Preparation method of octahedron nickel nano micro-material

An octahedral, nano-micro technology, applied in the field of generating octahedral nickel nano-micro materials by thermal decomposition-reduction process, can solve the problems of complex process, application limitation, low efficiency, etc., and achieve high purity, wide application and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

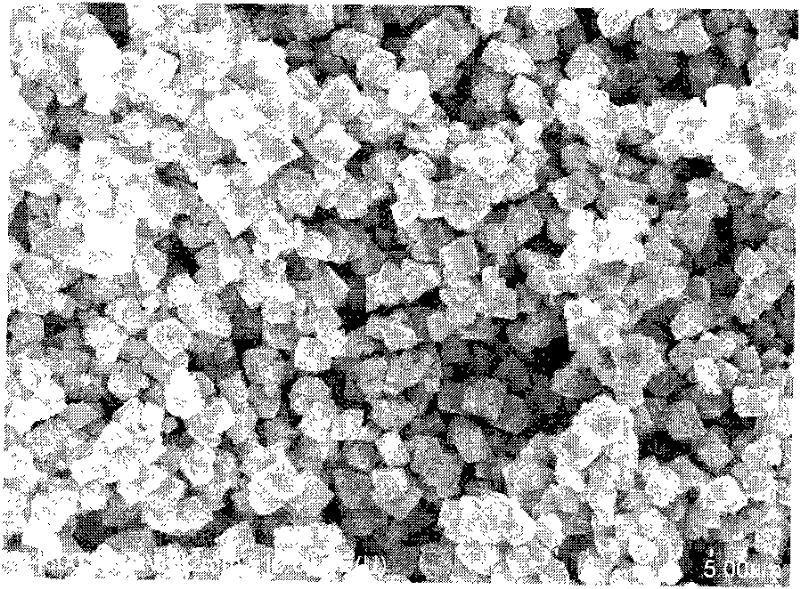

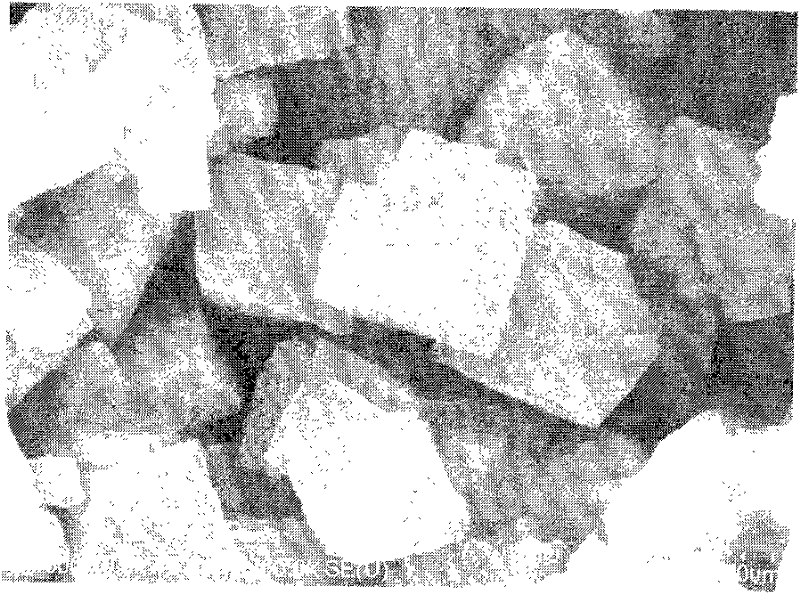

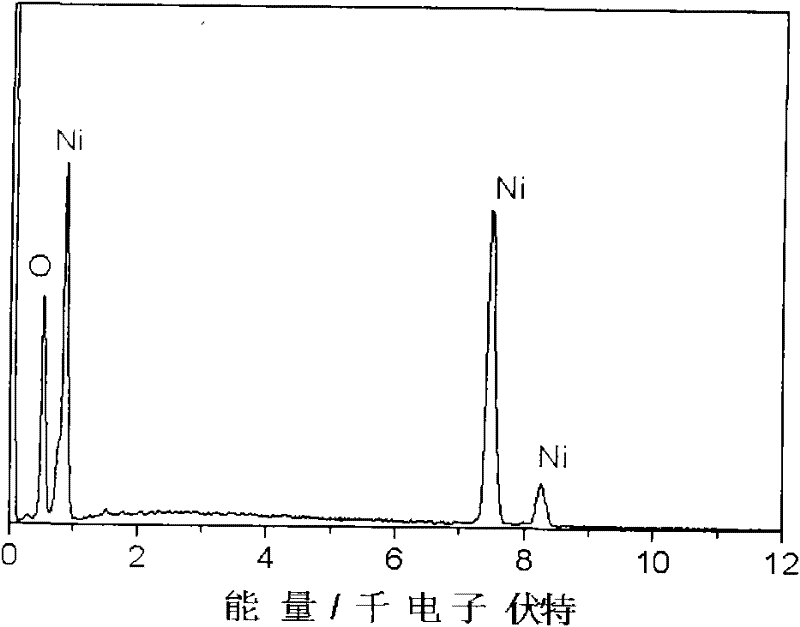

[0035] Place a 4cm×6cm×1.5cm ceramic ark containing 10 grams of nickel nitrate in a box-type high-temperature furnace, heat at 300°C for 30 minutes, and after cooling with the furnace, wash and filter the gray-black substance generated by the reaction, and use deionized Washed several times with water and ethanol, then dried in an oven at 80°C for 12 hours. The morphology of the obtained product is as figure 1 and figure 2 As shown, the element composition ( image 3 ) and phase analysis (see Figure 4 ) surface of the product is octahedral NiO nanoparticles.

Embodiment 2

[0037] Adopt the technique among the embodiment 1, when the reaction time is 5 hours, as Figure 5 and Figure 6 As shown, octahedral NiO nanoparticles can also be obtained.

Embodiment 3

[0039] Adopt the technique among the embodiment 1, when thermal decomposition temperature is 500 ℃, the reaction time is 5 hours, as Figure 7 As shown, octahedral NiO nanoparticles can also be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com