Tool board access device for pcb pressing

A technology for accessing devices and tools, applied in storage devices, transportation and packaging, etc., can solve the problems of no online transmission, no function of identifying the type of tool board, troublesome operation of the tool board, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

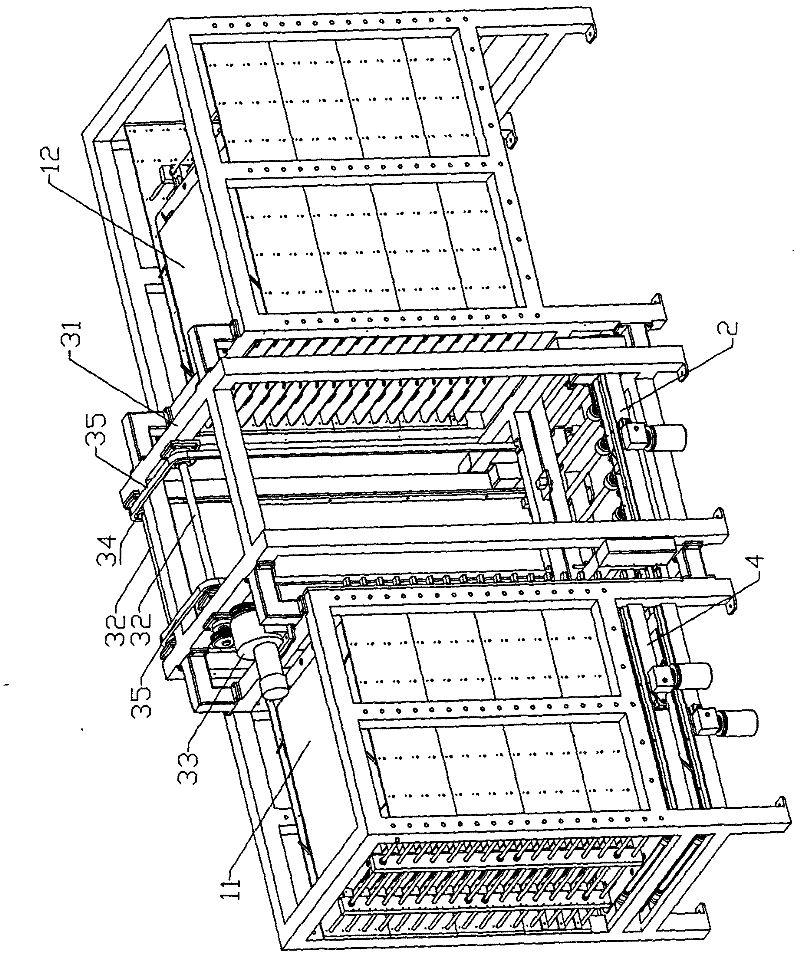

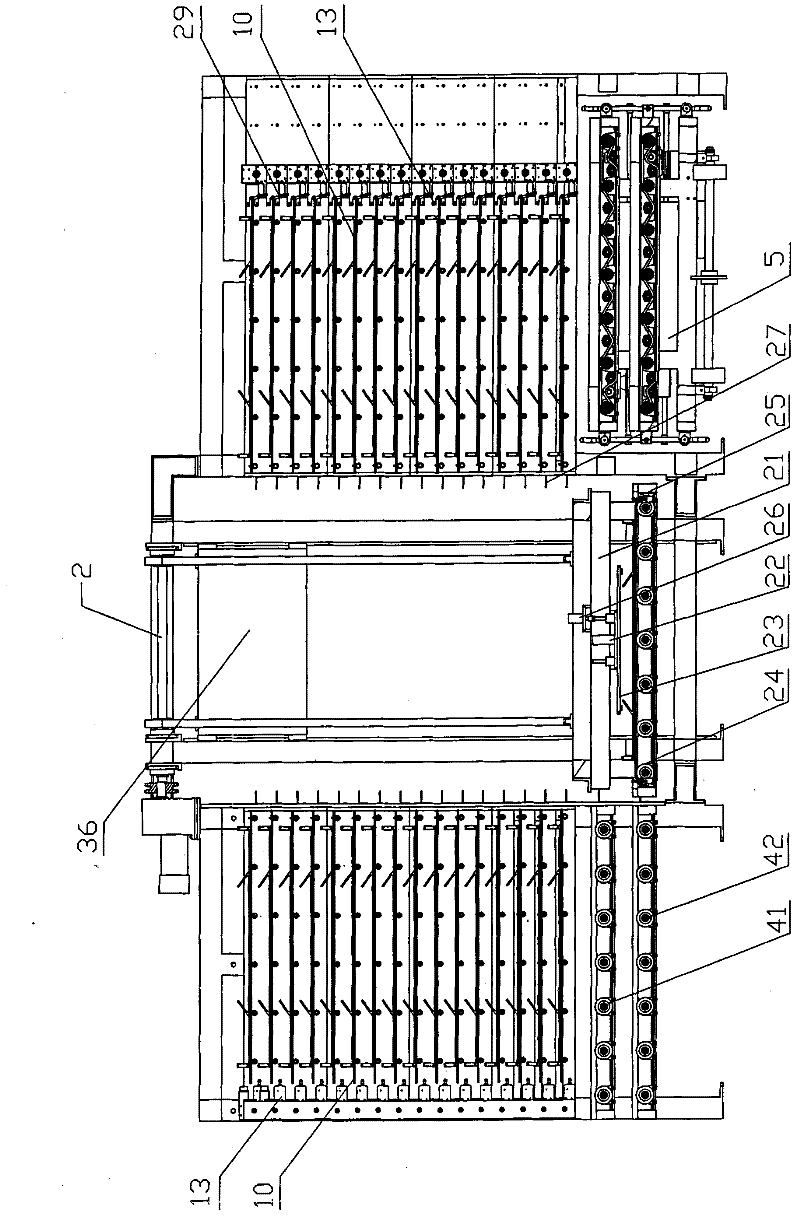

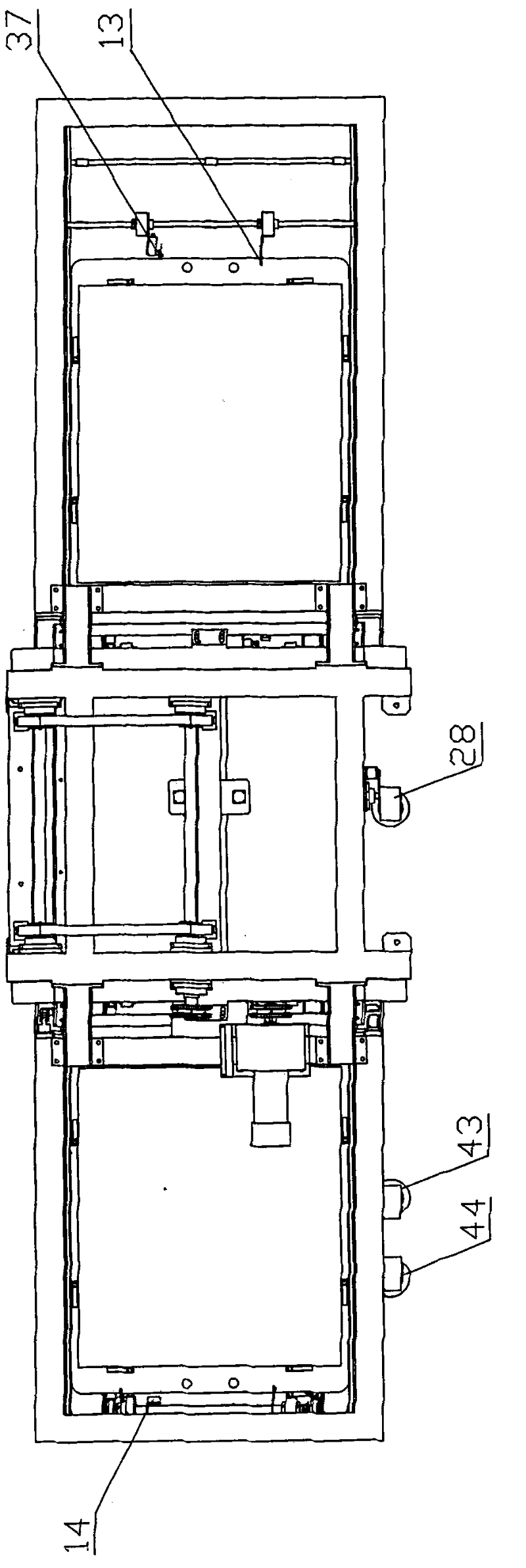

[0021] Refer below Figure 1-Figure 4 Describe in detail an embodiment of the tool plate access device for PCB lamination provided by the present invention; Take the location, specifically:

[0022] The storage unit includes a first storage unit 11 and a second storage unit 12 arranged side by side, and an access device 2 is arranged between the first storage unit 11 and the second storage unit 12, and the top of the access device 2 A vertical lifting mechanism 3 is connected, and a first horizontal conveying device 4 docked with the production line is arranged below the first storage part 11, and the access device 2 is driven by the vertical lifting mechanism 3 to make any access The tool board in the position is transferred to the first horizontal transfer device 4 or the mobile transfer trolley 5 parked under the second storage part 12, and is transported by the first horizontal transfer device 4 or the mobile transfer trolley 5 to the production line, and vice versa.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com