Movable pre-stretching device for chain

A chain and pre-tensioning technology, used in metal chains, wire tensioning appliances, manufacturing tools, etc., can solve the problems of unstable pre-tension value and low processing efficiency, and achieve the effect of stable pre-tension value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

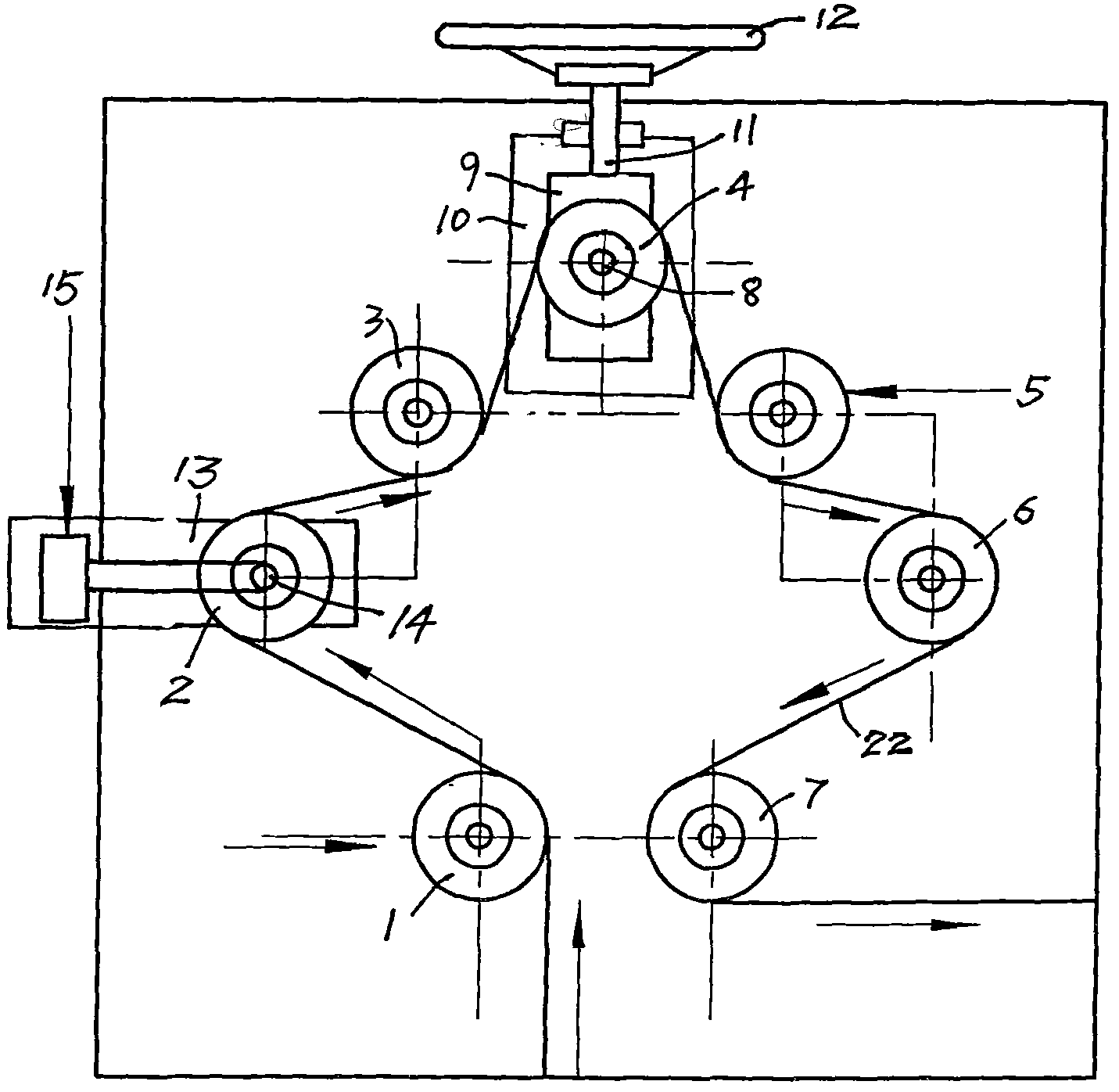

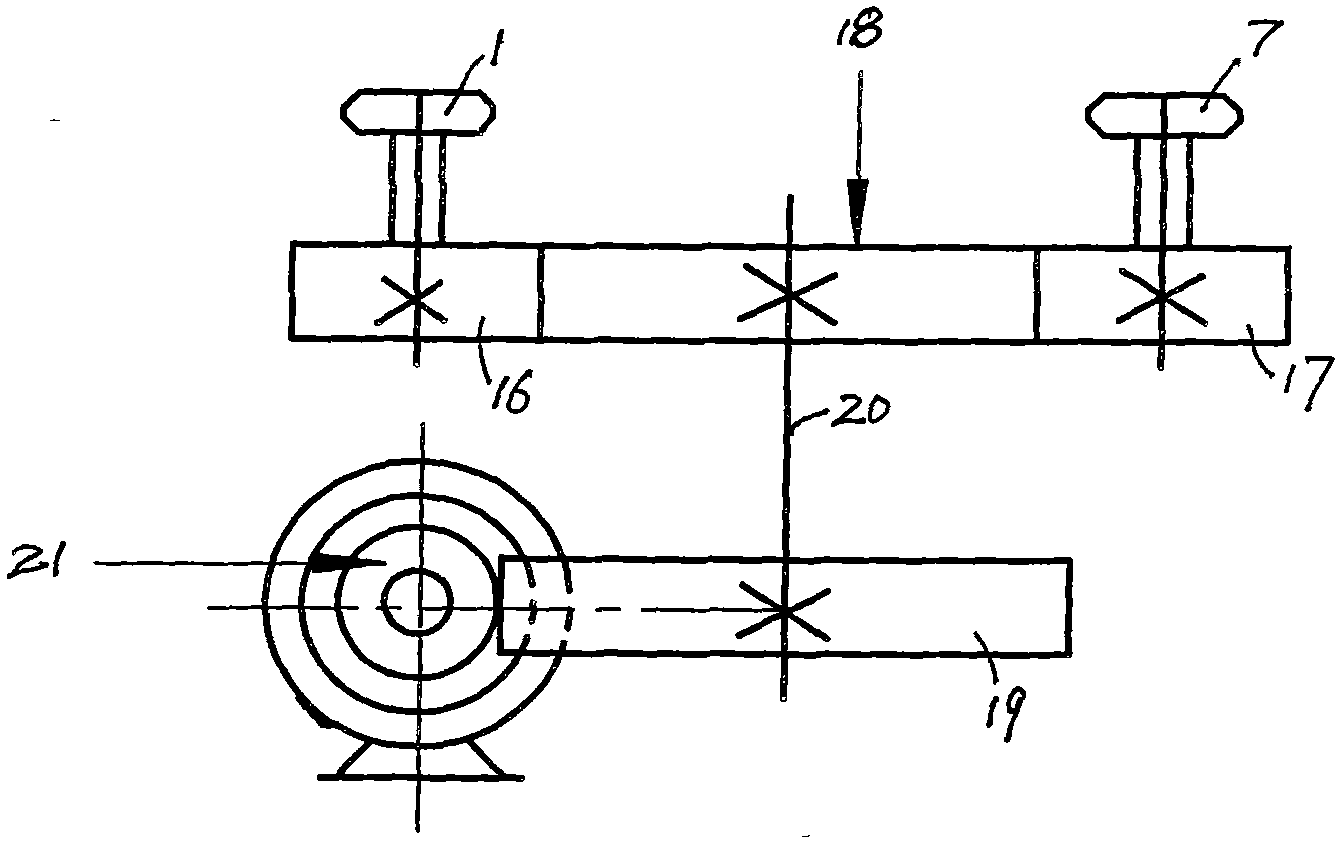

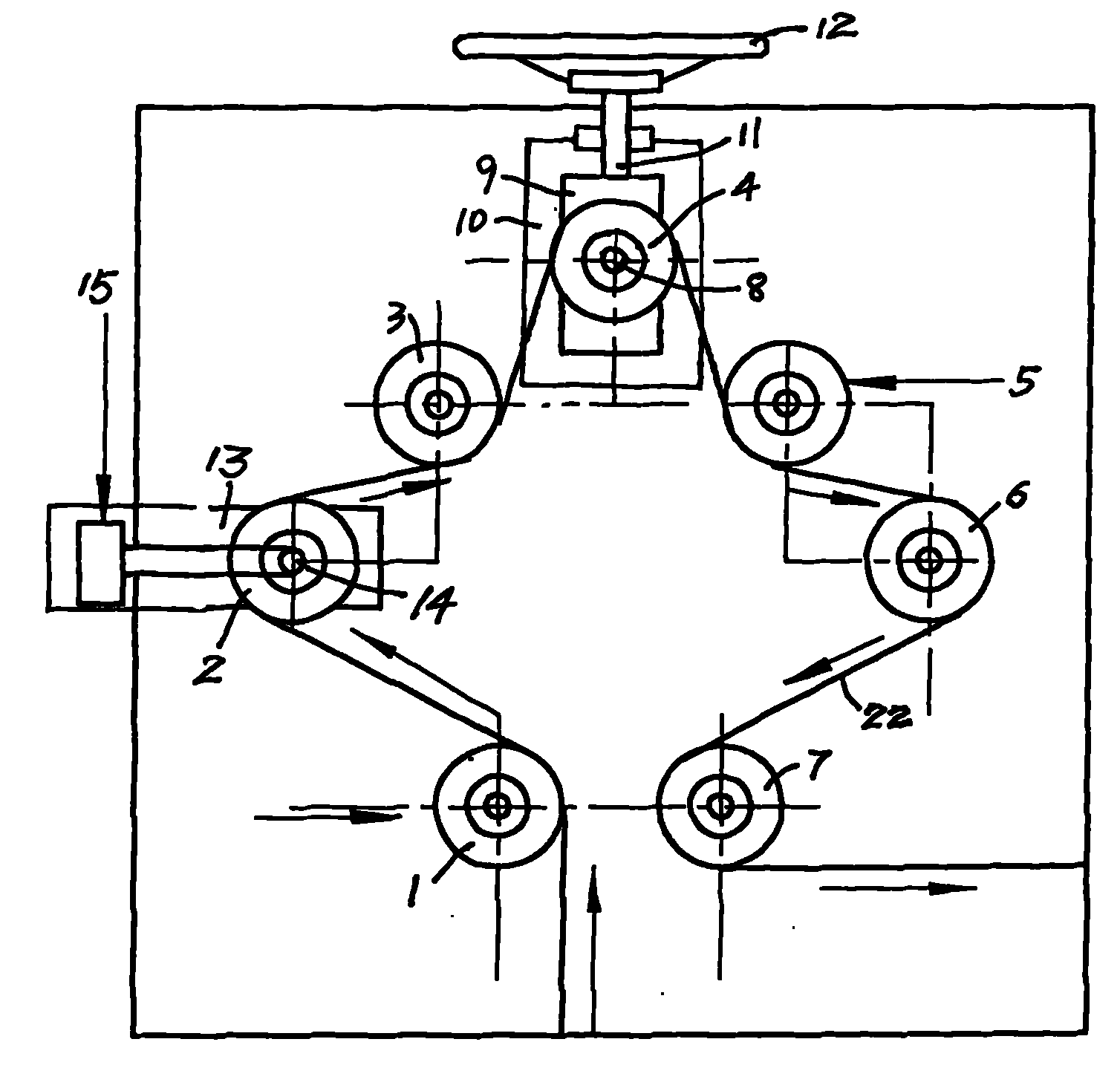

[0012] See figure 1 The shown chain dynamic pre-tensioning device includes a chain feed sprocket 1, a weighing sprocket 2, a first driven sprocket 3, a booster sprocket 4, and a second driven chain for bypassing the chain 22 in turn. Wheel 5, transition sprocket 6, chain-out sprocket 7.

[0013] The booster sprocket shaft 8 is arranged on the slide block 9 that can slide radially of the booster sprocket relative to the booster sprocket seat, and the end of the screw rod 11 that is threadedly connected with the booster sprocket seat 10 is hinged on the slide block , the other end of screw rod 11 is fixed runner 12. By turning the screw rod, the slide block moves along the radial direction of the booster sprocket together with the booster sprocket shaft and the booster sprocket on it, thereby changing the value of the pre-tensioning force.

[0014] The weighing sprocket shaft 14 of the suit weighing sprocket 2 is slidably arranged on the weighing sprocket seat 13, and the weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com