Method and device for evaluating exhaust gas temperature in motor vehicle

A technology for exhaust temperature and motor vehicles, which is applied in the direction of machines/engines, electrical control, mechanical equipment, etc., and can solve problems such as unreliable and weakened requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention will be explained in more detail below with the aid of preferred exemplary embodiments and with reference to the drawings.

[0019] The following abbreviations are used in this manual:

[0020] T o Turbine outlet temperature (in Kelvin K);

[0021] T i Turbine inlet temperature (in Kelvin K);

[0022] T3 Exhaust temperature (in Kelvin K);

[0023] P o Turbine outlet pressure (in bar);

[0024] P i Turbine inlet pressure (in bar);

[0025] NT turbocharger speed (in revolutions per minute rpm);

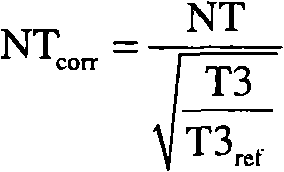

[0026] NT corr Corrected turbocharger speed (in revolutions per minute rpm);

[0027] VNT impeller position (in % or angle) (optional);

[0028] γ ratio of specific heat (dimensionless);

[0029] n TS total / static efficiency (values range from 0 to 1);

[0030] n M Mechanical efficiency (values range from 0 to 1).

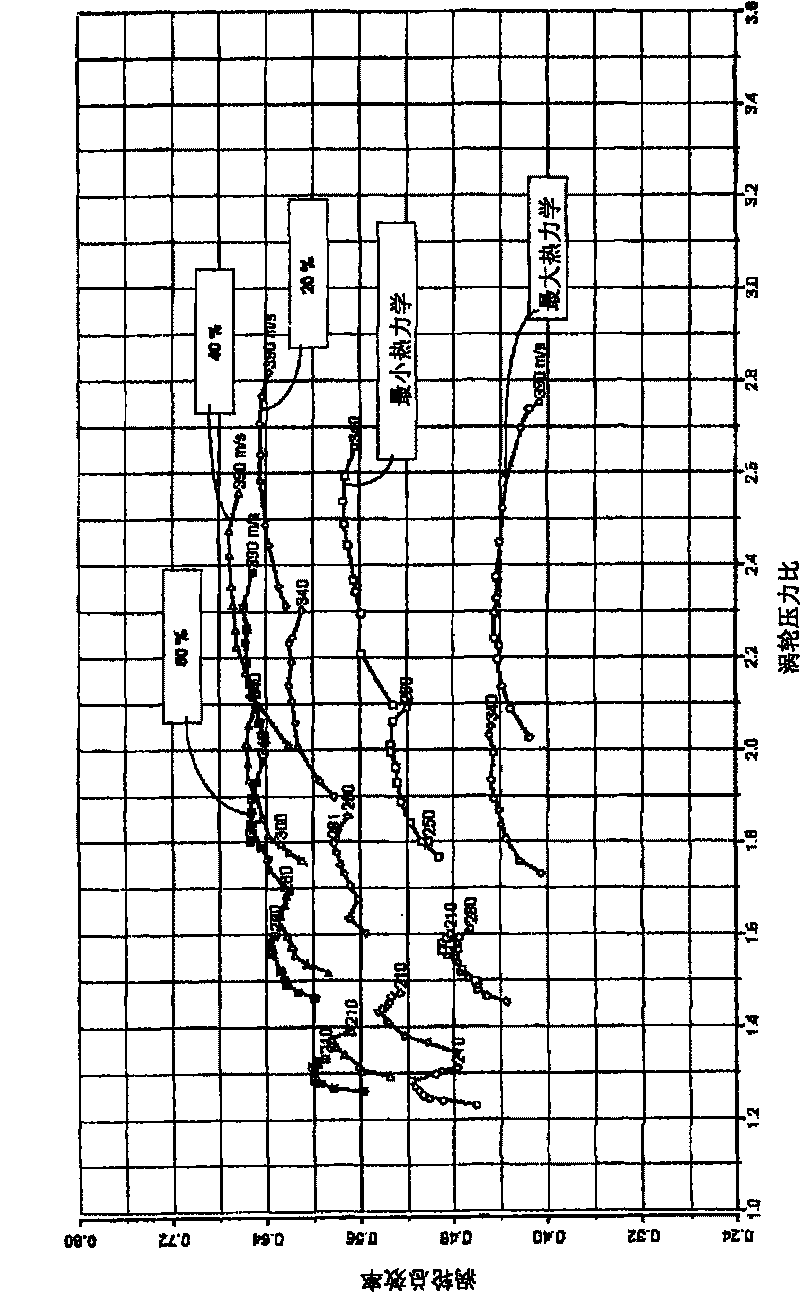

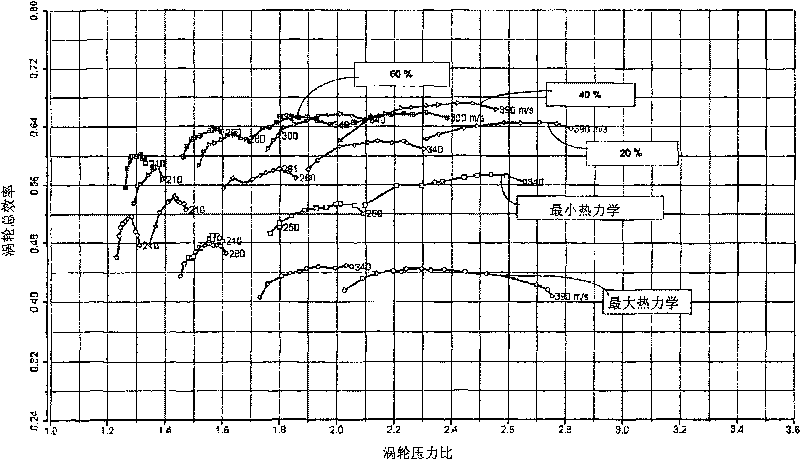

[0031] According to the invention, the turbocharger speed is determined by using a turbocharger s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap