Semiautomatic tube-tops die-pressing device

A semi-automatic, breast mold technology, applied in bras, clothing, bras, etc., can solve problems such as tube tops that cannot be achieved, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

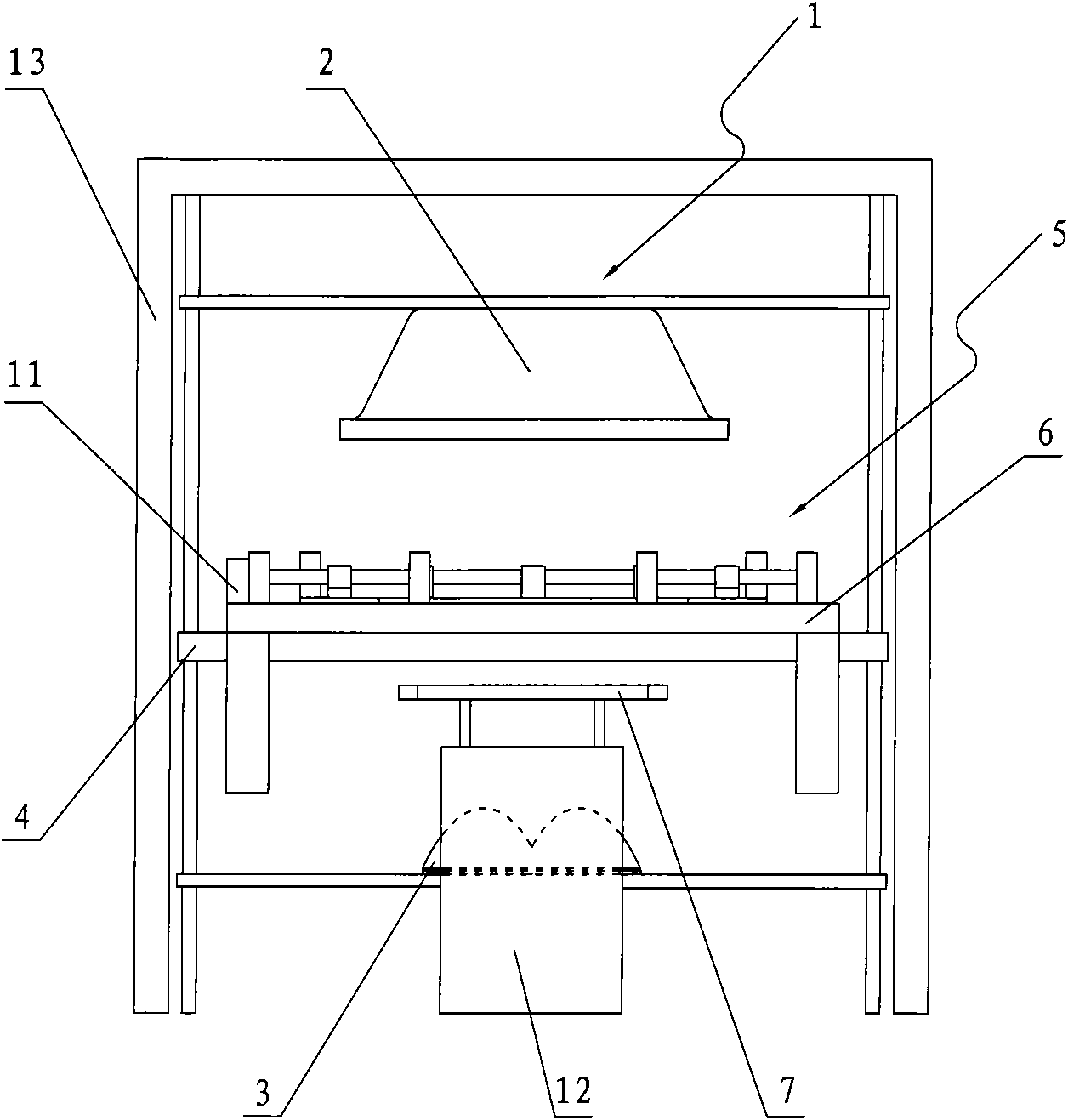

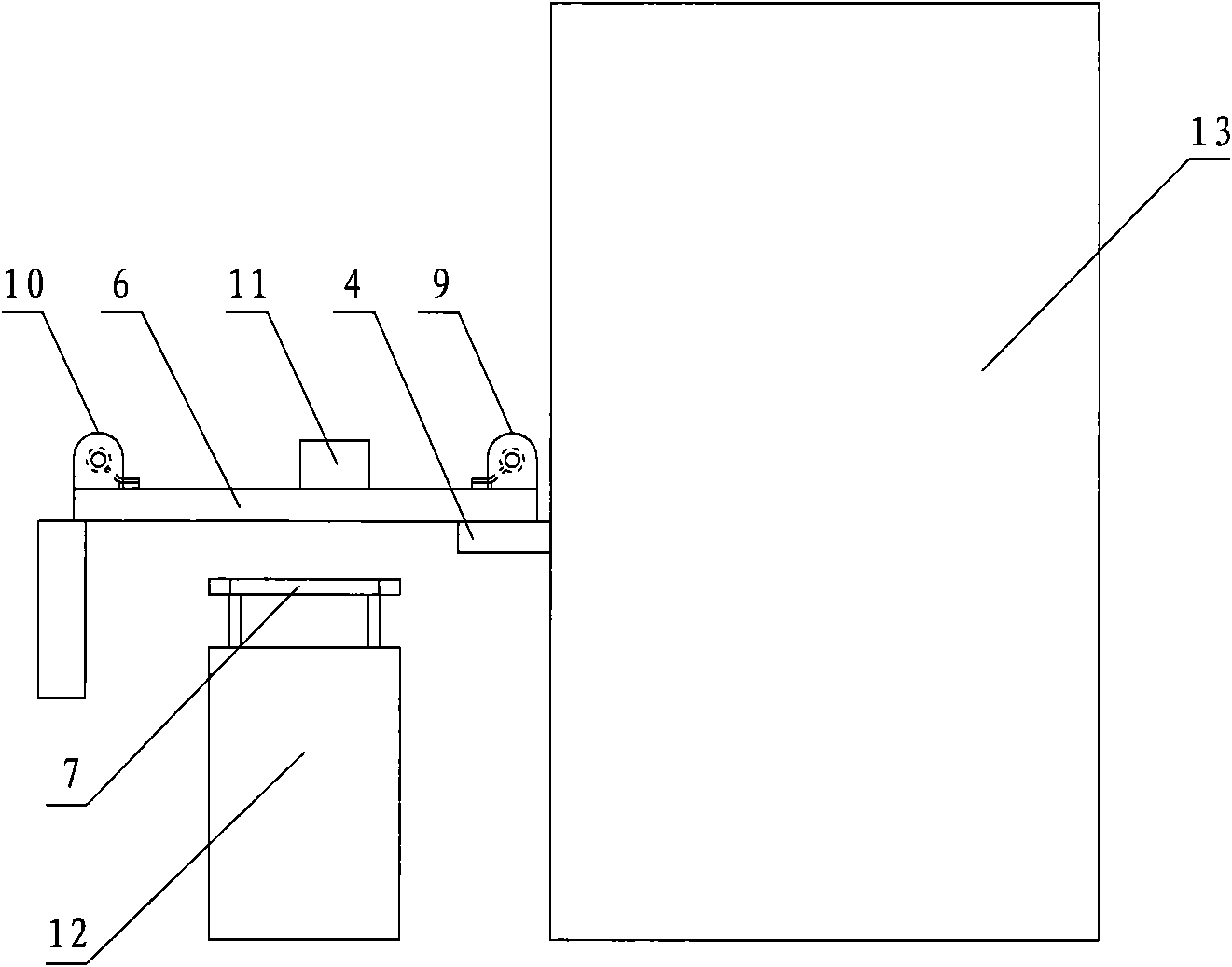

[0020] Embodiment one: see attached figure 1 shown.

[0021] A semi-automatic tube top molding device, including a molding device 1 arranged on a frame 13, the molding device 1 includes an upper mold 2 and a lower mold 3 for molding, and a horizontal direction is arranged between the upper mold 2 and the lower mold 3 Iron frame 4;

[0022] The semi-automatic tube top molding device also includes a control device and a feeding device 5 arranged on the molding device;

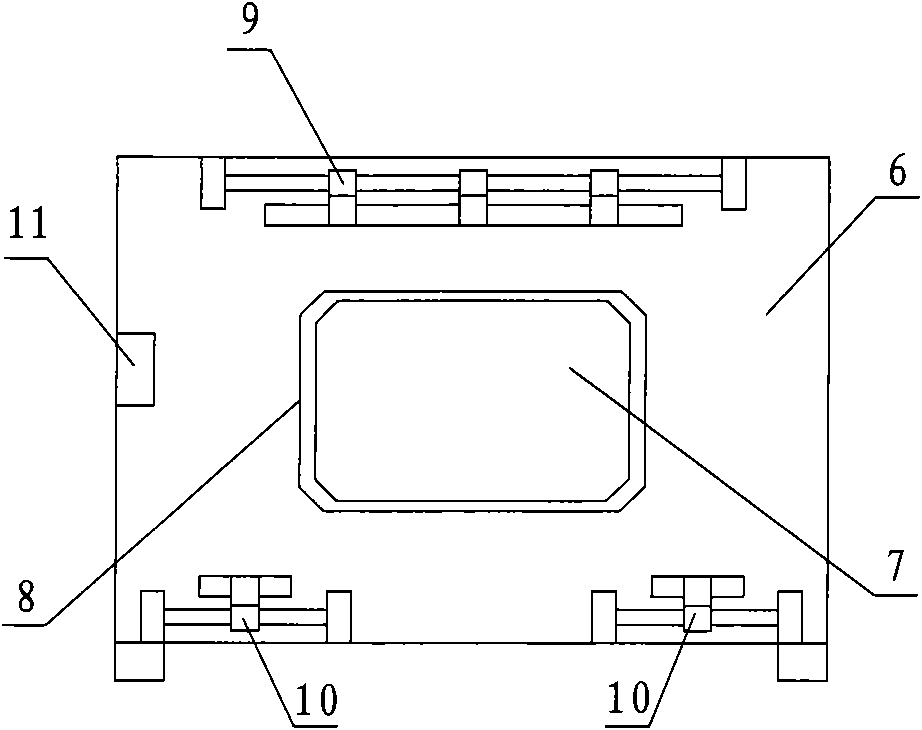

[0023] The feeding device 5 includes a workbench 6 and a lifting pallet 7 which are arranged on the iron frame 4 and can move horizontally relative to the iron frame 4;

[0024] The workbench 6 has a central hole 8, and the workbench 6 is controlled by the control device to move. One side of the workbench 6 is provided with a first clamping claw 9, and the other side of the workbench 6 is provided with a second clamping claw 10. A clamping jaw 9 and a second clamping jaw 10 are controlled by the control device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com