Permanent pressure meter testing technique for coal bed gas observation well

The technology of one-type pressure gauge and testing technology, which is applied in the field of permanent pressure gauge testing of coalbed methane observation wells, can solve problems such as difficult coalbed methane reservoirs, and achieve the effect of improving data accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

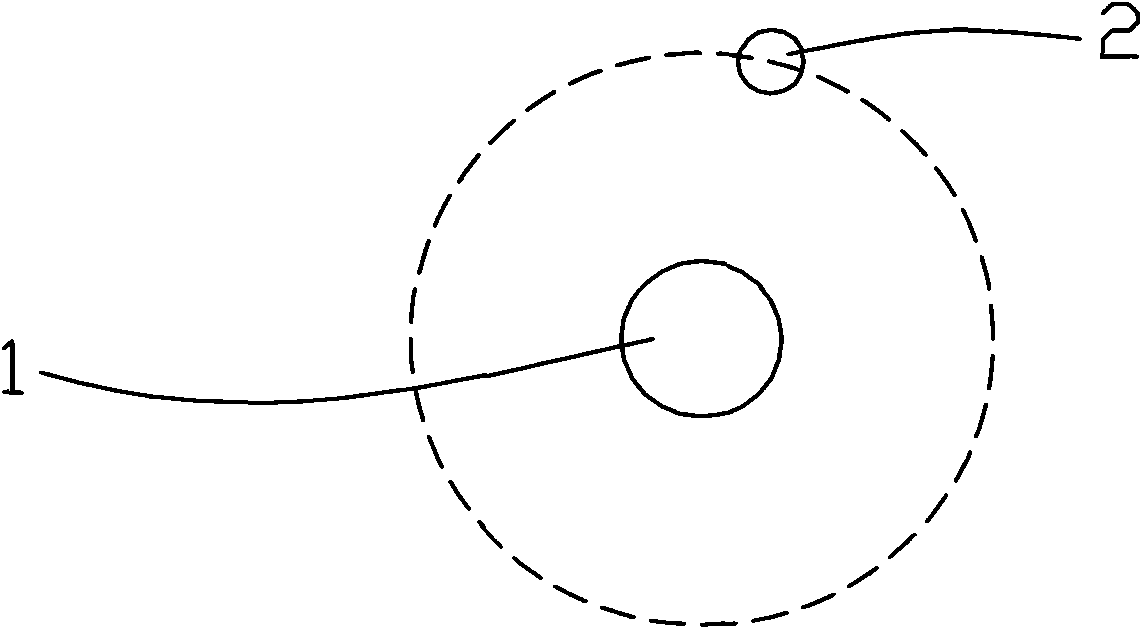

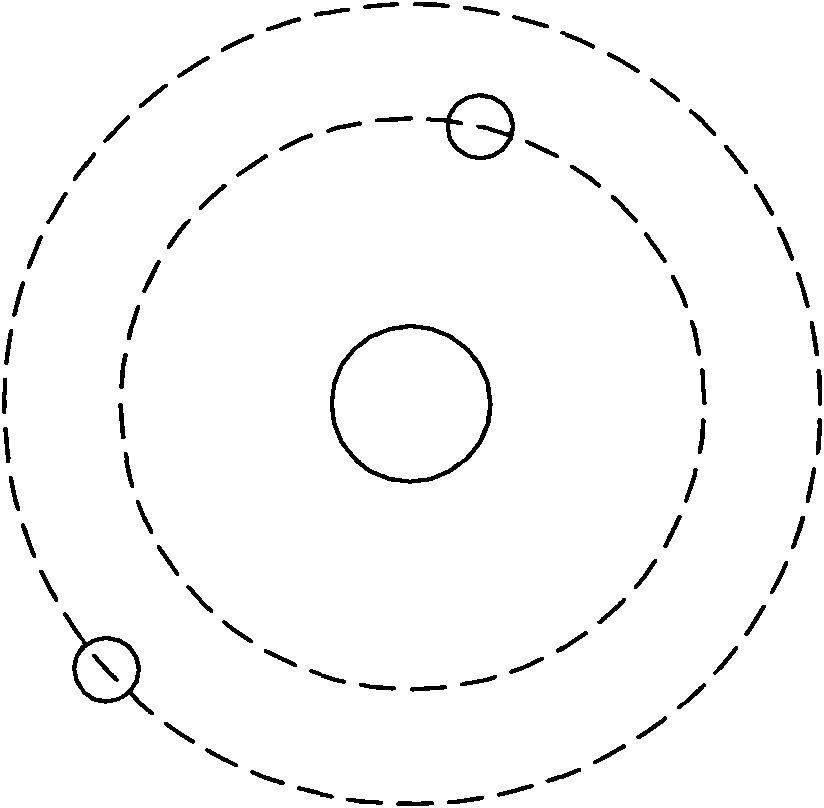

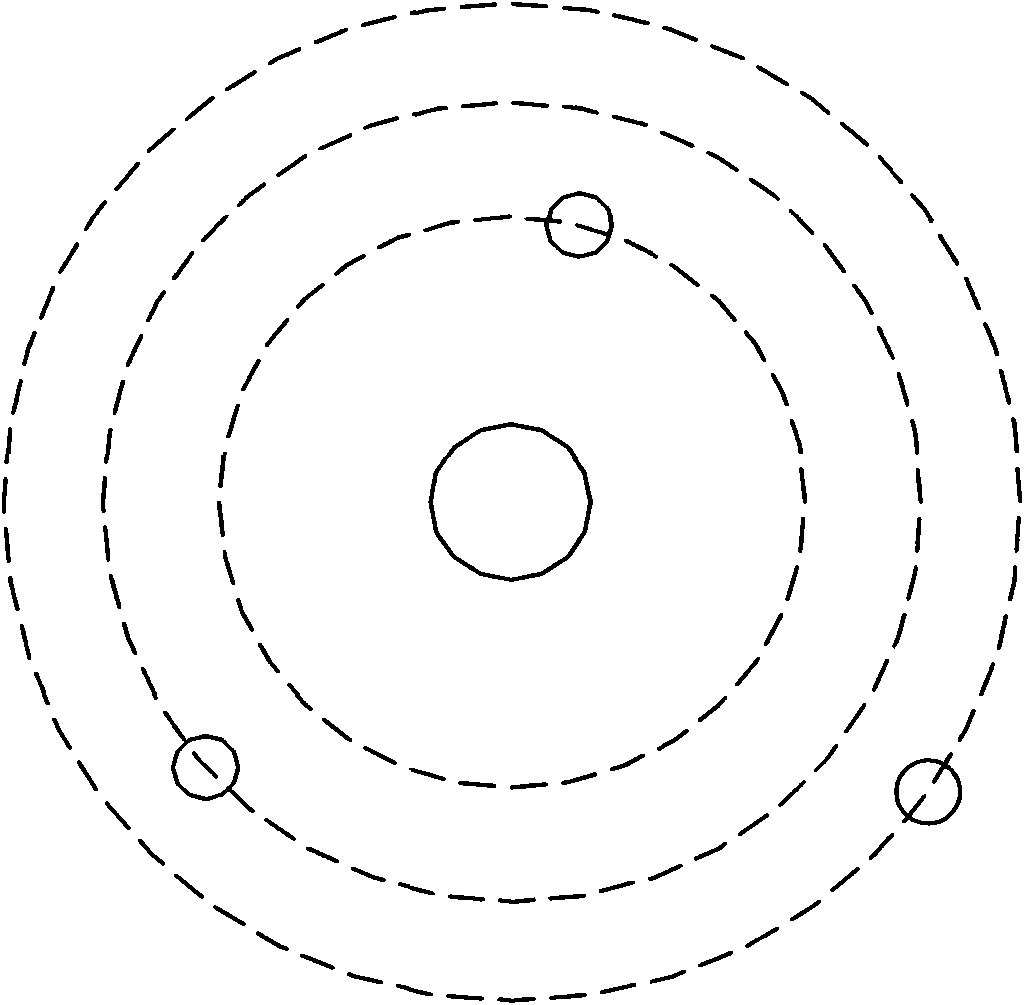

[0019] Such as Figure 1 to Figure 5 As shown, a permanent pressure gauge testing technology for coalbed methane observation wells of the present invention is specifically: one or several observation wells 2 are set within a set distance around the coalbed methane well 1, and part of the observation wells can be partially observed according to the needs of actual measurement. The distance between the well 2 and the coalbed methane well 1 is set to be the same, and the distance between some observation wells 2 and the coalbed methane well 1 is set to be different, or the distances between each observation well 2 and the coalbed methane well 1 are all different. By setting different distances, the pressure at different locations can be obtained, so as to determine the pressure distribution around the coalbed methane well.

[0020] Permanent electronic pressure gauges are lowered in the observation well 2, and non-disturbance in-situ testing is carried out through the permanent e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com