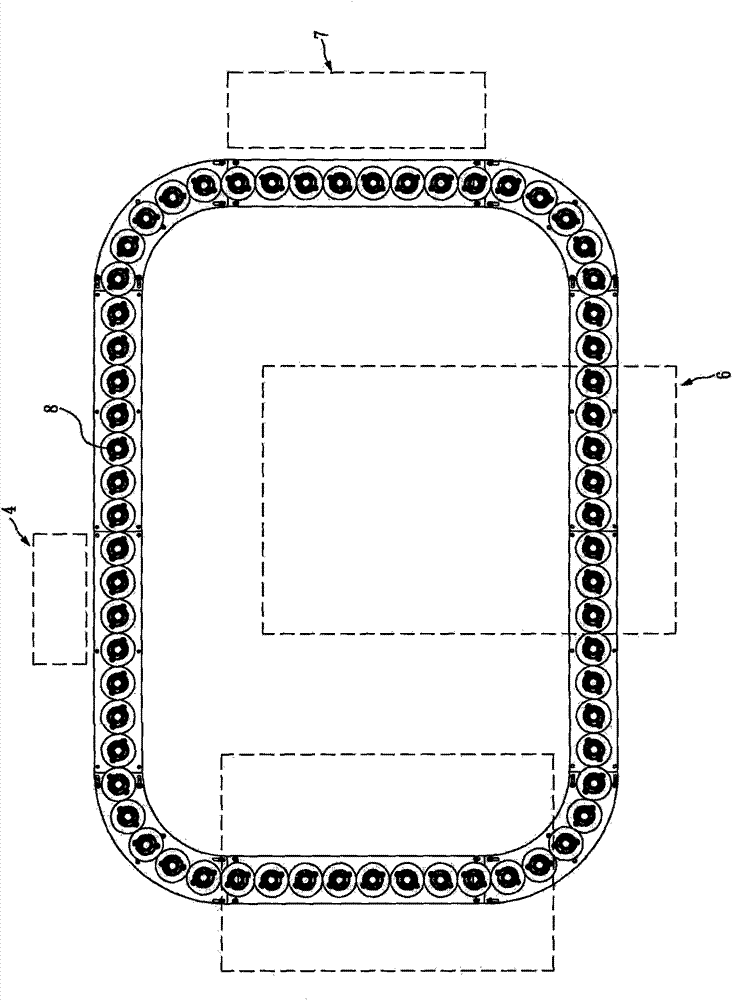

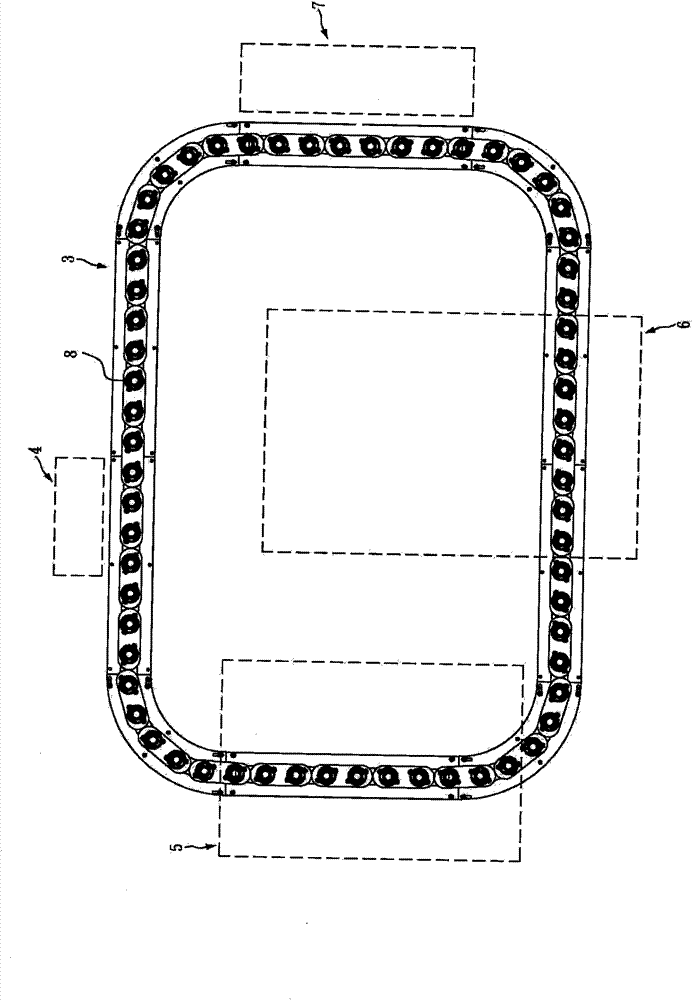

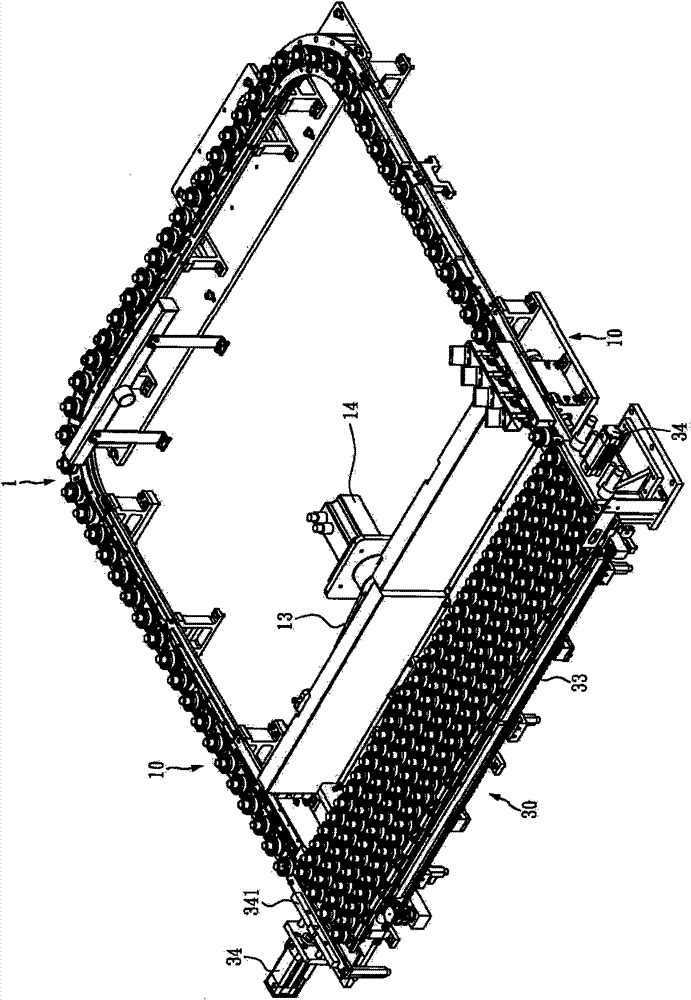

[0025] Such as image 3 and Figure 10 and Figure 11 As shown, the present invention is a molding machine, which mainly includes a conveying unit 10 , a feeding unit 20 , a heating unit 30 , a molding unit 40 , and a bottle discharging unit 50 .

[0026] Such as image 3 As shown, the conveying unit 10 includes a conveying track 11 ; the conveying unit 10 surrounds the feeding unit 20 , the molding unit 40 and a bottle discharging unit 50 along the conveying track 11 . The conveying track 11 is provided with at least two preform groups 60, and each preform group 60 is composed of at least one preform seat 61 linked to each other, wherein the preform seat 61 can carry a work piece; 60 movable links or detachments. The feeding unit 20 fixes the blanks one by one on the blank seat 61 of the conveying unit 10, and at least one row of preform seats 61 can be transported from the feeding unit 20 to The heating unit 30 heats the blank so that it can be stretched and molded. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com