Ground well casing capable of preventing mining damage

A surface drilling and casing technology, applied in the direction of drilling pipes, casings, drilling equipment, etc., can solve the problems that affect the smooth drainage of gas and be easily damaged, so as to reduce damage accidents and ensure smooth progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

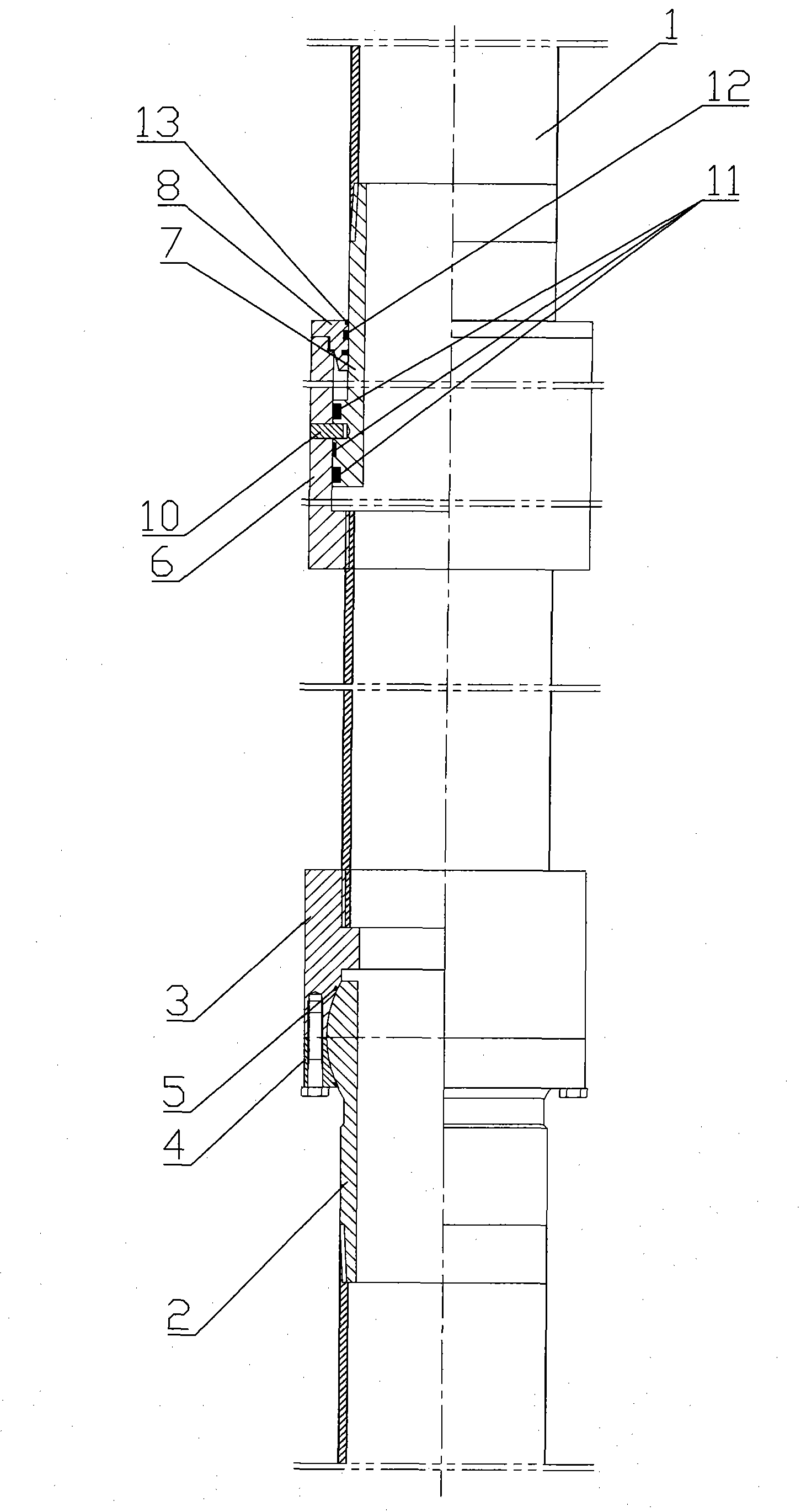

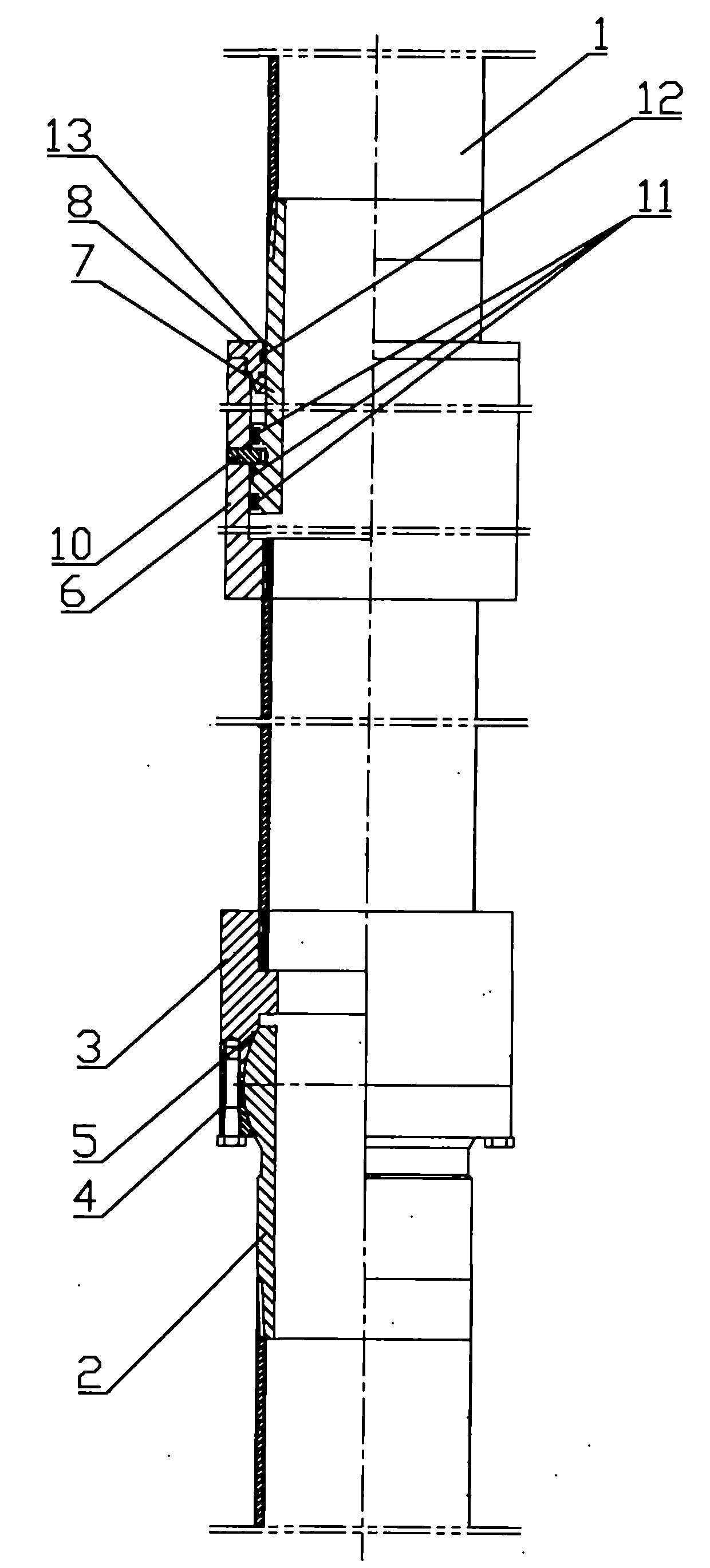

[0021] figure 1 It is a schematic structural diagram of the present invention, as shown in the figure: the ground drilling casing that can prevent mining damage in this embodiment includes a pipe body 1, a deflection joint and an expansion joint, and the pipe body 1 is at least two sections. For example, three sections of pipe body are used. From top to bottom, the first section of pipe body and the second section of pipe body are connected by expansion joints, and the second section of pipe body and the third section of pipe body are connected by deflection joints. According to the analysis results of the displacement, the deflection joint is set at the corresponding depth where the displacement of the rock formation will produce shear and torsion effects on the drilling casing, and the expansion joint is set at the corresponding depth where the displacement of the rock formation will cause tension and compression on the drilling casing. Under the action of the deflection joi...

Embodiment 2

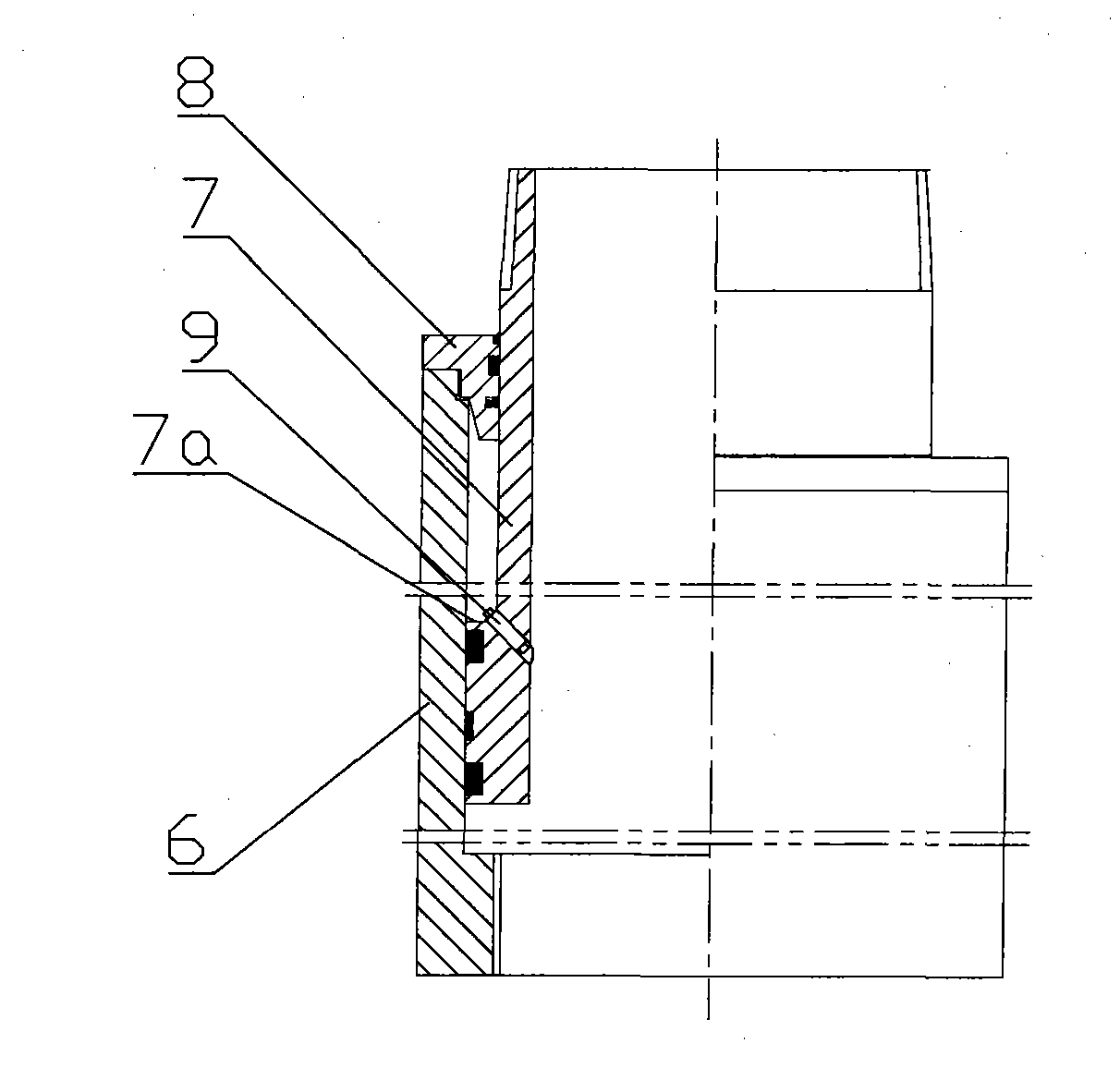

[0027] figure 2 It is a schematic structural diagram of the expansion joint in Embodiment 2 of the present invention, as shown in the figure: in the ground drilling casing that can prevent mining damage in this embodiment, the inner receiving pipe 7 extends into the outer circle of one end of the outer receiving pipe 6 Circumferential steps 7a are arranged on the top, and the expansion joint also includes a guide sleeve 8 that is overlaid on the inner receiving pipe 7 and fixedly connected with the outer receiving pipe 6 in a threaded manner. The guide sleeve 8, the inner wall of the outer receiving pipe 6, and the inner receiving pipe 7. The outer wall and the steps 7a together form a closed space, which is filled with hydraulic medium. A pressure relief valve 9 that communicates with the closed space and the outside world is provided on the wall of the inner receiving pipe 7 to form a locking mechanism. Except for the locking mechanism, the rest are the same structure as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com