Continuous cold-roll-forming shaping method of straight-hook-shaped corner pile

A corner pile and cold-bending technology, which is applied to sheet pile walls, buildings, and infrastructure projects, can solve problems affecting project quality and achieve the effects of improving project quality, widening options, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

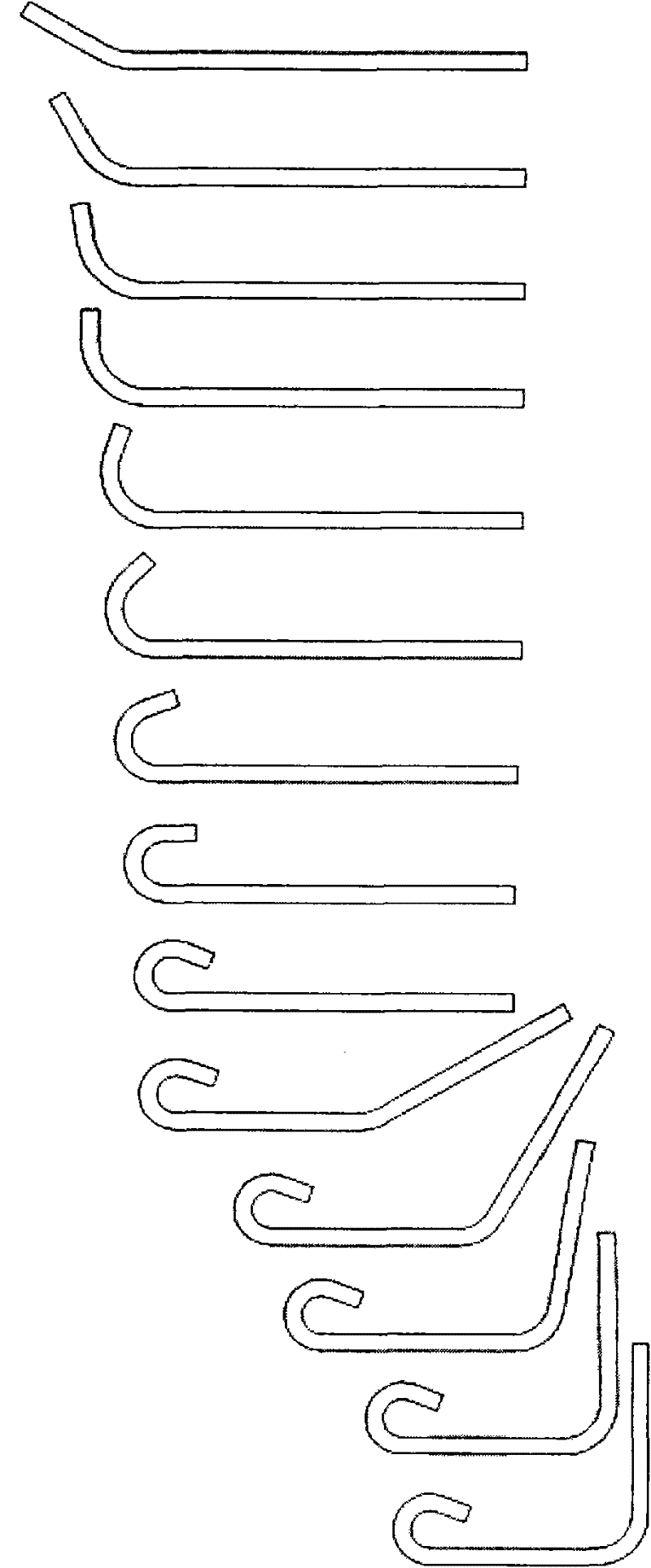

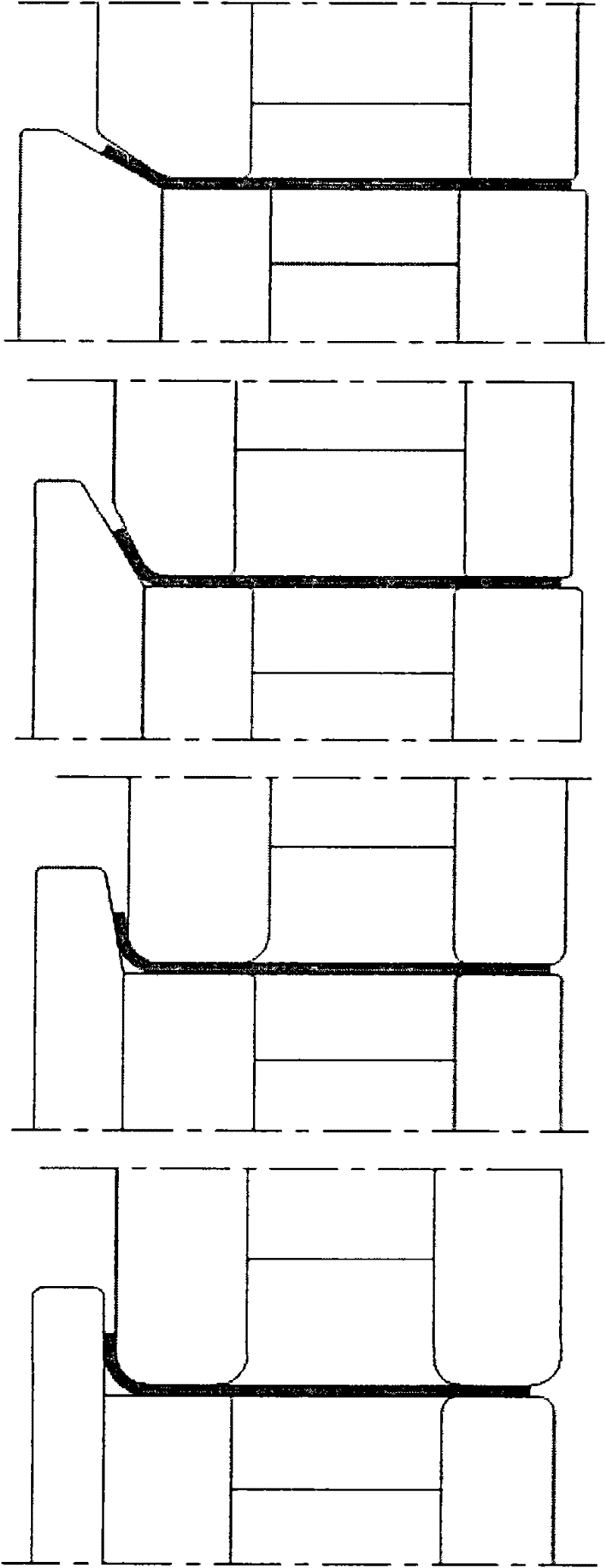

[0041] Such as Figure 1-5 shown.

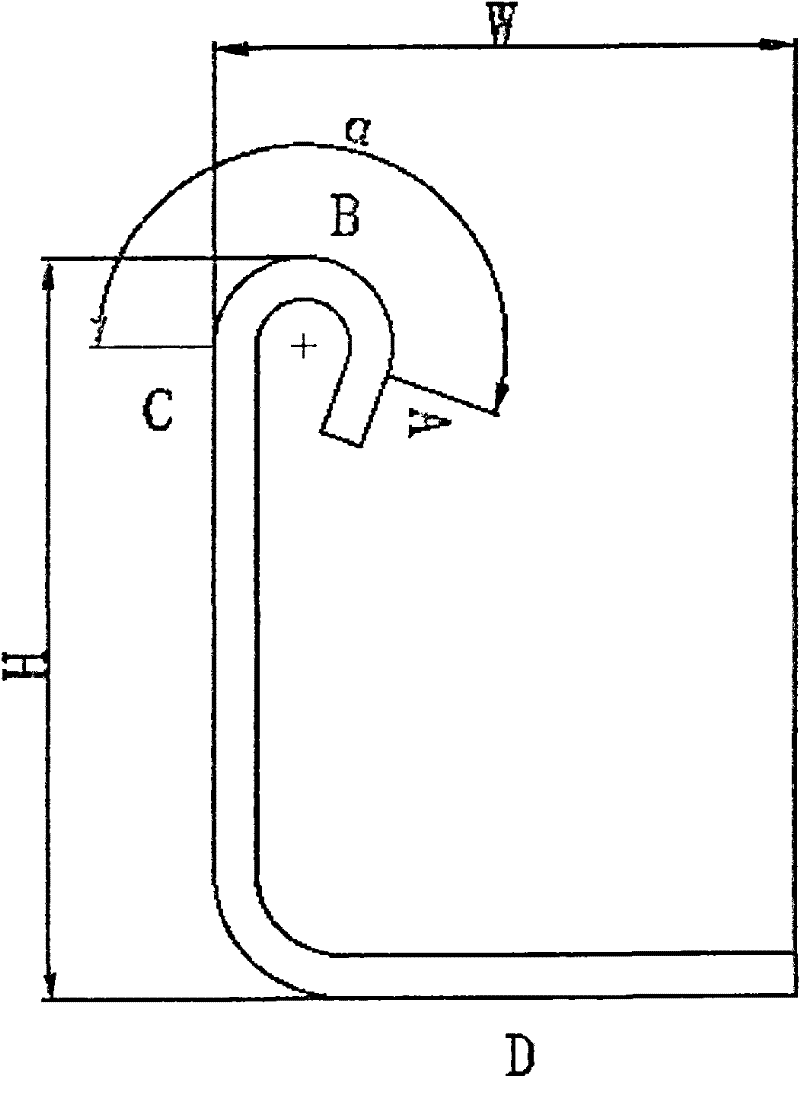

[0042] A straight hook-shaped corner pile, which is composed of a straight hook side C, a horizontal side D, a circular arc segment B and an oblique hook side A, the straight hook side C and the horizontal side D are perpendicular to each other, and the circular arc segment B is respectively connected to the straight hook side C and oblique hook side A are connected to form a lock, the angle between oblique hook side A and straight hook side C is 200 degrees, and the thickness of the selected raw material strip steel can be selected according to needs, generally 5-16 mm, such as figure 1 As shown, the angle α between the oblique hook side A and the straight hook side C is 200 degrees.

[0043] The present invention adopts the method of continuous roll-type cold-bending forming to directly obtain continuous right-ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com