Grouping type mesh screen with continuously adjustable mesh size

A screen and size technology, applied in the field of screens that can continuously adjust the size of the screen holes, can solve the problem of not being able to meet the screening requirements, and achieve the effects of high screening accuracy, accurate screen size, and convenient and fast operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

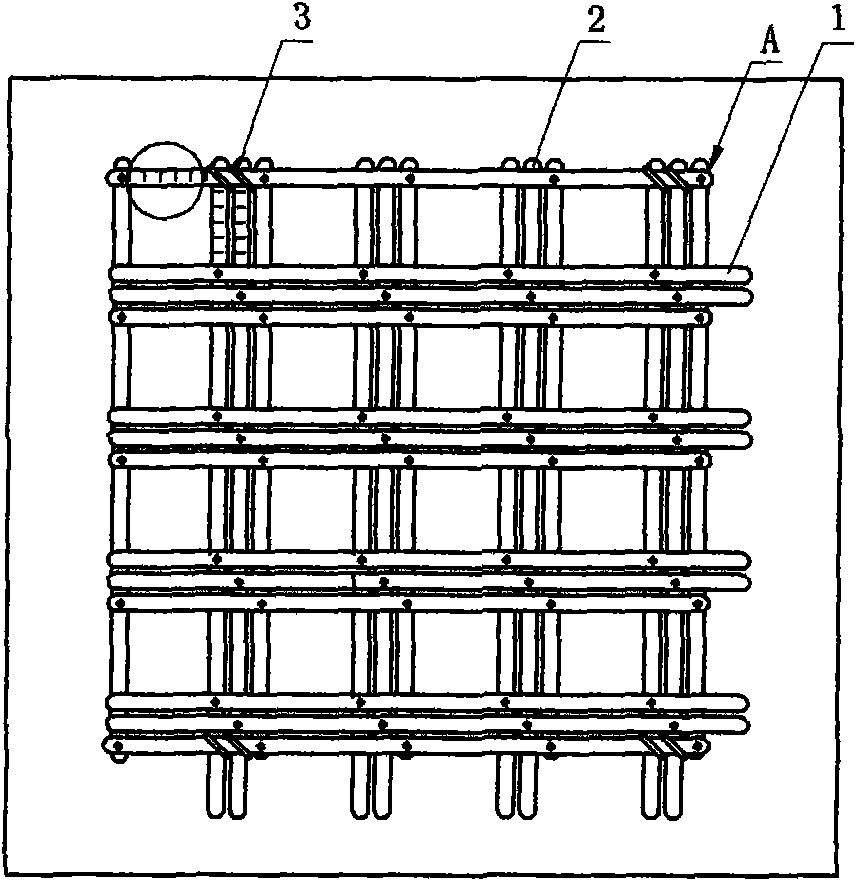

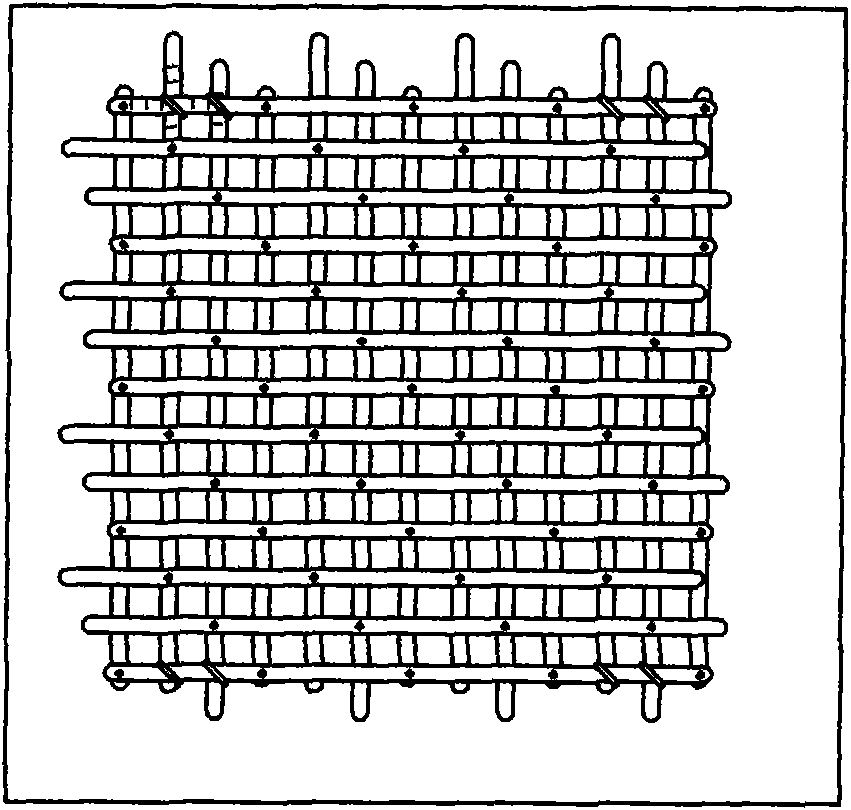

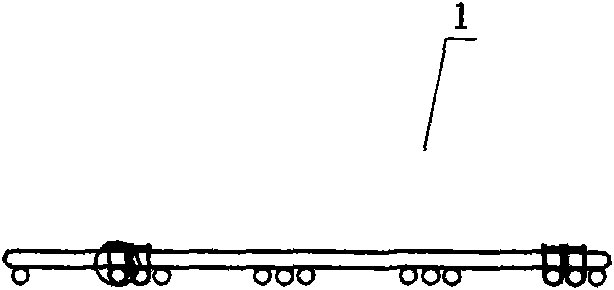

[0020] The screen mesh that can continuously adjust the size of the screen hole is composed of a horizontal bar 1, a vertical bar 2, and a hydraulic locking device 3. The horizontal bar and the vertical bar are uniformly interlaced to form a screen hole.

[0021] All the horizontal bars that make up the screen are located on the same plane, and all the vertical bars are located on another plane that is close to the horizontal bar. The horizontal bars and vertical bars are interwoven to form a screen. The formed screen is divided into several groups. The number of groups depends on the actual situation. Need to set. One of the screens A is fixed, and the other groups can move relative to A in the X-axis and Y-axis directions. figure 1 with figure 2 A schematic diagram showing two sets of active frames.

[0022] The cross bars and longitudinal bars constituting the same group of sieves are fixed together at each intersection point, and the material of the poles (ie cross bars...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com