Gear foaming plug

A foaming plug and gear technology, applied in the field of special foaming tools, can solve the problems of inconvenient operation, cumbersome and clumsy, non-sealing, etc., and achieve the effect of simple and light structure, good sealing effect, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

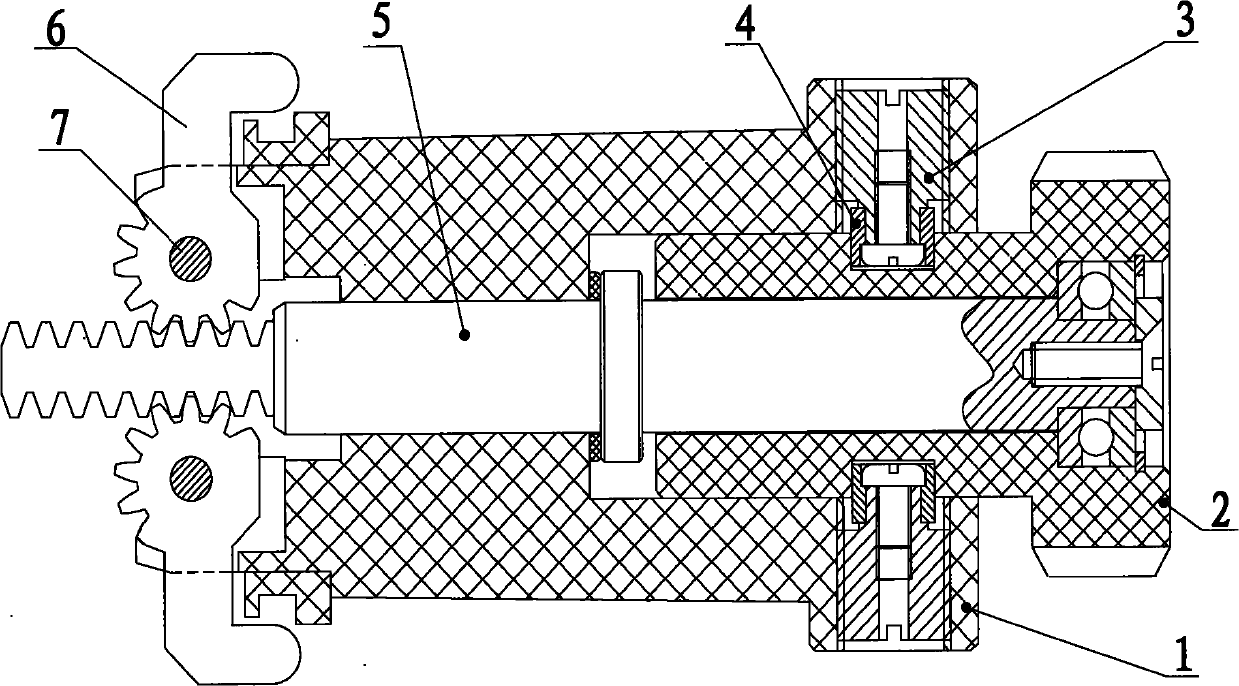

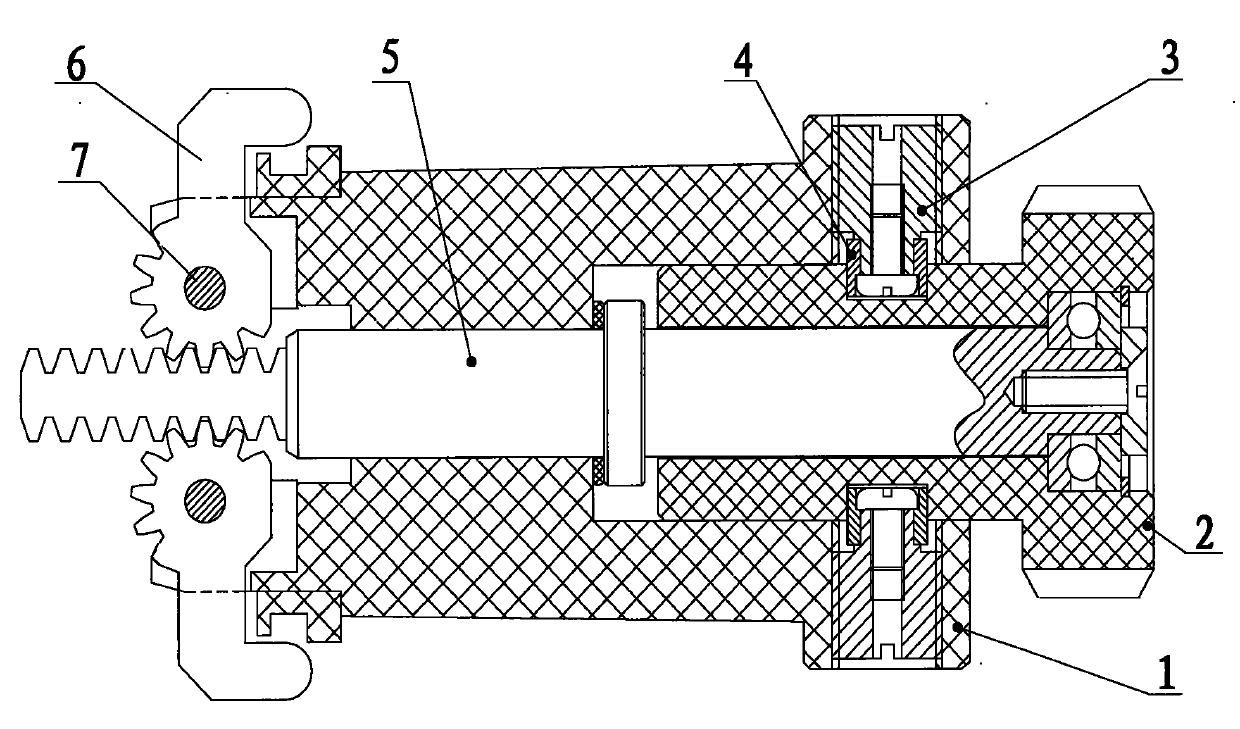

[0010] Such as figure 1 As shown, the gear foam plug of the present invention includes a rotary self-locking mechanism and a rack and pinion mechanism. The rotary self-locking mechanism is composed of a twist sleeve 2, a plug body 1, a screw plug 3 and a roller sleeve 4. The rack rod 5 is composed of a gear claw 6 and a hollow rivet 7. The rack rod 5 is inserted into the hollow plug body 1. One end of the rack rod 5 is a rack, and the other end is connected with a twist sleeve half inserted into the plug body 1. 2. It is connected and fixed. The plug body 1 rests on the two sides of one end of the rack rod 5. A gear claw 6 is movable and fixed through a hollow rivet 7. One end of the gear claw 6 meshes with the rack on the rack rod 5, and the other end For the valgus claw. There are two screw holes on the inner wall of the plug body 1, and a screw plug 3 is installed in the hole, and a rolling sleeve 4 is installed outside the screw plug 3. Realize rotation self-locking.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com