Advanced strap pipe wrench for driving an object having a generally cylindrical shape

A pipe wrench, object technology, applied in application, wrench, liquid handling, etc., can solve the problem of time-consuming strap adjustment stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

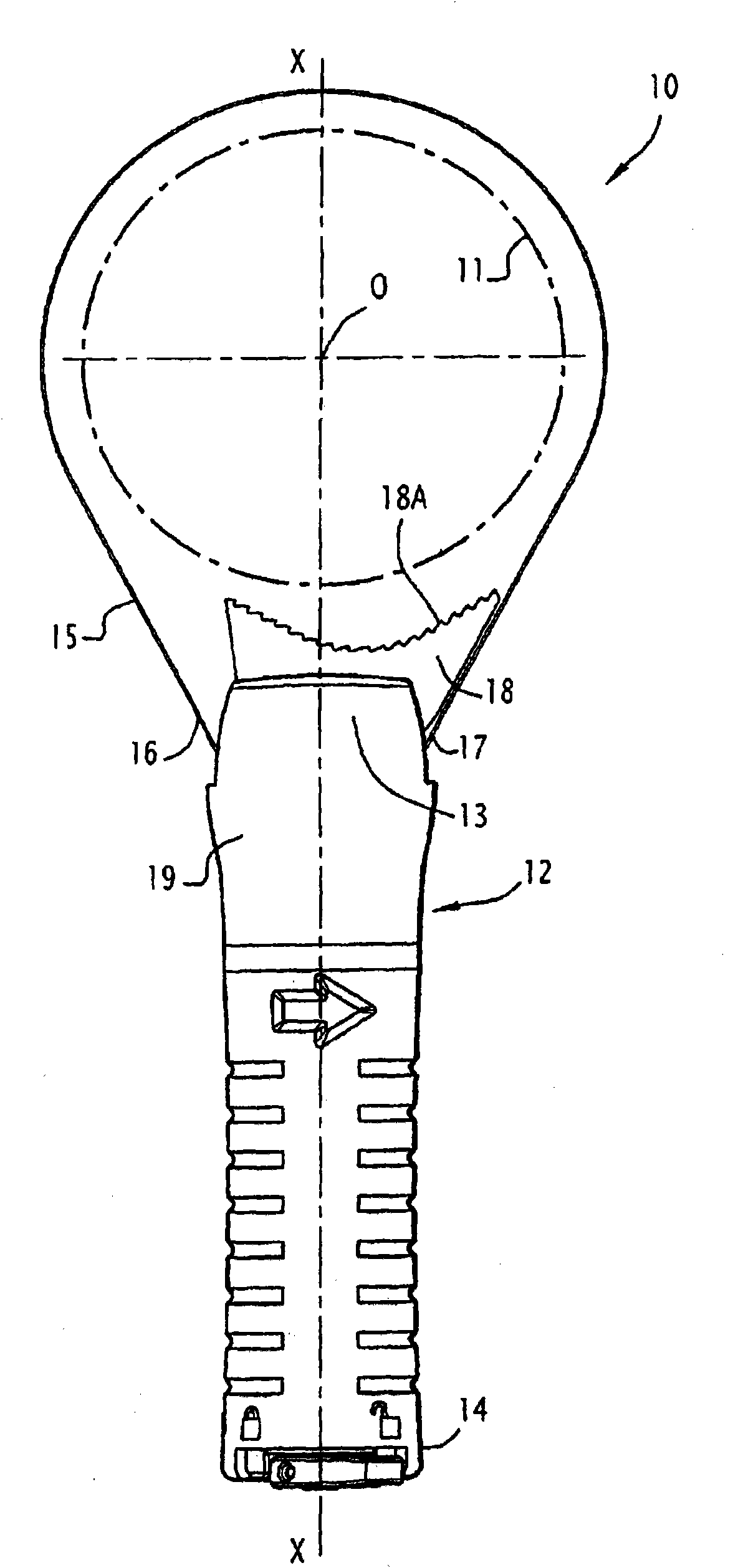

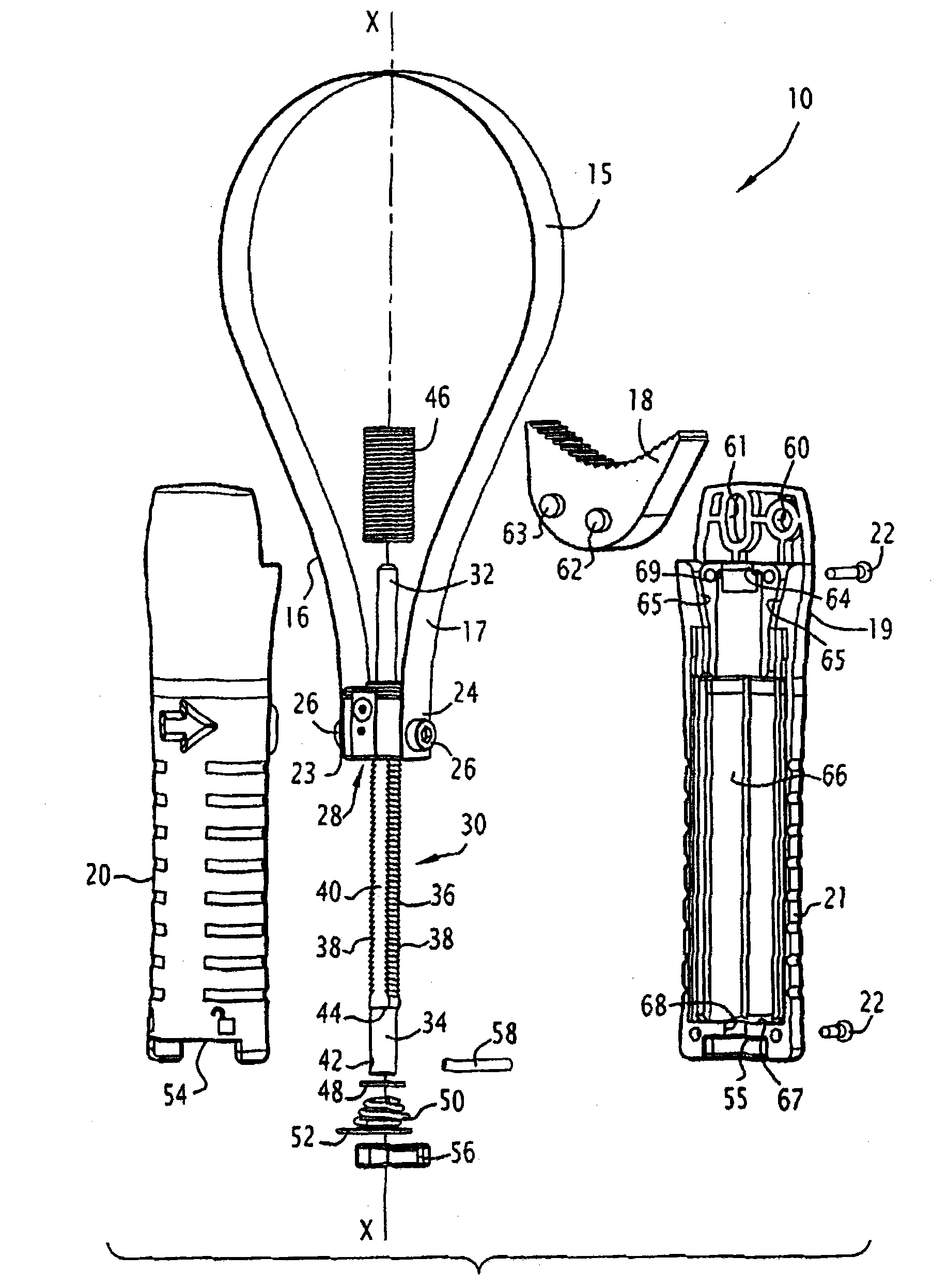

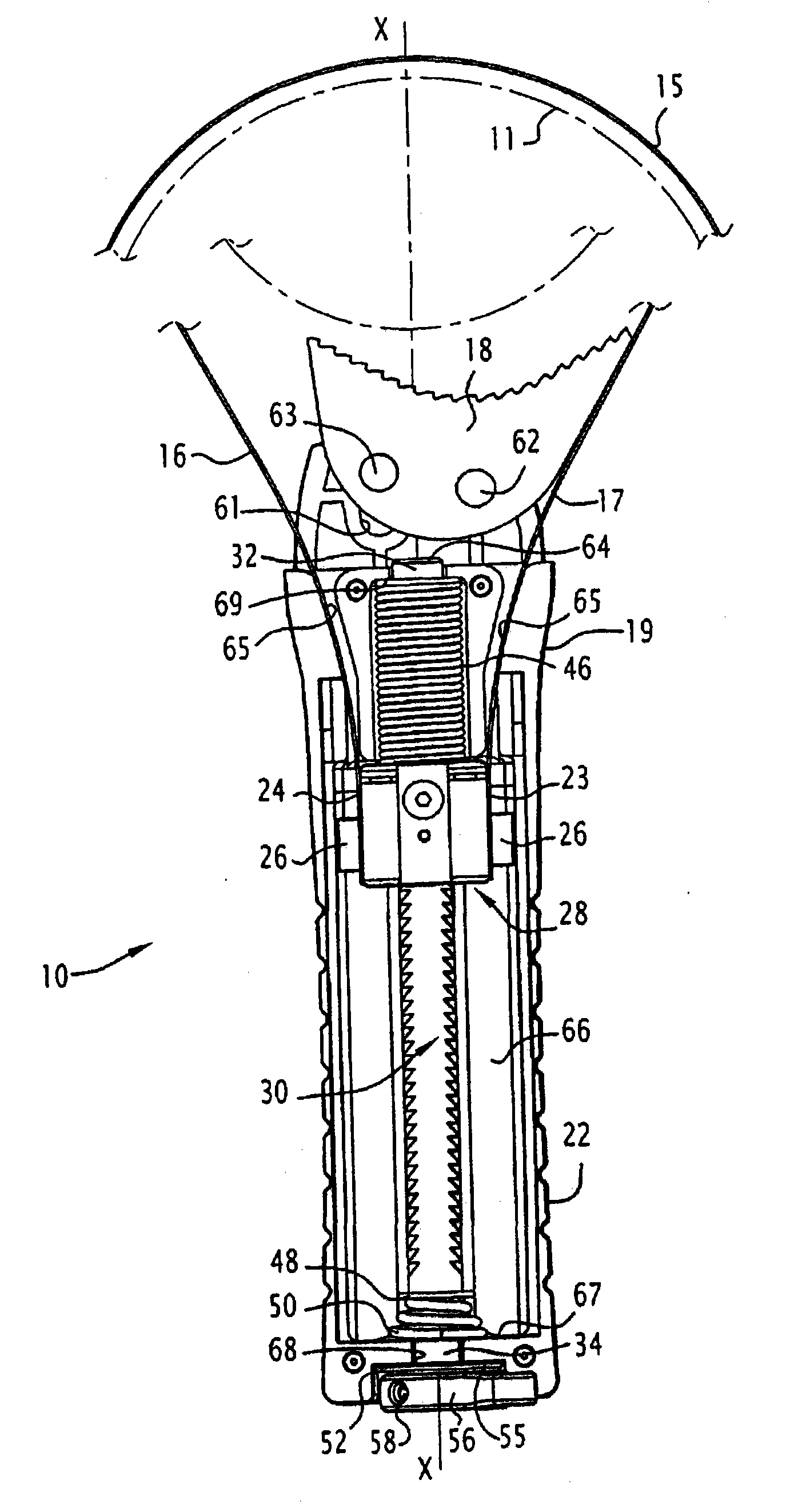

[0042] exist Figure 1 to Figure 12 The band-type pipe wrench 10 shown in is mainly used for dismantling and concomitantly tightening generally cylindrical objects 11, in particular oil filters, the diameter of which can be within a wide range by turning the pipe wrench Variations, such as a diameter of 64 mm to 106 mm in the embodiment shown.

[0043] To describe the pipe wrench 10 more conveniently, it is assumed that the pipe wrench is placed in the orientation shown in the figure, which extends along the longitudinal axis X-X, and the axis O of the filter 11 is located above the handle of the pipe wrench.

[0044] exist figure 1 Here, a band pipe wrench 10 comprises a handle 12 having a distal portion 13 and a proximal portion 14, the distal portion 13 forming a forked joint with wings parallel to the plane of the drawing.

[0045] The strap 15 is in particular a metal strap and forms an endless strap, the strap 15 comprising two end pieces 16 and 17 connected to the han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com