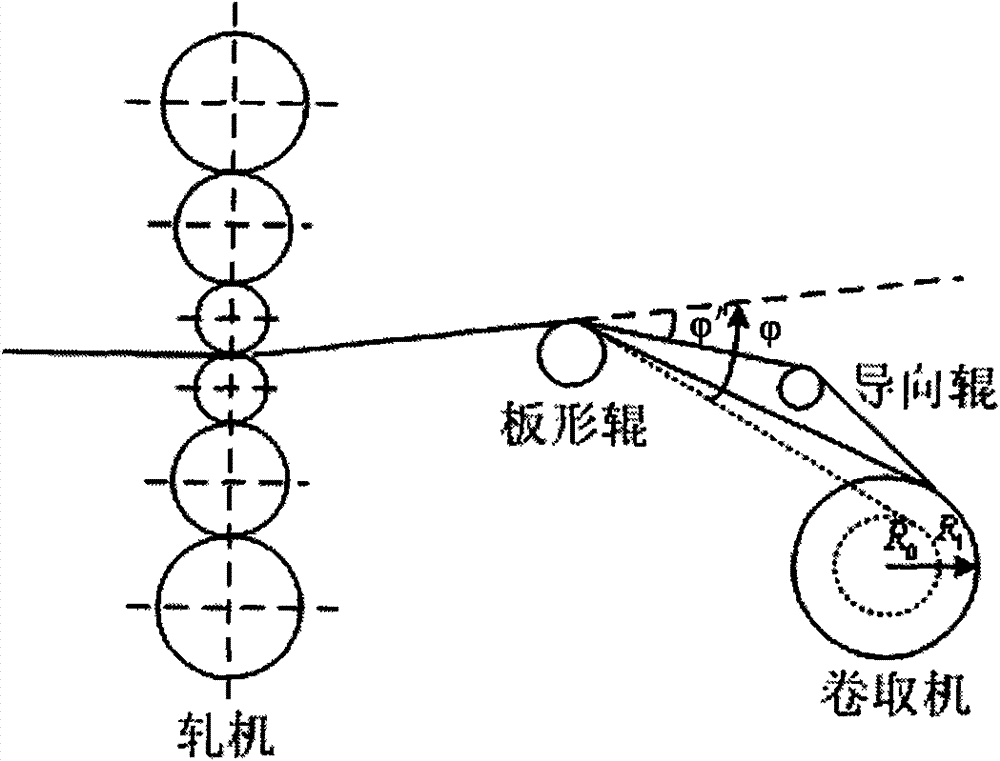

Variable wrap angle flatness control parameter processing method for cold rolling mill

A technology for controlling parameters and processing methods, which is applied in the field of cold-rolled strip, and can solve the problem of no guide rollers and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

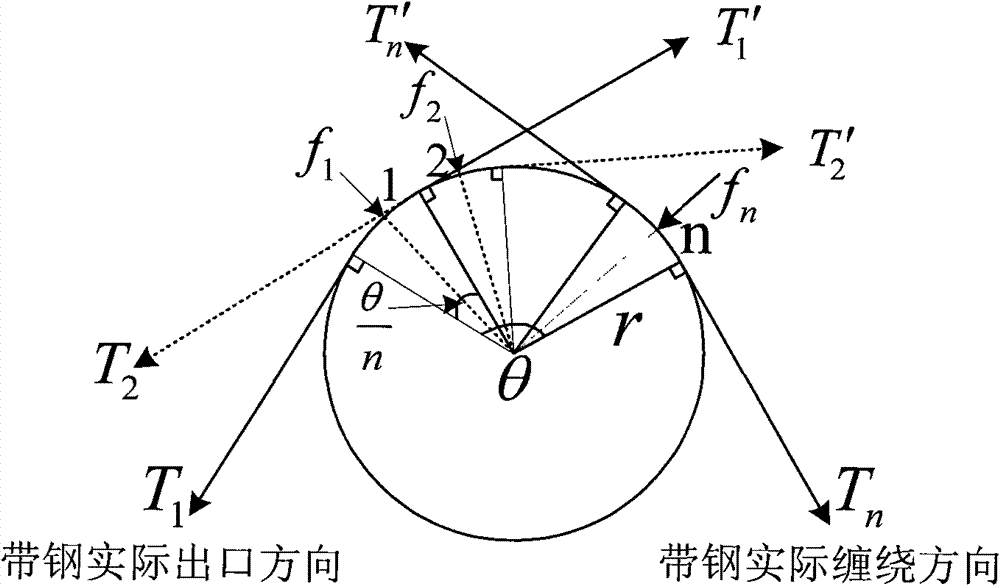

Method used

Image

Examples

specific Embodiment

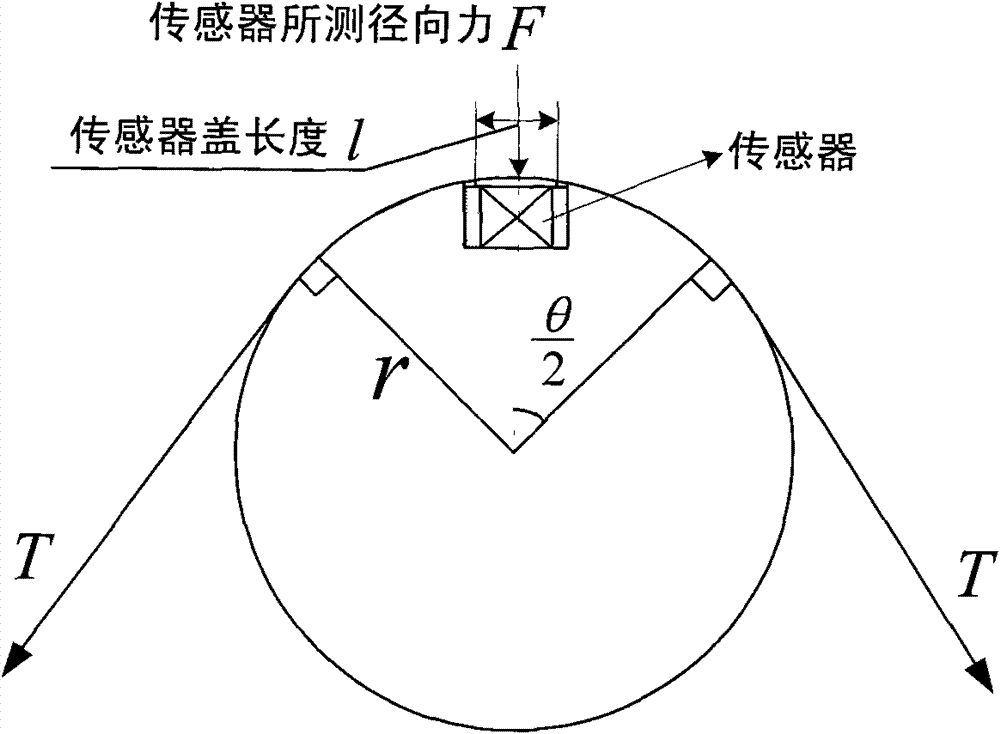

[0108] This embodiment discloses the flatness measurement and calculation process of a 1250 single-stand six-high reversing cold rolling mill. The coiler is in the upper coiling mode. There is no pressure roll between the coiler and the exit of the rolling mill, and the wrap angle changes in real time. The flatness measurement device adopts the domestically produced non-roller ring type flatness roller [roller diameter 350mm, number of measuring sections 23, length of the roller body 1350mm, width of the sensor cover 60mm]. Product specifications (thickness × width): 0.6mm × 1020mm, material: ST12, rolling speed 500m / min-600m / min, strip outlet temperature 50-60 degrees Celsius.

[0109] (1) Calculation of critical wrap angle

[0110] The critical wrap angle is:

[0111] θ = l r · 180 π

[0112] Among them, l=0.06m, r=0.175m, brought in to get θ=19.64 degrees

[0113...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com