Louver in hollow glass

A louver and glass technology, applied in the field of louvers, can solve the problems of incomplete turning, hollow louver glass shading, shading coefficient and thermal insulation performance deterioration, and achieve high shading performance and thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

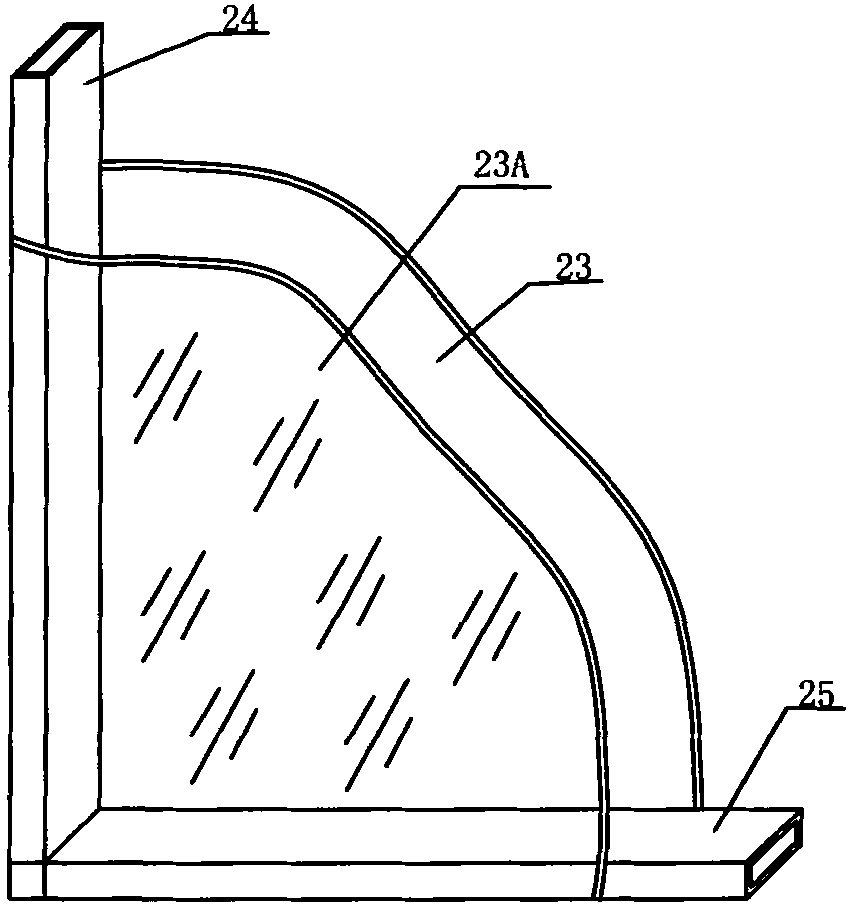

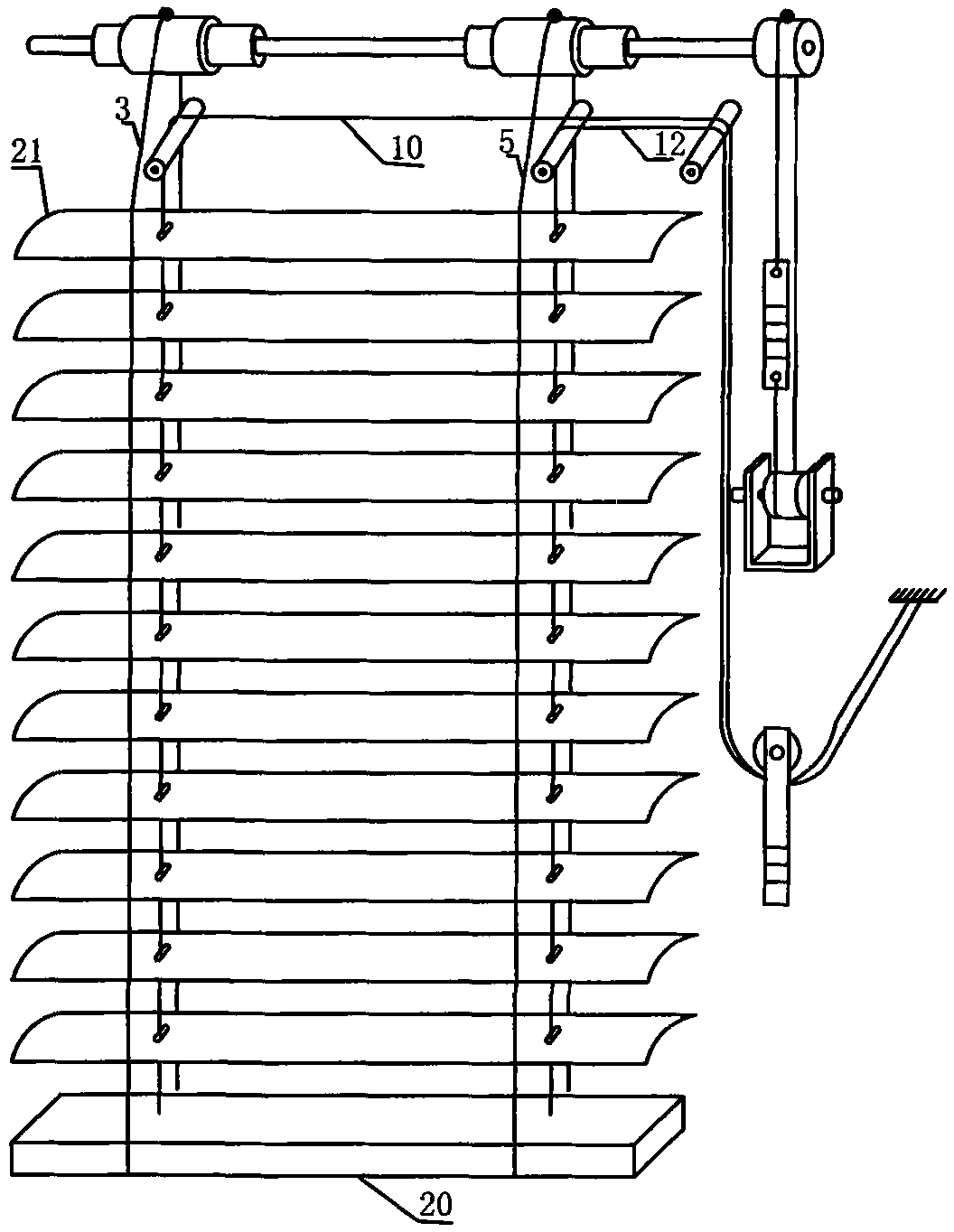

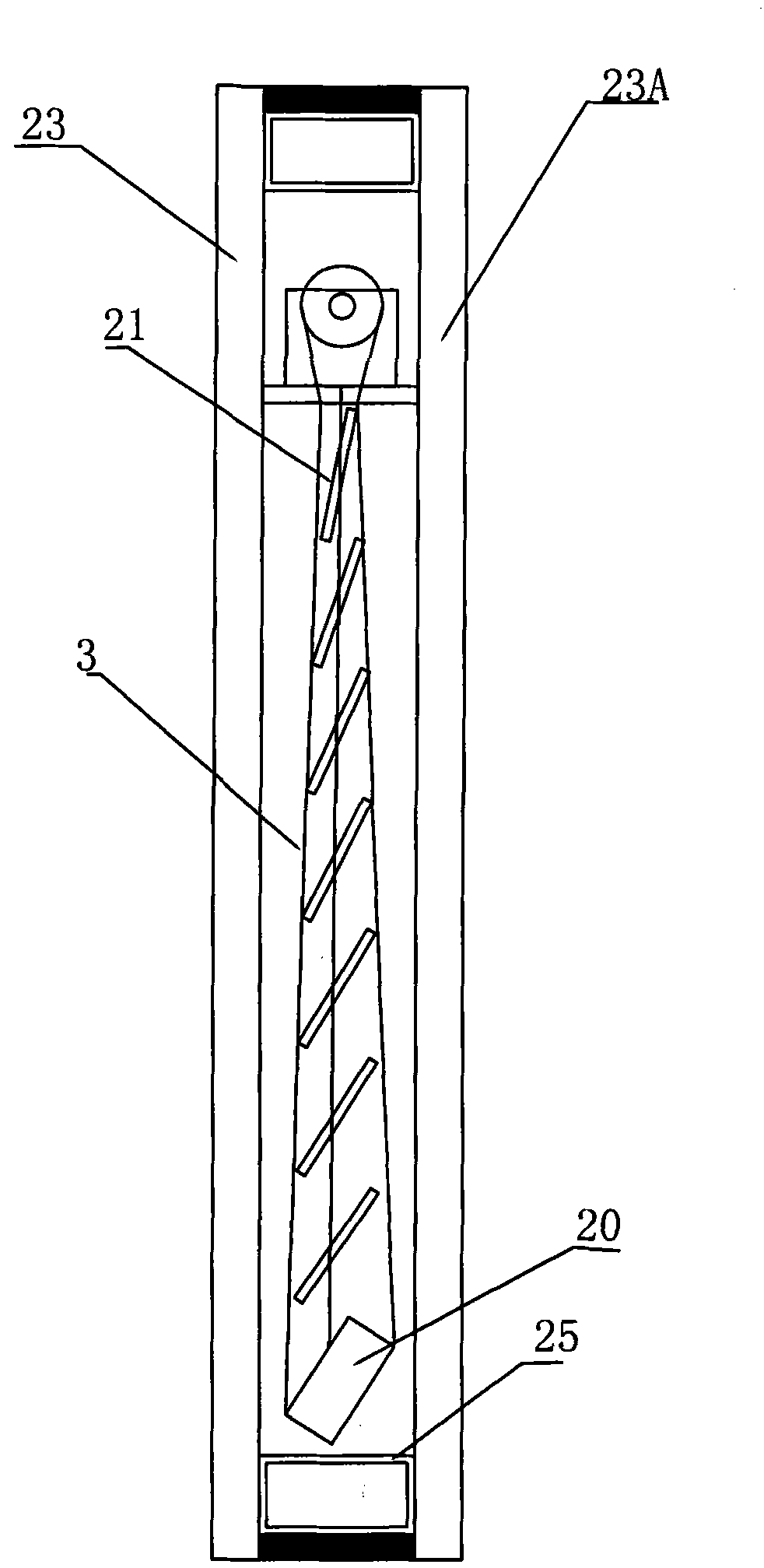

[0020] Figure 2A , Figure 2B is a structural schematic diagram of an embodiment of the present invention; Figure 2C is a schematic side view of an embodiment of the invention showing the louvers fully closed.

[0021] see Figure 2A , Figure 2B , The inside of the louver counterweight bottom beam 20 is equipped with iron wires 28 and iron wires 29 near the long sides of the left and right sides of the glass. Several magnets 16 are housed in the inside of the hollow glass lower support frame 25, only one of which has been shown in the figure. One can be set at the left and right ends of the lower support frame 25;

[0022] When the user operates the leaf turning mechanism of the shutter, the counterweight bottom beam 20 will also turn over accordingly, taking the side of the iron wire 28 as an example. The position of the iron wire 28 on one side descends and gradually approaches the lower supporting frame 25 of the insulating glass, while the position of the iron wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com