Clamp for instrumented indentation testing

An instrumented press-in and fixture technology, which is applied in the direction of instruments, scientific instruments, and measuring devices, can solve problems affecting the stability of indentation depth measurement, unsmooth loading and unloading curves, and sudden changes in displacement measurement. It achieves compact structure, Low cost, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

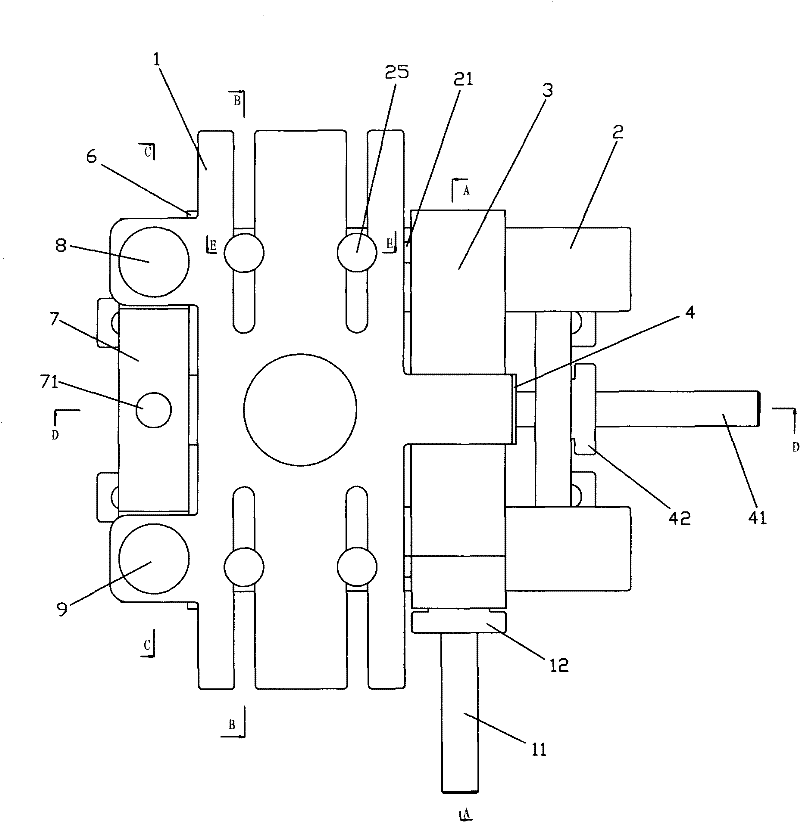

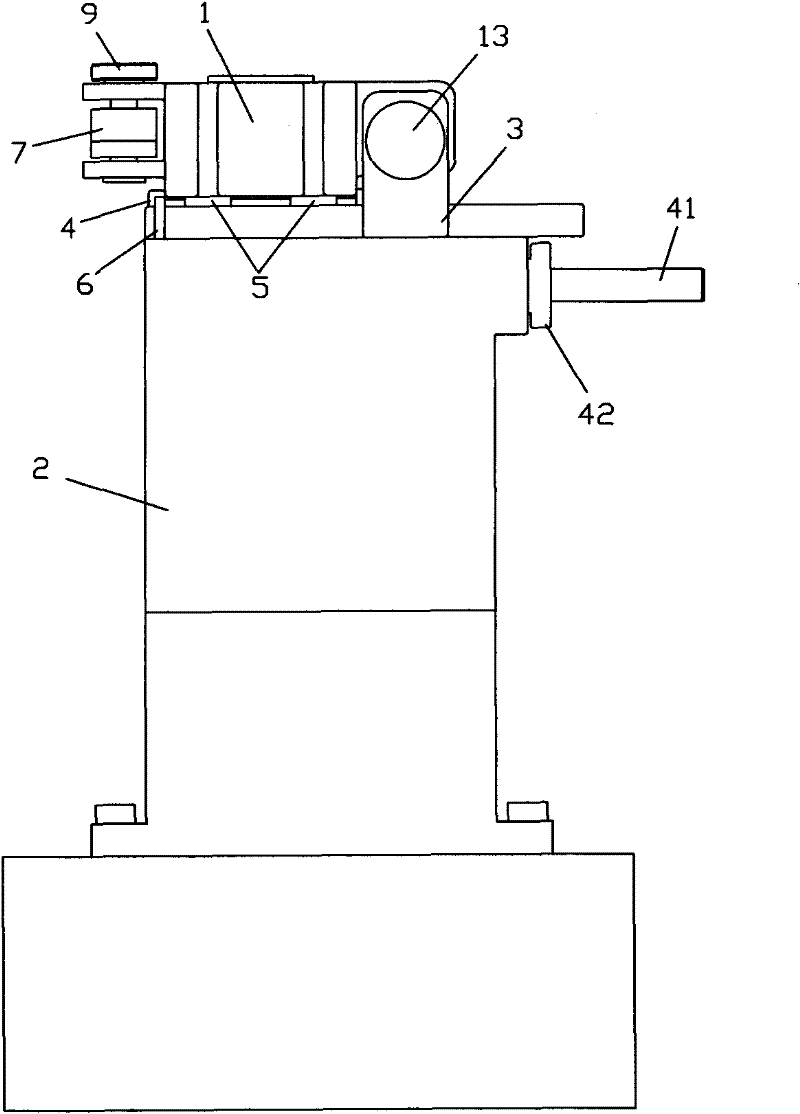

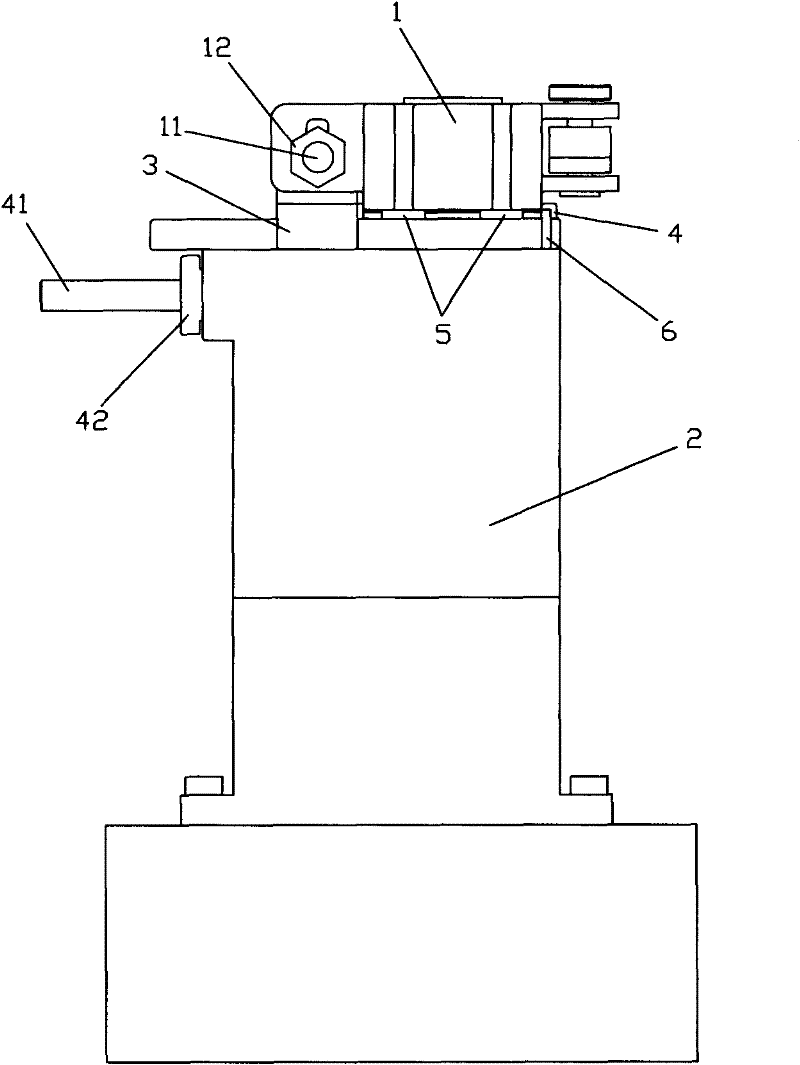

[0047] Such as Figure 1-6 As shown, the fixture of the instrumented press-in test of the present invention includes a sample stage 1 and a base 2. The sample stage 1 is erected on the base 2 through a mobile support mechanism. The mobile support mechanism includes a pulling plate 3, an intermediate plate 4 and a supporting plate 6 , the pulling plate 3, the middle plate 4 and the supporting plate 6 can be integrally formed or separately arranged, the pulling plate 3 and the supporting plate 6 are erected on the base 2, the middle plate 4 is arranged on the pulling plate 3 and the supporting plate 6, and the backing plate 5 Clamped on the middle plate 4, the sample stage 1 is placed on the backing plate 5, and the sample stage 1 can move laterally with the mobile support mechanism, and can also move longitudinally relative to the mobile support mechanism. Such as Figure 9-18As shown, the base 2 is provided with two guide rails 22, 23, and the bottom of the pulling plate 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com