Bidirectional deformation film type oil injection quantification throttling mechanism

A throttling mechanism and deformation technology, applied in the direction of diaphragm, diaphragm valve, mechanical equipment, etc., can solve the problems of short battery life, inaccurate control of fuel injection, and high control power consumption, so as to improve accuracy and control power consumption. The effect of reducing and reducing control power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

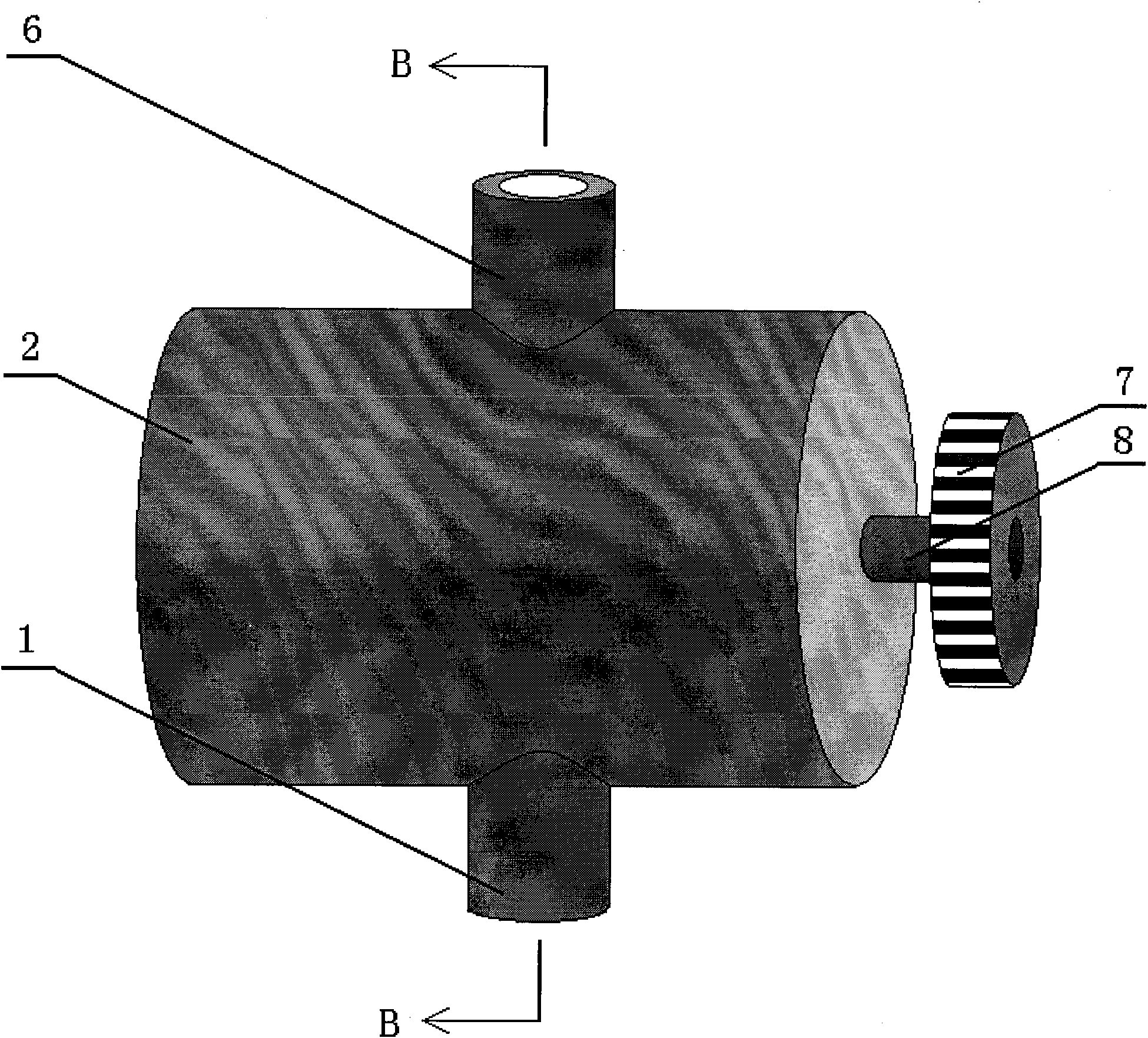

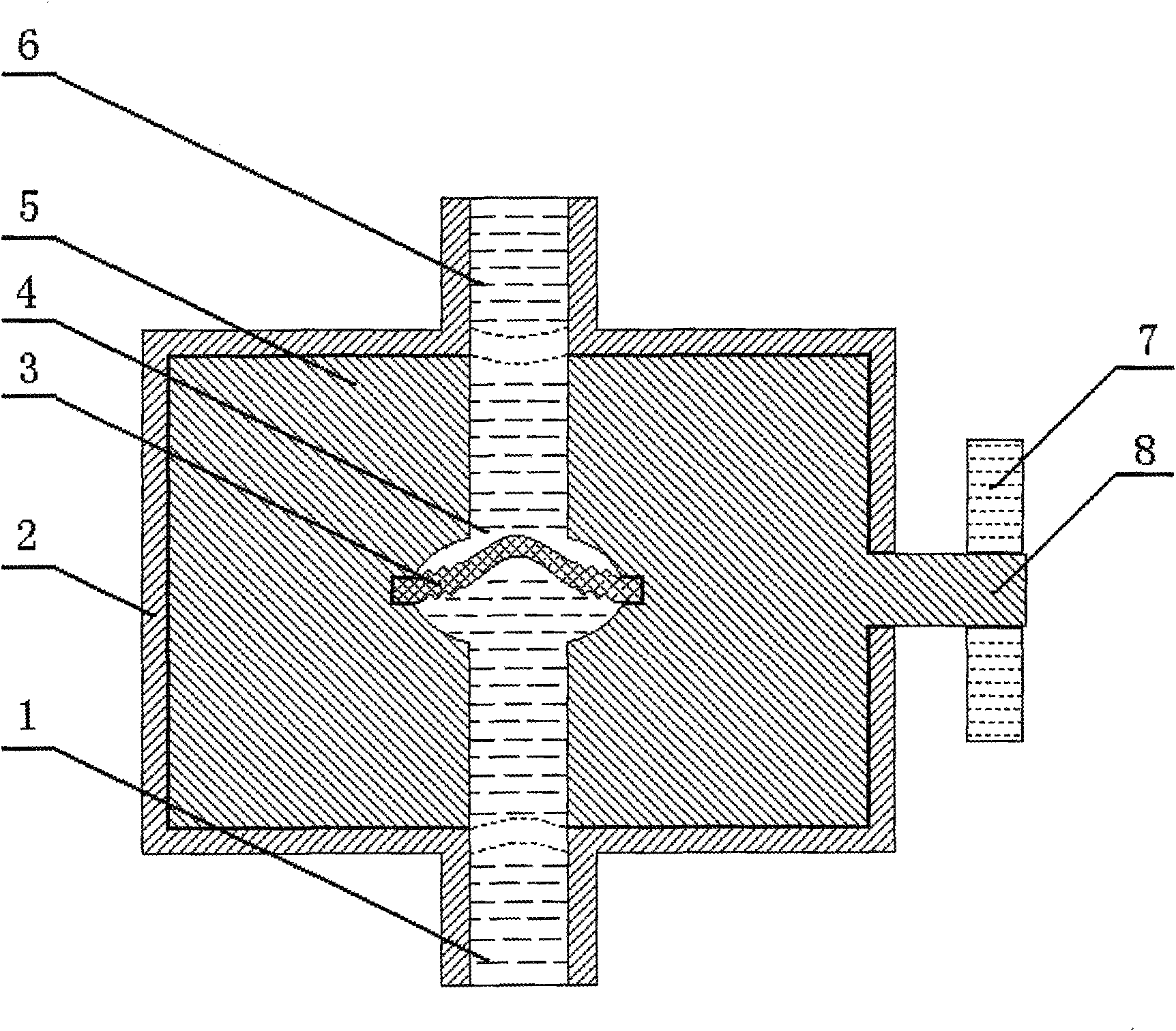

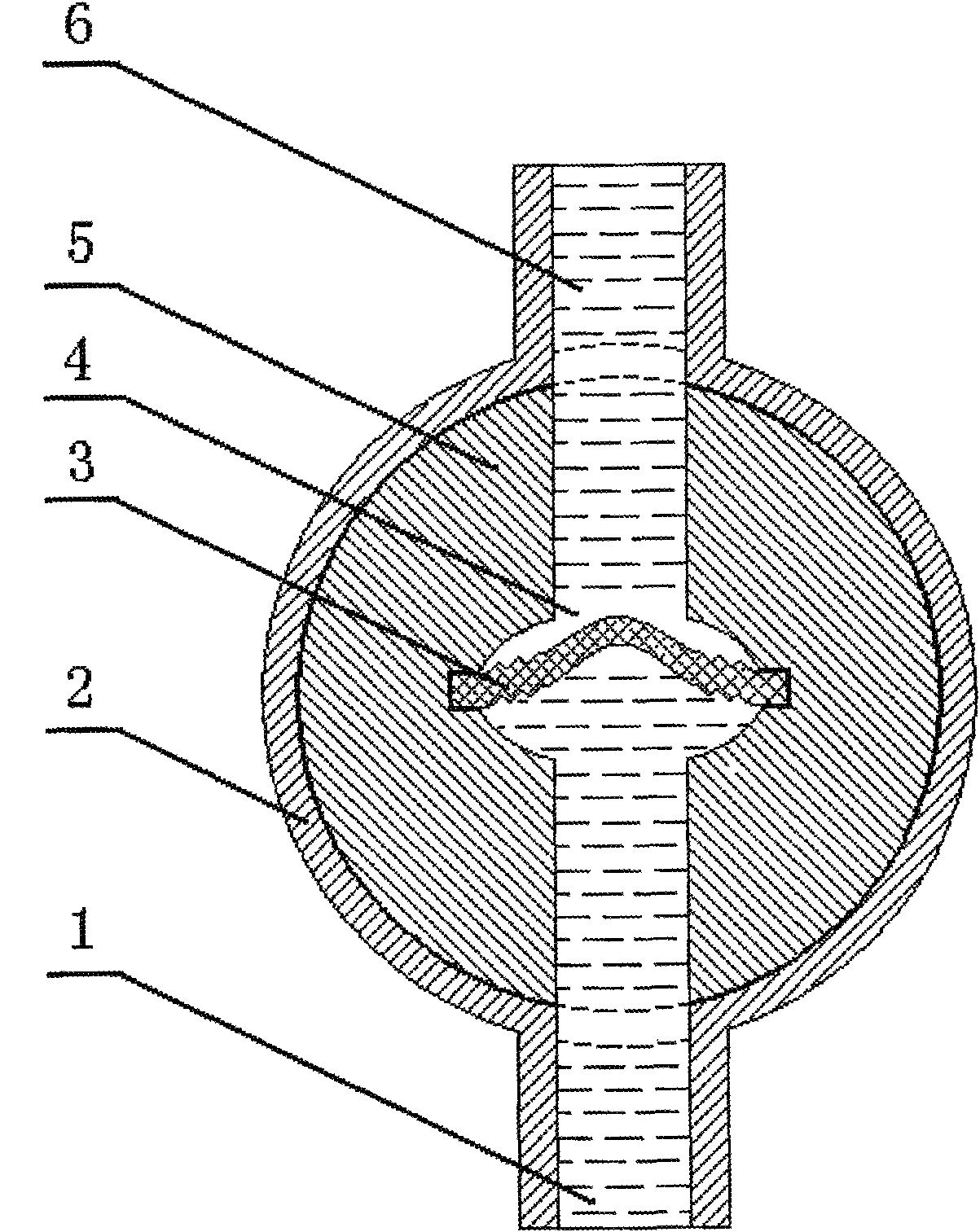

[0012] A throttling rotor (5) is installed in the outer cylinder (2) of the throttling mechanism, and the throttling rotor (5) can rotate in the outer cylinder (2) of the throttling mechanism and has a sealing function at all interfaces. The throttling rotor (5) is provided with a throttling fluidization cavity (4), and a throttling deformation film (3) is installed in the throttling fluidization cavity (4). ) occurs longitudinal elastic deformation; the throttling rotor (5) is provided with a rotor shaft handle (8), and the rotor shaft handle (8) is equipped with a rotor gear (7); when the control driving force passes through the rotor gear (7), the rotor shaft The handle (8) drives the throttling rotor (5) to rotate in the outer cylinder (2) of the throttling mechanism, and when the upper opening of the throttling fluidization chamber (4) is aligned with the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com