Stack-type multi-gap gas switch

A gas switch, multi-gap technology, used in spark gaps, electrical components, spark gap components and other directions, can solve the problems of cumbersome installation process and poor installation accuracy, shorten the assembly time, eliminate the influence of human factors, and the installation process. Simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

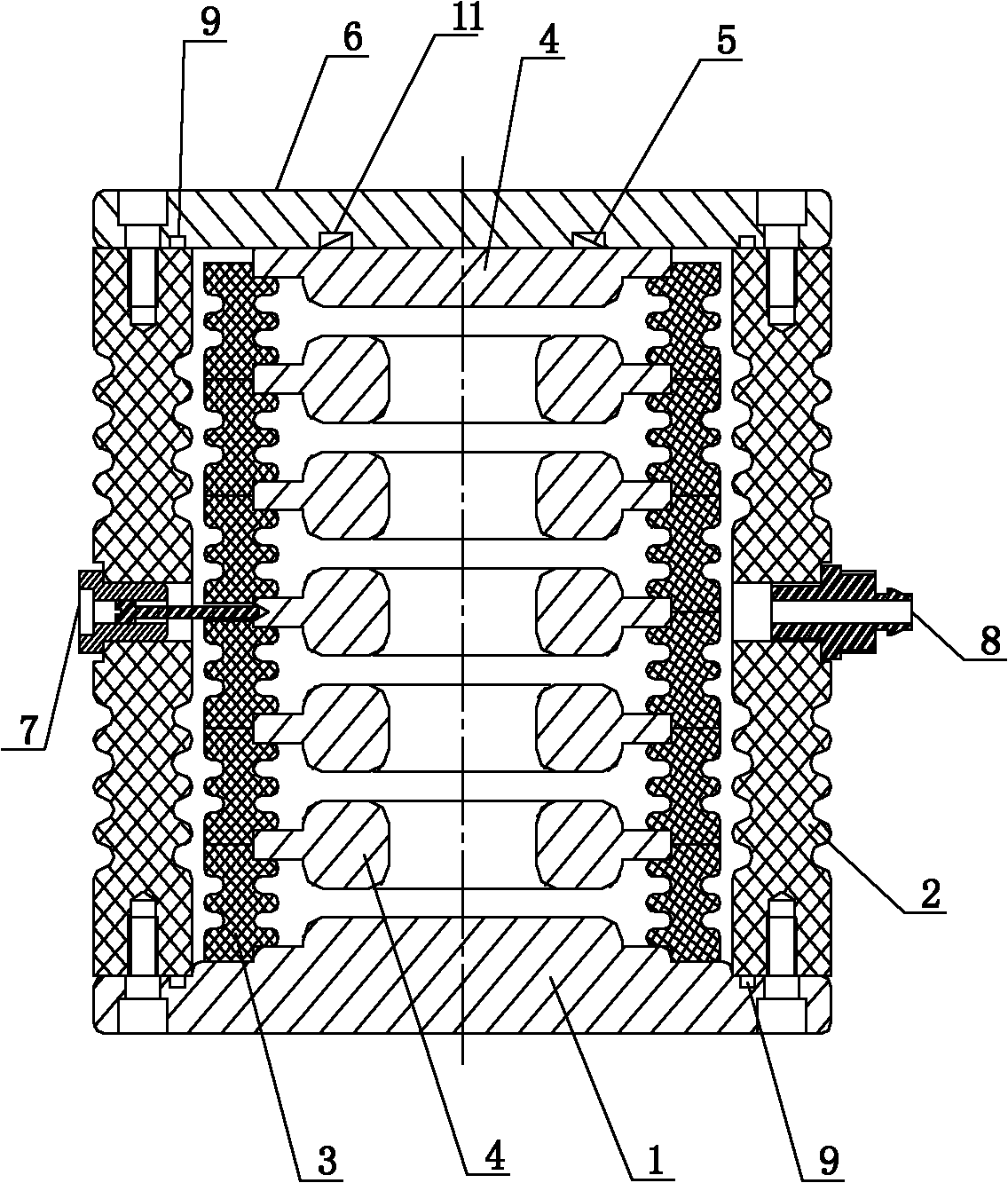

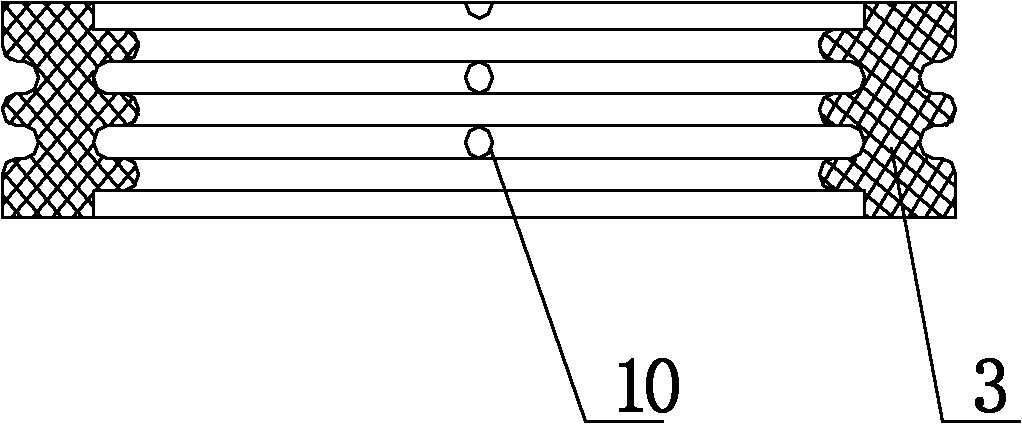

[0026] The stacked multi-gap gas switch of the present invention is cylindrical and mainly includes an outer insulating cylinder, an upper cover plate at the top and a lower cover plate at the bottom, six electrodes, six insulating spacers and an elastic metal ring. The outer insulating cylinder is cylindrical, and the middle plane is provided with trigger connectors and gas nozzles. The upper cover and the lower cover are disc-shaped, fastened to both ends of the outer insulating cylinder by screws, and a rubber sealing ring is installed between the cover and the outer insulating cylinder, and the lower cover is also used as one of the electrodes. The electrodes and insulating pads are ring-shaped, and they are nested together to form a stack assembly. There are air holes on the outside of the insulating pads. All electrodes and insulating pads are located inside the outer insulating cylinder and are coaxial with the outer insulating cylinder. The elastic metal ring is a tape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com