Overlarge type ring rolling machine

A super-large ring rolling machine technology, applied in the direction of metal rolling, etc., can solve the problems of large deformation of the suspended side of each roll, high equipment capacity requirements, high manufacturing cost of forgings, etc., to achieve large rolling capacity, large weight, and easy processing high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

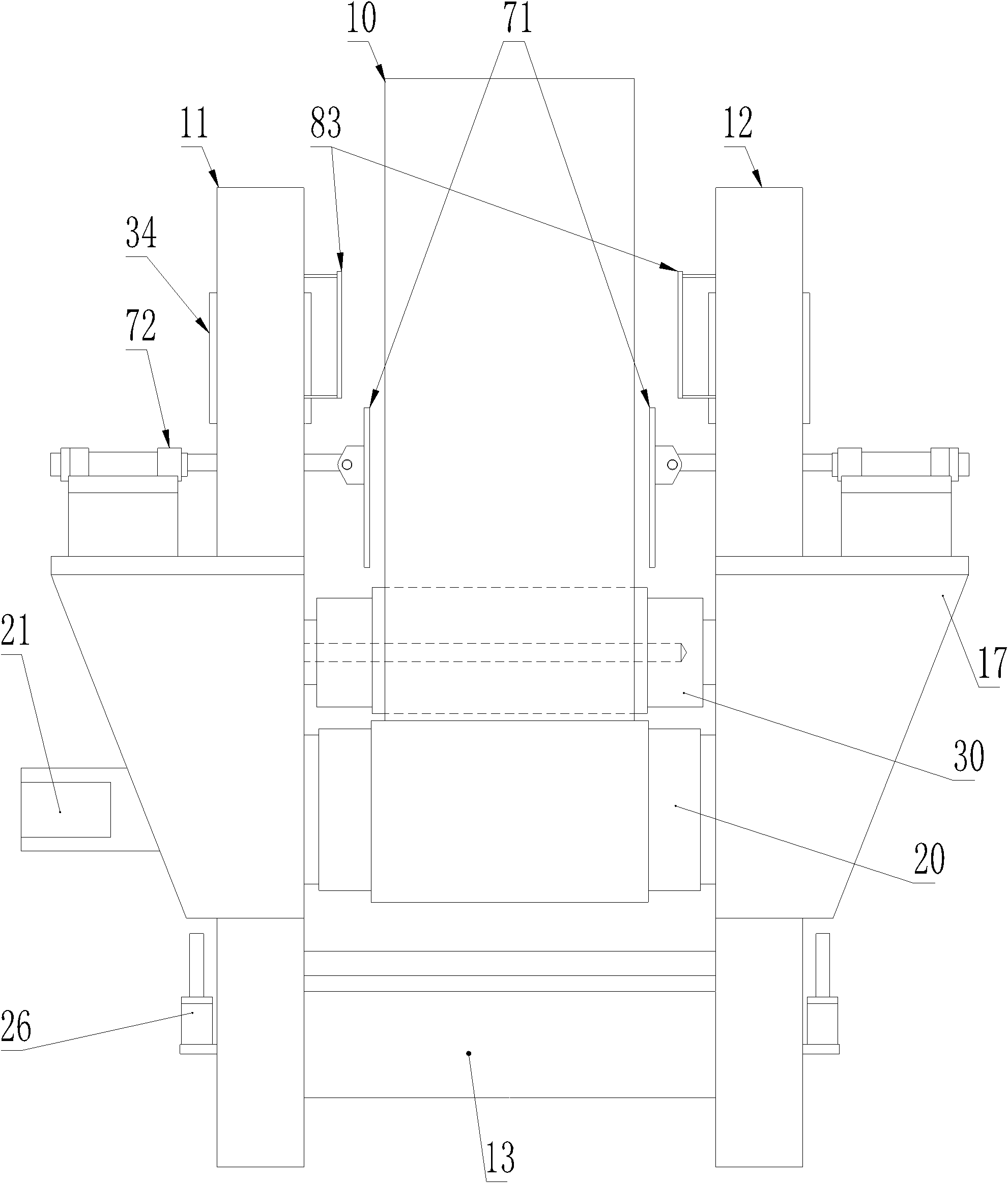

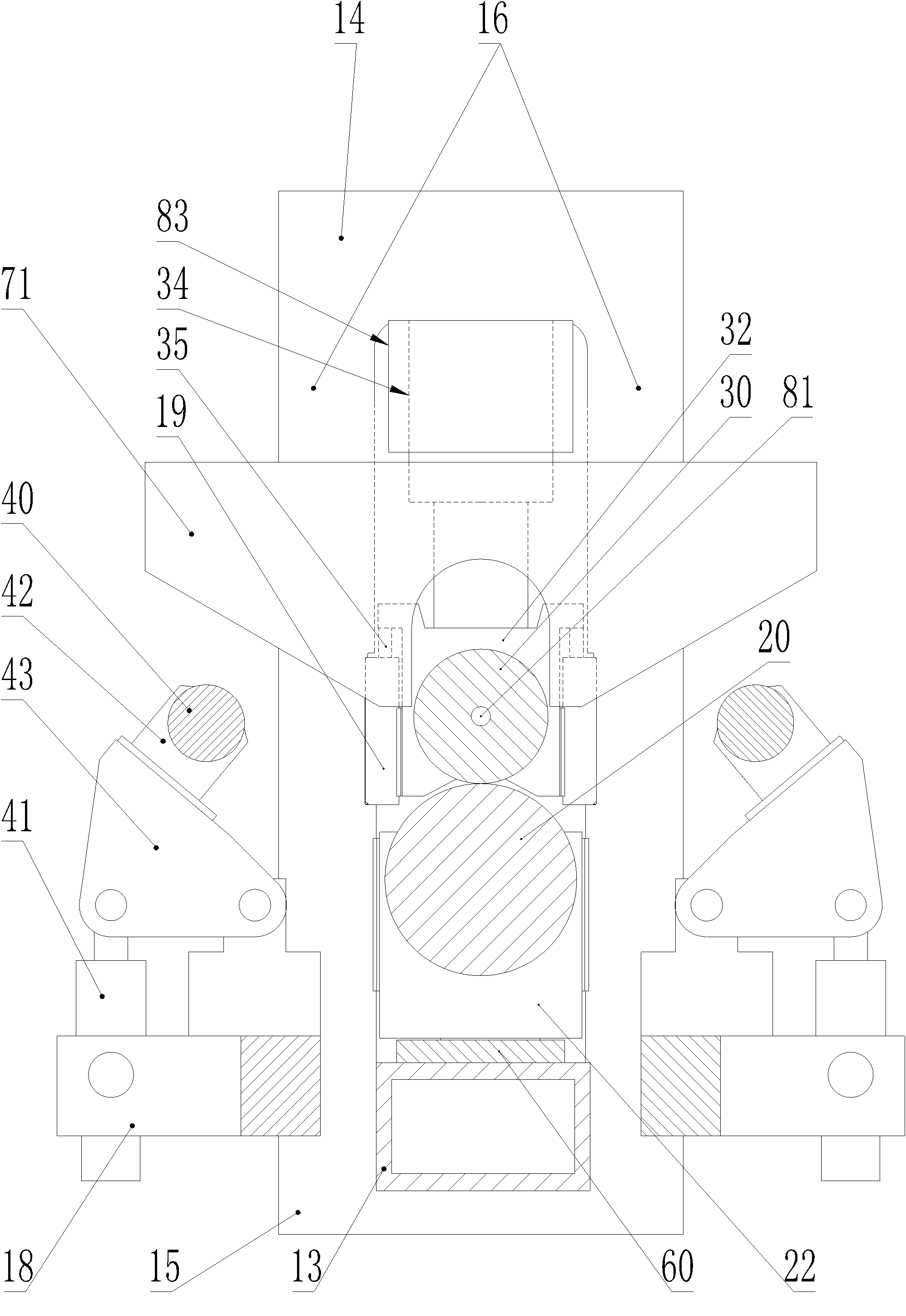

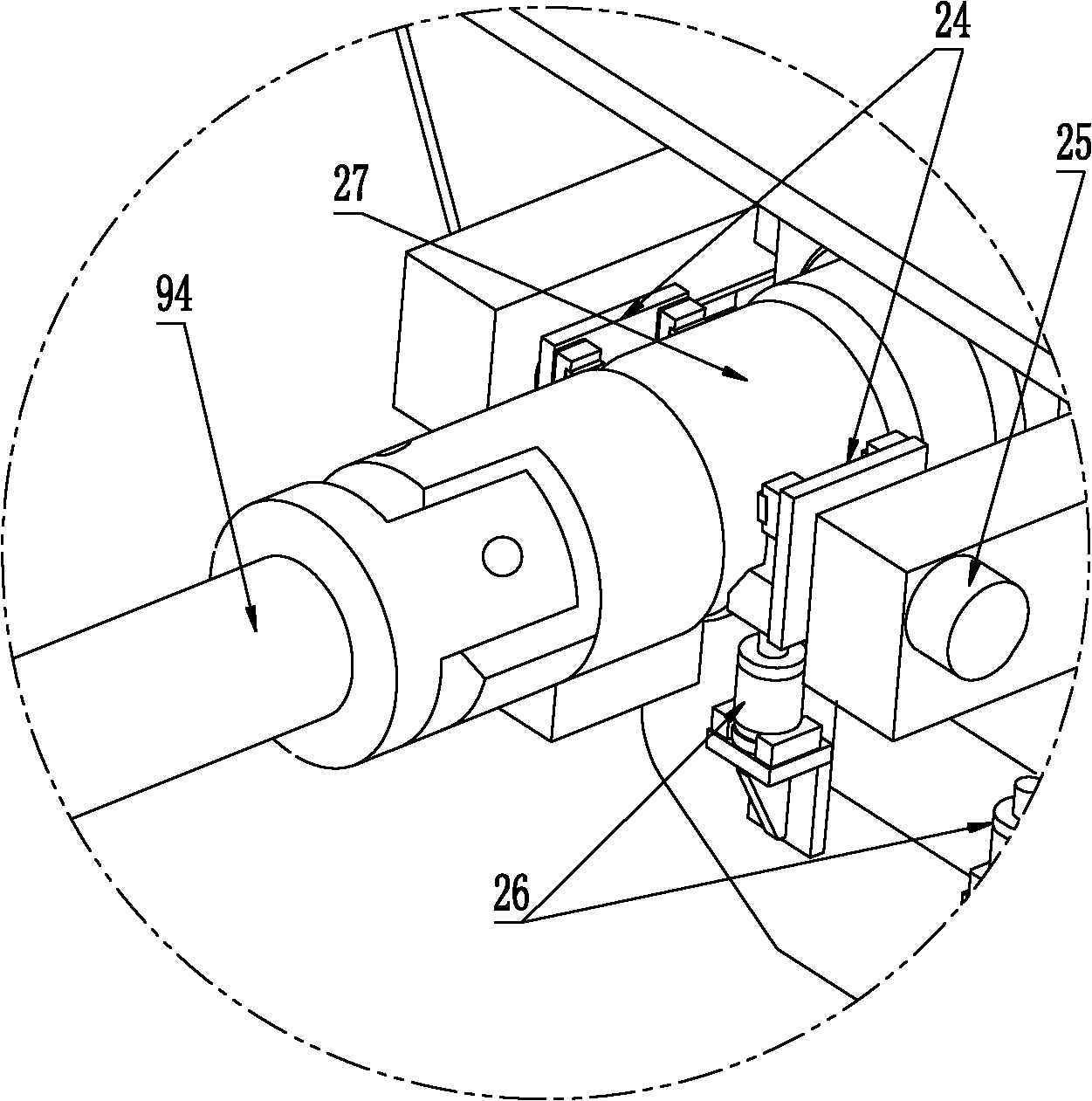

[0059] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 As shown, the super large ring rolling machine has a design rolling force of 5000-7000 tons, a maximum ring diameter of 8000-9000mm, and a maximum ring height of 3000-3800mm. Frame is the open frame that is formed by the bottom beam 13 between the drive side frame 11 and the operation side frame 12 that are arranged vertically and oppositely, and the bottom beam 13 between the drive side frame 11 and the operation side frame 12 bottoms. Both the drive side frame 11 and the operation side frame 12 are archway-type integrally enclosed casting frames composed of top beams 14, bottom beams 15, and upright columns 16 on both sides, and are surrounded by top beams 14, bottom beams 15, and upright columns 16. Forming the frame window, the strengthening support on the outside of the transmission side frame 11 and the operation side frame 12 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com