Hinge and mounting method of hinge and door

A hinge and mounting screw technology, which is applied to hinges with pins, arrangement of wing sashes, door/window accessories, etc., can solve problems such as unsightly tenon positions, avoid cracking of textures, facilitate installation and simple hinge structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

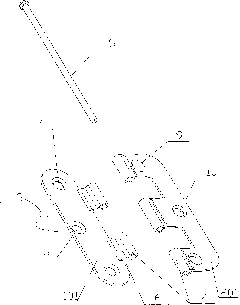

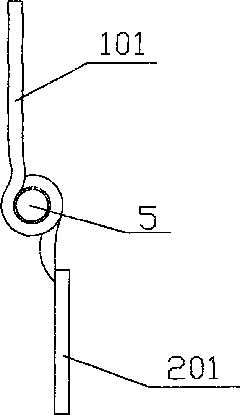

[0022] A kind of hinge that can install the door as a right-handed or left-handed door. The upper surface of the door hinge 101 installed on the door is provided with an arched bridge 6 connected with the roll circle 4 of the door hinge. See Figure 4 shown; see figure 1 , figure 2 , image 3 As shown, the using method of the door frame hinge 201 installed on the door frame is the same as the current conventional door frame hinge; the door hinge and the door frame hinge are respectively provided with mounting screw holes 3 . Axle core 5 is inserted in the rolling circle and these two parts of door hinge and door frame hinge are connected, and door hinge and door frame hinge can be rotated mutually. The hinge in this invention has 1 or more tooth positions, without limitation.

[0023] see figure 2 As shown, the mounting screw holes of the door hinge leaf installed on the door limit have a first mounting screw hole 7 and a second mounting screw hole 8; The first mounting...

Embodiment 2

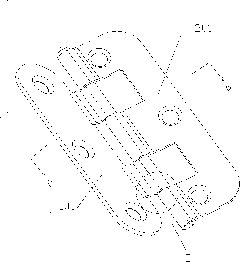

[0029] This embodiment 2 changes the structure of the hinge door frame hinge on the basis of embodiment 1. The difference between embodiment 2 and embodiment 1 is: the door frame hinge 202 and door hinge 102 of embodiment 2 The axis is symmetrical to the line of symmetry and is mirror-symmetrical, see Image 6 shown. This kind of mirror symmetry makes the hinge of this invention suitable for any interchangeable installation of the door hinge and door frame hinge without changing the tenon position of the door edge. Or the effect of right loading.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com