Method for detecting and diagnosing faults of intermittent low-speed and heavy-load device

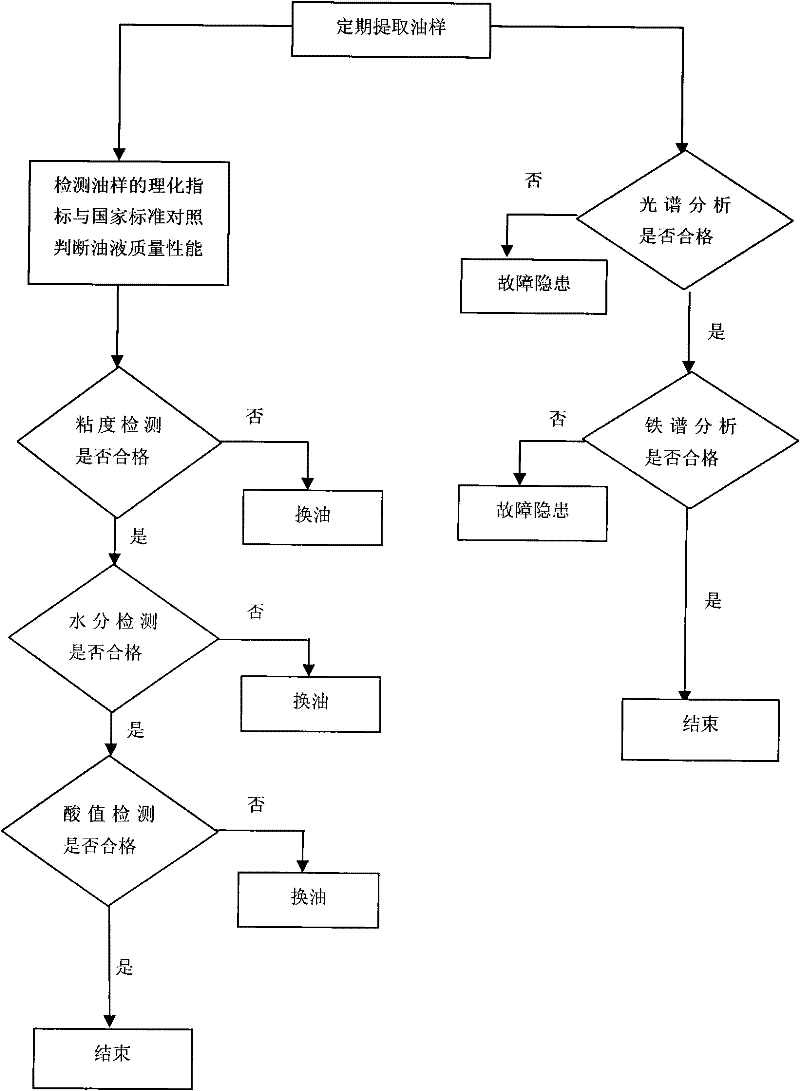

A low-speed heavy-load, equipment failure technology, applied in flow characteristics, measuring devices, instruments, etc., can solve the problems of intermittent low-speed heavy-load equipment failure diagnosis, noise signal interference of fault feature information, and difficulty in extracting weak vibration signals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A large container ship of a shipping company sailing regularly between Shanghai and Japanese ports, when the cargo was loaded and ready to sail, the chief engineer found a large number of large-sized metal abrasive particles on the oil filter, in order to ensure that the ship The safety of the voyage, the captain ordered to stop sailing.

[0026] If the flight fails to depart smoothly, the shipping company may face huge economic losses from three aspects: first, the cargo cannot reach the destination on time, and the carrier will pay huge compensation for breach of contract; second, the ship needs to be sent for inspection immediately to find out the problem Therefore, in addition to paying a lot of maintenance costs, the shipping company will also bear a huge loss of suspension of voyages; Pay an additional charter fee. The above three losses combined are estimated to be as high as several million yuan.

[0027] Because the matter is of great importance, in order to ...

Embodiment 2

[0043] A serious accident of crankshaft locking and piston scuffing happened to an imported diesel engine within ten hours after the overhaul. After contacting the repair unit, it is confirmed that there is no problem with the parts and assembly of the engine. It is further suspected that there may be a problem with the lubrication of the engine: either the wrong oil is used, or the lubricating oil channel is not cleaned when the engine is assembled. However, the repair unit confirmed that neither of the above two situations existed. So the doubts were focused on whether there were impurities entering the lubricating oil passage when the engine was running, but after checking the air filter, it was confirmed that it was working normally, so the doubts were concentrated on the fact that the parts were not cleaned when the engine was assembled. After disassembly and inspection, it was found that the lubricating oil passage of the engine was blocked, and there was black uneven s...

Embodiment 3

[0056] An enterprise newly purchased three air compressors, which were installed and put into use less than 40 hours after they were installed and adjusted, and the failures and shutdowns caused by the stuck pistons occurred one after another. In order to analyze and judge the cause of the failure, the user took 250mL samples from each of the three units and sent them to the oil analysis laboratory. The physical and chemical indicators such as the appearance, viscosity, moisture, acid value and spectral elements of the samples were tested and analyzed. The results are as follows:

[0057] Table 3.1. Summary table of oil product analysis results

[0058] project

new oil

1# unit sample

2# unit sample

3# unit sample

Exterior

Colorless and transparent

dark brown smell

dark brown smell

dark brown smell

Kinematic viscosity at 40°C mm2 / s

98.96

111.6

96.14

131.6

Moisture %

none

0.18

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com