Yarn feeding device of computer silk stockings machine

A technology of yarn feeding device and stockings machine, which is applied in textiles and papermaking, weft knitting, knitting, etc. It can solve the problems of unable to meet the needs of the market, slow response speed, unstable yarn feeding, etc. Accurate, improve performance, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

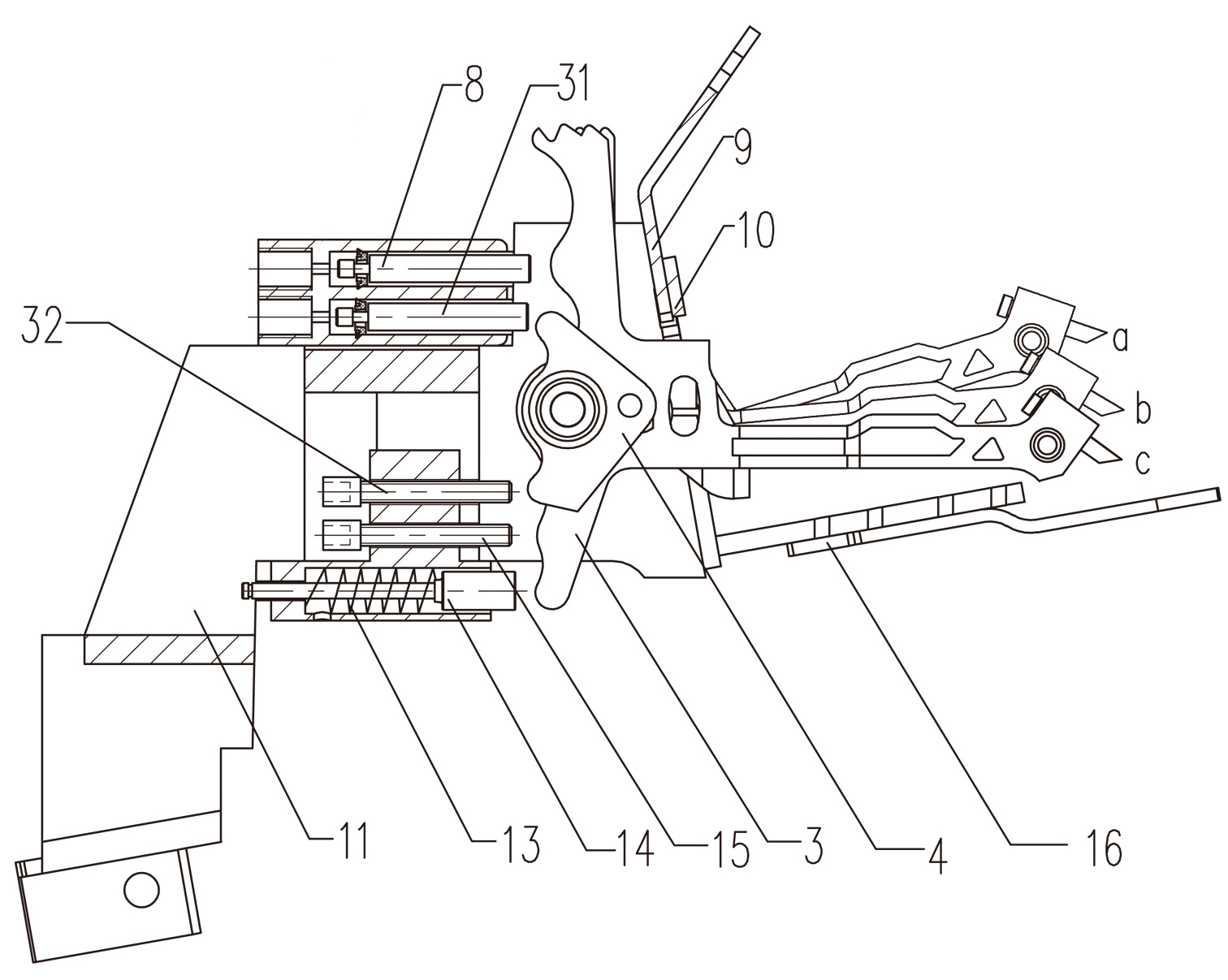

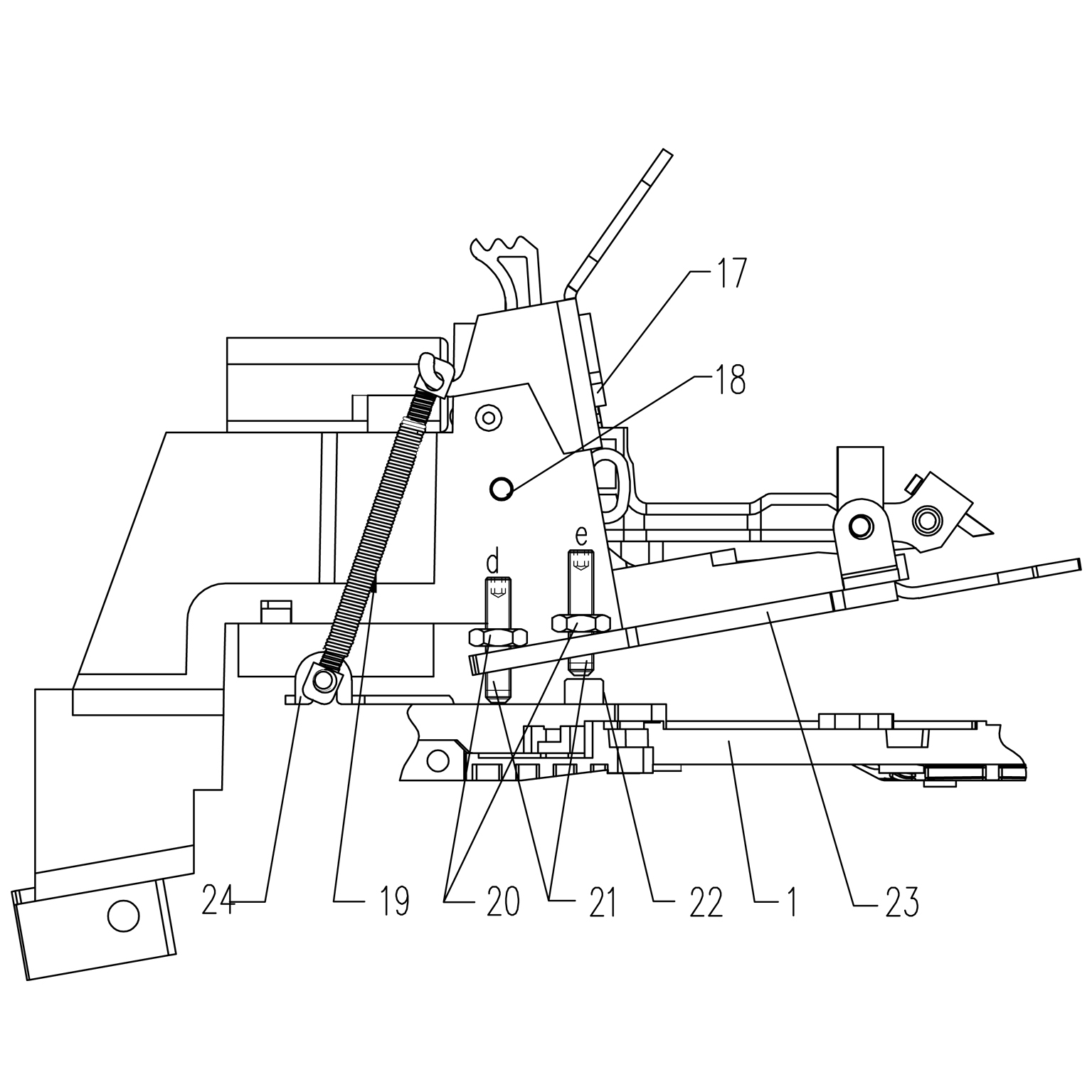

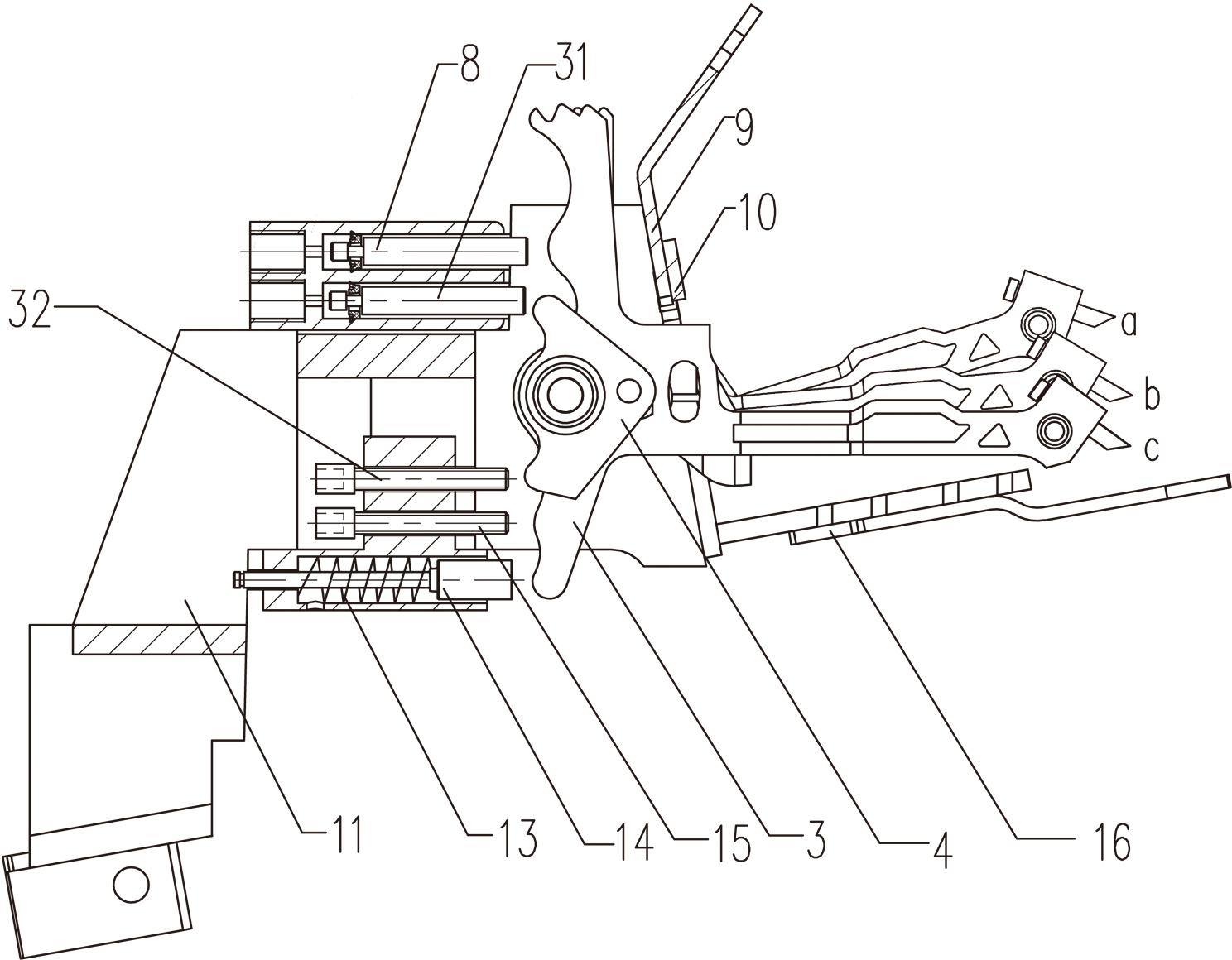

[0018] Referring to the accompanying drawings, this embodiment includes a shuttle cylinder 11 and 6 yarn feeding shuttles 3. The shuttle cylinder 11 is provided with a first cylinder piston 8, a second cylinder piston 31, a push rod 14 with a spring 13 and an upper , lower limit screws 32, 15, the 6 yarn feeding shuttles are connected to the shuttle cylinder body 11 by passing through straight pins 18; The push rod 14 of 13 corresponds to the lower limit screw 15, and cooperates with the corresponding first cylinder piston 8 and the push rod 14 of the band spring 13.

[0019] Each yarn feeding shuttle 3 has a catch 4, and the catch 4 is coaxially installed on the shuttle cylinder 11 with the yarn feeding shuttle 3; the tail of the catch 4 is connected with a second cylinder piston 31 and an upper limit screw 32, and cooperate with the corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com