Machine for making bags with oblique zippers

A bag-making machine and zipper technology, applied in envelope/bag manufacturing machinery, paper/cardboard containers, clothing, etc., can solve the problems of low production efficiency, difficulty in controlling hygienic quality and product quality of slanted zipper bags, and flat-mouth zipper bag making machines It is not suitable for the production of slanted zipper bags, etc., to achieve the effect of improving production quality and hygiene quality, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

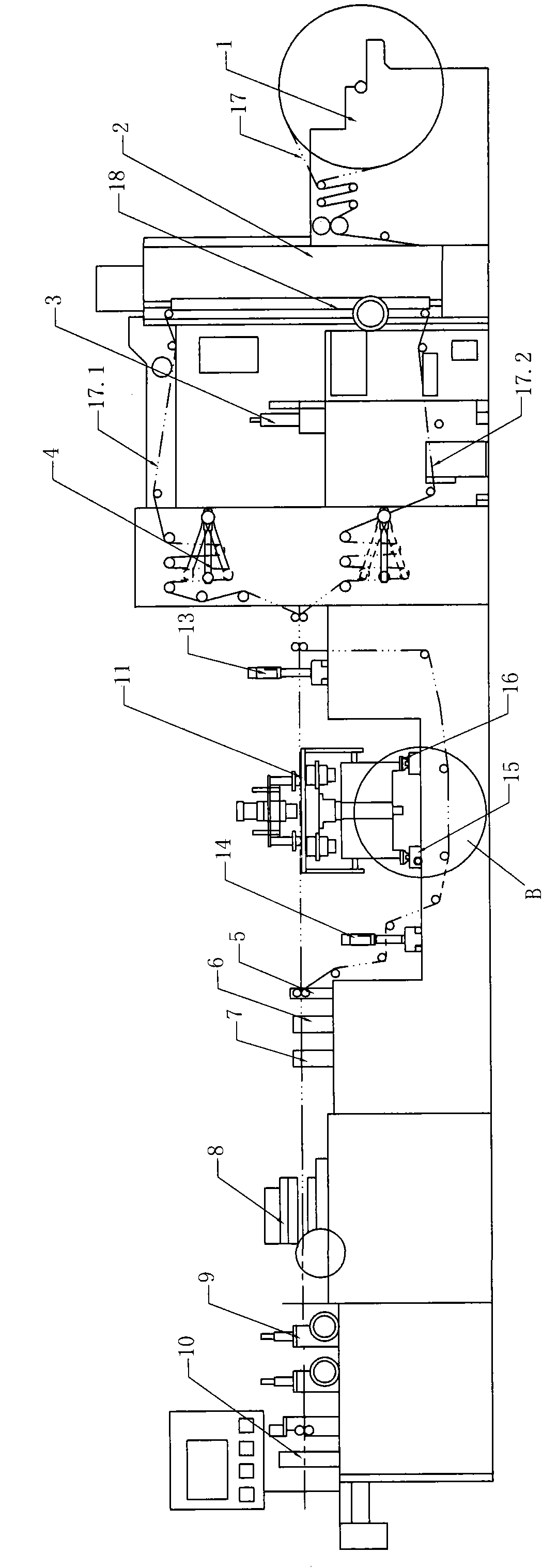

[0018] Such as figure 1 As shown, a slanted zipper bag making machine includes a feeding device 1, a deviation correcting device 2, a half-cutting device 3, a stand-up pouch punching device 18, a tension frame 4, a overlapping device 5, a heat sealing device 6, and a cooling device 7 , vertical sealing device 8, horizontal sealing device 9 and cutter 10; it is characterized in that a zipper positioning installation device 11 is provided between the tension frame 4 and the heat sealing device 6; a film punching is provided at the front end of the zipper positioning installation device 11 machine 13, the rear end of the zipper positioning installation device 11 is provided with a lower film punching machine 14; Above, the longitudinal moving device 16 is installed and fixed on the lateral moving device 15 .

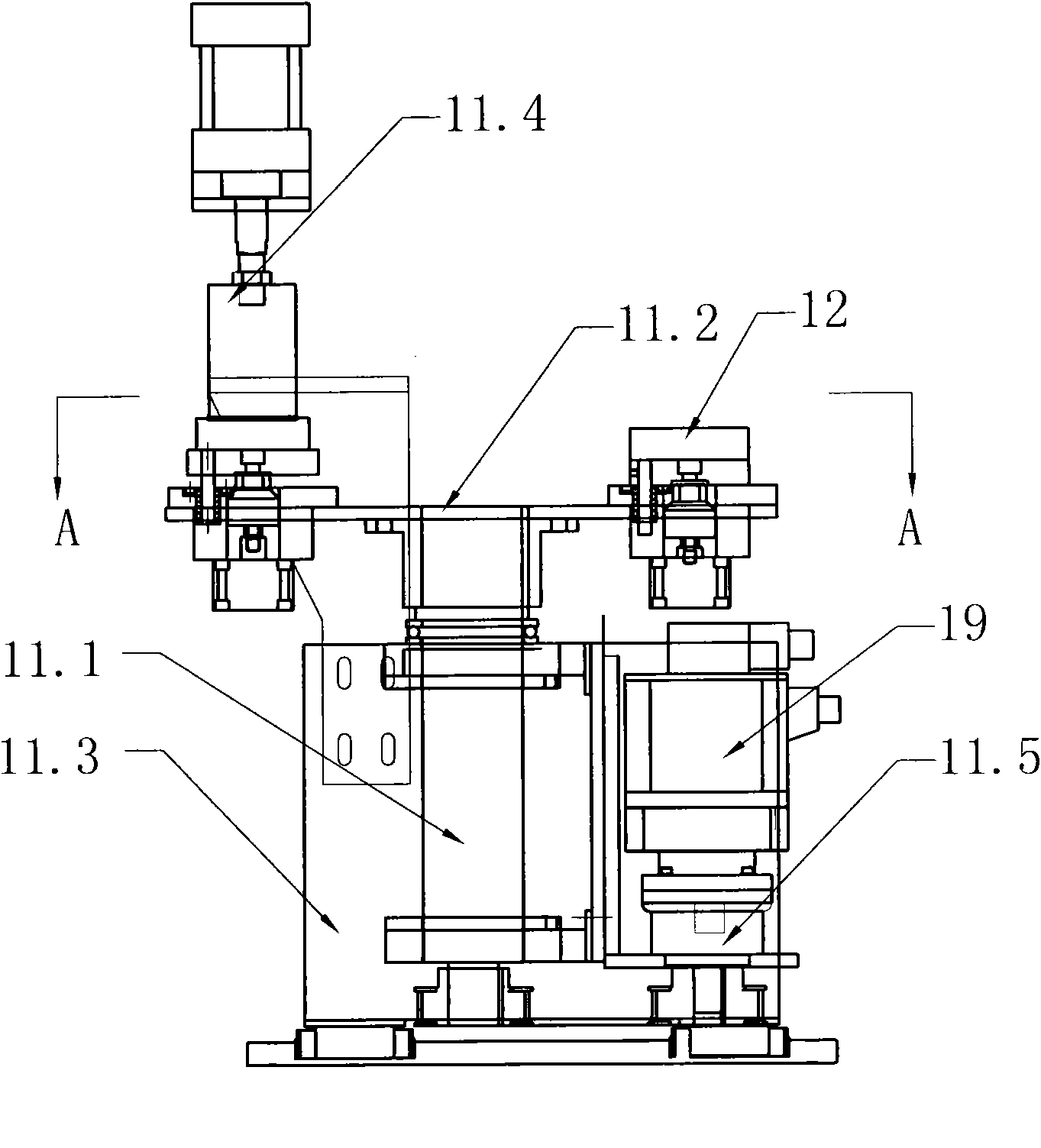

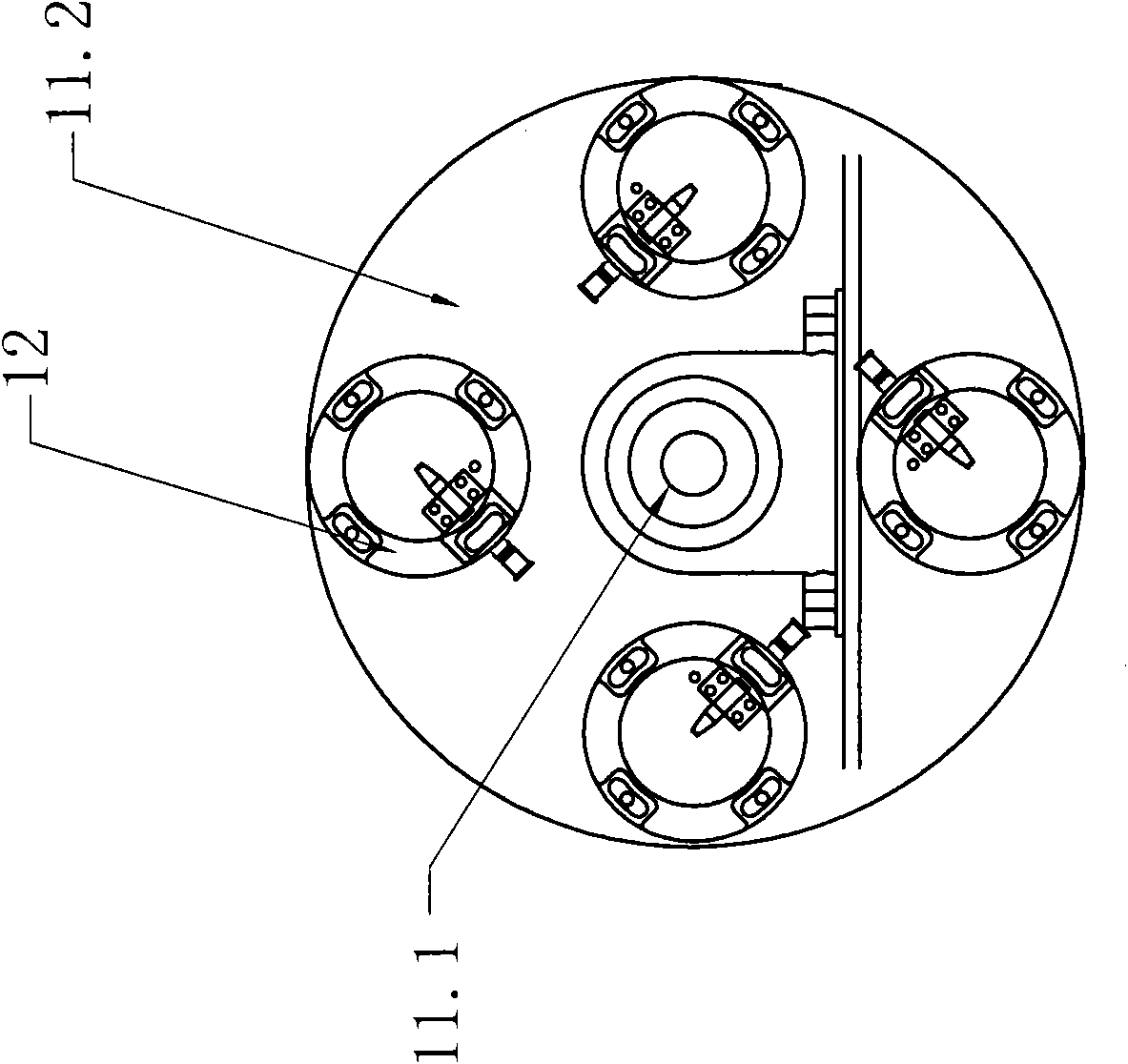

[0019] Such as figure 2 and image 3 As shown, the zipper positioning installation device 11 includes: a rotating shaft 11.1, a rotating disk 11.2, a bracket 11.3, a sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com