Full-automatic railway transportation dust suppression sprinkling system

A technology of railway transportation and spraying system, which is applied in the direction of railway auxiliary equipment, spraying devices, liquid spraying devices, etc. It can solve the problems of overspraying, less spraying, unevenness, and single function, so as to prevent freezing blockage, ensure uniform spraying, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

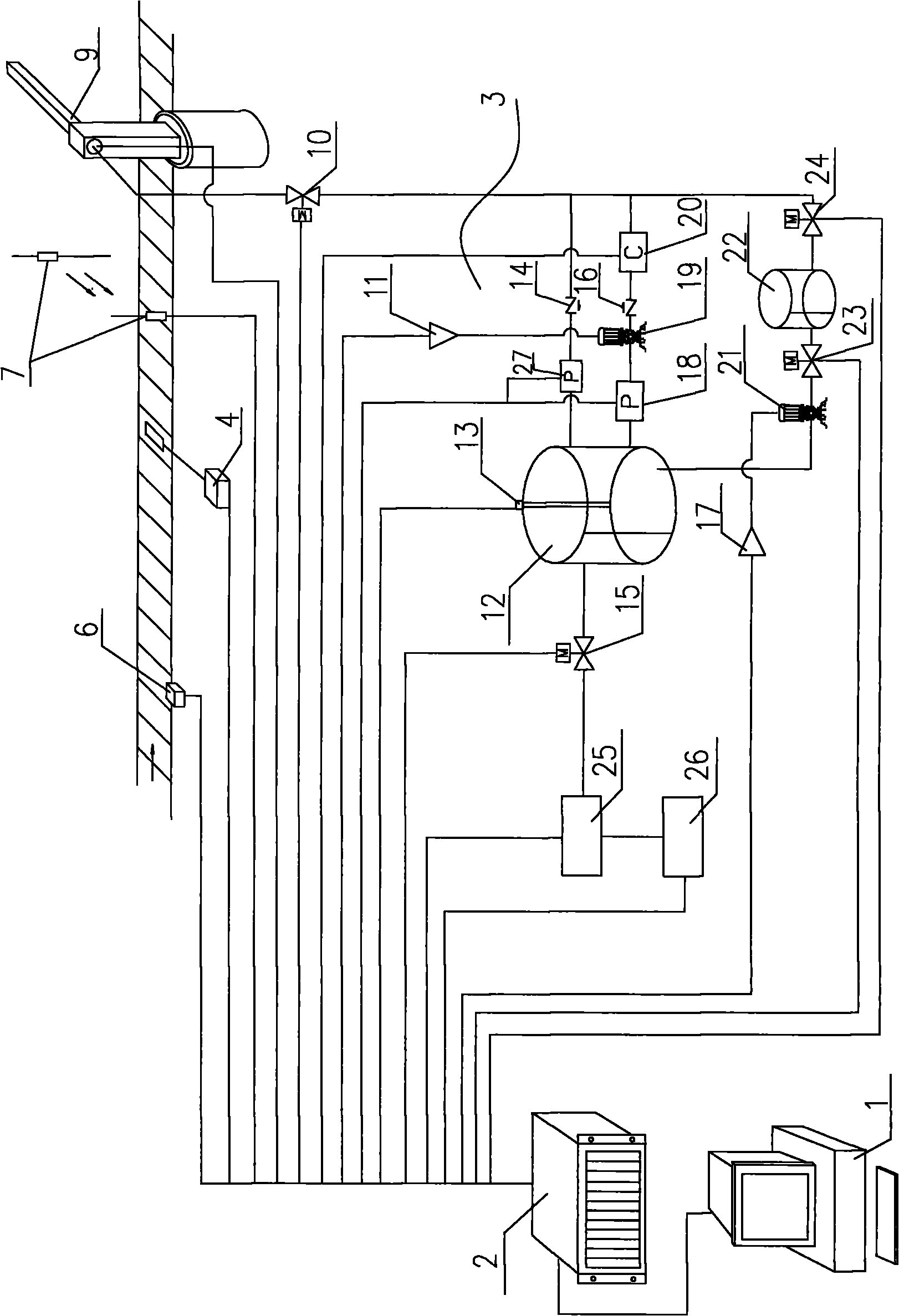

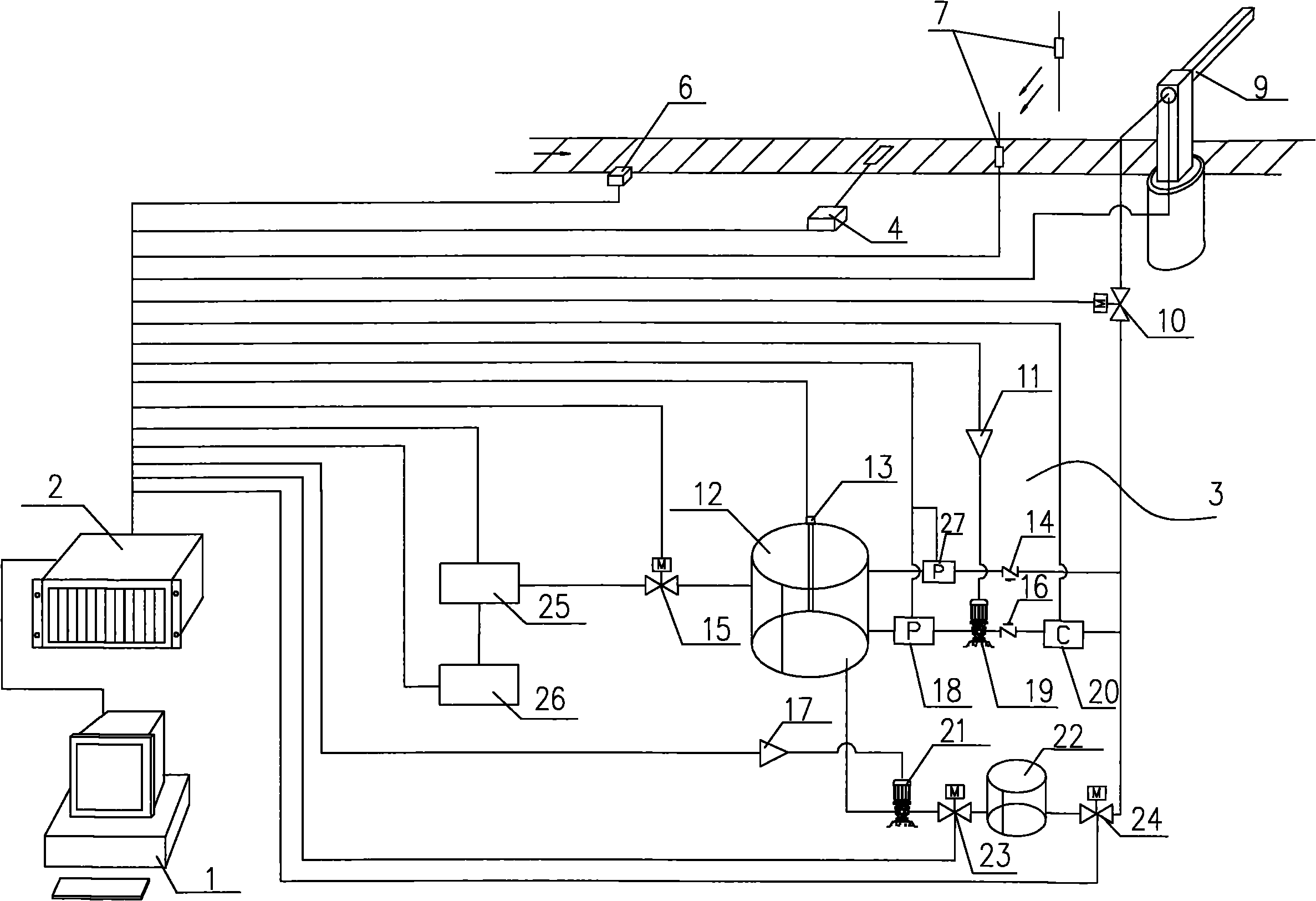

[0023] The present invention will be further described below in conjunction with accompanying drawing.

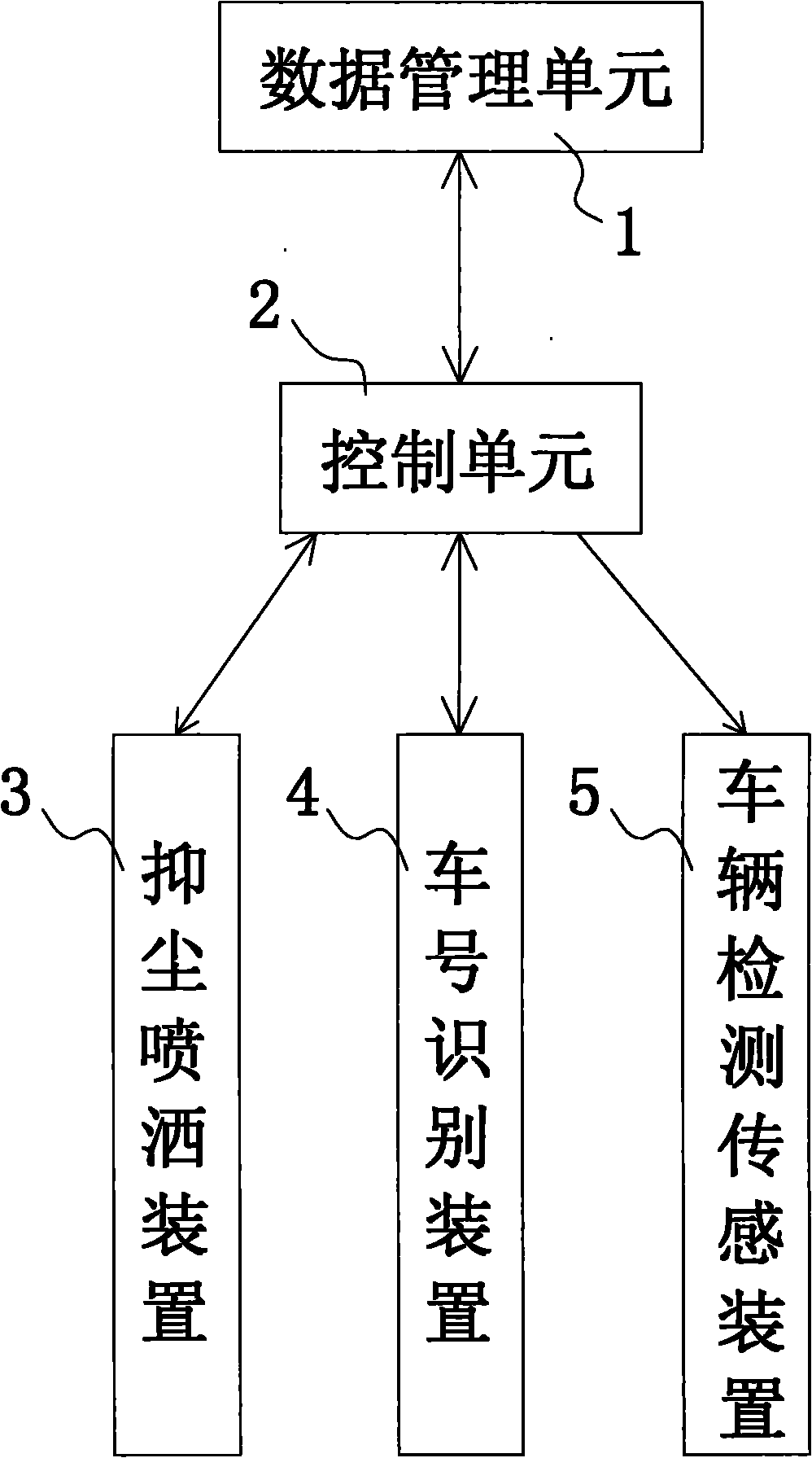

[0024] refer to figure 1 , which is a block diagram of a full-automatic railway transportation dust suppression spraying system of the present invention. A fully automatic railway transportation dust suppression spraying system, which includes a data management unit 1, a control unit 2, a dust suppression spraying device 3, a car number identification device 4, and a vehicle detection sensor device 5; The unit 1, the dust suppression spraying device 3, the vehicle number identification device 4, and the vehicle detection sensor device 5 are connected.

[0025] Data management unit 1: It is used to complete the reading of vehicle number data, spray flow, solution concentration and other information, generate data and store it in the database, and provide basic data for various reports or applications.

[0026] Control unit 2: It is used to control the dust suppression spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com